Polyethylene Plays Vital Role in Conservation

Water is never a concern to most people until they turn the faucet on and nothing comes out.

For more than 60 years, McElroy has committed to providing innovative, quality products and services.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

For more than 60 years, McElroy has committed to providing innovative, quality products and services. McElroy designs and manufactures a comprehensive line of fusion equipment for joining thermoplastic pipe including high-density polyethylene (HDPE).

The company offers a complete range of accessories that are designed to increase onsite productivity and efficiency. Its commitment to the industry includes an extensive training program through McElroy University to ensure that operators and inspectors develop best practices in the quality and reliability of fused pipe systems.

HDPE and heat-fused joints have played a major role in the mining industry. The combination of thermoplastic pipe, which does not corrode, and heat fusion offers a cleaner solution without the risk of leaks. HDPE is resistant to the abrasive acid water often found in mines. The fusion machine heat welds two pipe surfaces together to create one monolithic pipe. This eliminates the chance for leaks to develop at the joints. Mining sites worldwide have chosen this combination for a variety of reasons.

Many times thermoplastic pipe gets called into service to carry liquids, gases and even rough solids, such as slurry. HDPE is often preferred because of its flexibility which allows it to withstand ground movement as occurs with earthquakes and shifting soils.

McElroy designed its first fusion machine in 1969. The company portfolio has since expanded to cover pipe sizes from 0.5in copper tube size (CTS) to 2,000mm, which forms the most comprehensive range of any fusion equipment manufacturer. Fusion equipment is available in various models from rolling and tracked models to carriage-only models, to accommodate specific jobsite requirements.

The creation of the McElroy TracStar® in the late ‘90s was inspired by the needs of the mining industry to create the world’s first self-contained, self-propelled track-mounted machine. Users benefit from its mobility and hydraulic assistance on key functions with requires less manpower and makes it more productive.

In 2013, McElroy set out on a completely new design to meet large-diameter challenges with the increasing use of pipe up to 2000mm. The Talon™ 2000 is a self-propelled machine with a jaw design that self-loads pipe from the ground, positions it to be fused and moves from joint to joint down the pipeline. The new method for handling pipe known as pipelining provides a safer, more efficient way to fuse large pipe.

McElroy believes in providing solutions to problems; therefore, in addition to fusion machines, McElroy provides a variety of accessories and productivity tools that can significantly improve jobsite efficiency. Examples include its Pipe Stands and Low Profile Rollers, as well as the PolyHorse® and the MegaMc® PolyHorse pipe handling systems, which consist of a series of adjustable racks to store and help move and align pipe on jobsites. These adjustable racks provide a less hazardous environment for handling pipe bundles, and reduce manpower costs while enhancing jobsite productivity.

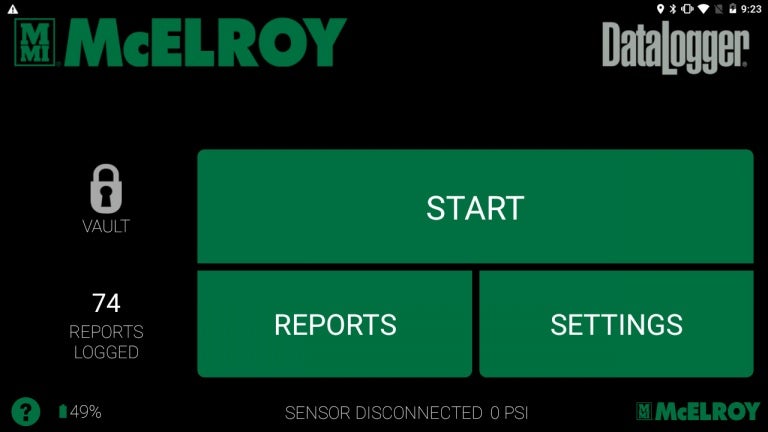

Quality testing and quality assurance can be a tremendous benefit to any jobsite. The McElroy DataLogger® gives operators the ability to record the parameters of the pipe fusion process to determine if proper procedures have been followed. Data elements such as time, temperature and pressure are recorded on this ruggedized tablet and the latest DataLogger also allows operators to scan data and capture photos and GPS coordinates.

The DataLogger can be used in combination with the Vault™ which is a secure web-based server that stores fusion joint data. This allows users to access their joints from any location with internet access and use a variety of analytical tools.

For quality testing, there are a variety of options available. McElroy’s Guided Side Bend Tester and In Field® Tensile Tester are two such tools that allow onsite qualitative testing to ensure joints meet the appropriate standard. If a laboratory type test is required, McElroy also offers the McSnapper® to destructively test impact resistance.

McElroy University provides training through a number of methods. Training is offered at its facilities in Tulsa, Oklahoma, through certified instructors throughout the US, online courses as well as onsite custom training per client request. Classes include operator qualification, troubleshooting and rebuild and inspector training.

Each class includes a combination of classroom and hands-on sessions, followed by after-class testing to ensure that students understand the proper concepts and procedures.

Students who successfully pass the tests receive a McElroy University operator qualification which is valid for two years.

For more information about McElroy equipment, go to www.mcelroy.com.

Water is never a concern to most people until they turn the faucet on and nothing comes out.

Piping made from polyethylene is a cost-effective solution for a broad range of piping problems in municipal, industrial, marine, mining, landfill, duct, and agricultural applications.

During the fusion process, the most significant amount of time for each joint is attributed to cooling procedures.

McElroy, the world’s leading designer and manufacturer of thermoplastic pipe fusion equipment, is pleased to announce that Steve Caldwell has been promoted to Vice President, Human Resources.

McElroy, the world’s leading designer and manufacturer of thermoplastic fusion equipment, is pleased to announce that Chris Zenthoefer, the company’s Director of Digital Strategy, has been promoted to Vice President of Product Strategy.

TULSA, OK – McElroy is proud to announce its participation in the latest installment of the Association of Equipment Manufacturers’ (AEM’s) acclaimed Through the Lens photo series, which shines a spotlight on the skilled men and women powering America’s equipment manufacturing industry.

TULSA, OK – On Friday, U.S. Rep. Kevin Hern (R-OK) visited McElroy Manufacturing in Tulsa, Oklahoma for a town hall meeting and a tour of one of McElroy’s manufacturing facilities.

TULSA, OK – On Wednesday, May 7, 2025, McElroy was recognized for its commitment to workplace safety and its participation in the Occupational Safety and Health Administration (OSHA) Safety and Health Achievement Recognition Program (SHARP).

McElroy, the world’s leading designer and manufacturer of thermoplastic pipe fusion equipment, now offers German as a language option for its website.

McElroy, the world’s leading designer and manufacturer of thermoplastic pipe fusion equipment, is thrilled to announce that Volker Köhler will play an integral role in helping McElroy grow its business in Europe and around the world.

McElroy, the global leader in the design and manufacture of thermoplastic fusion equipment, has launched three new micro-websites dedicated to distributors and customers in Mexico, Peru, and Chile.

McElroy, the world’s leading designer and manufacturer of plastic pipe fusion equipment, announced its digital innovations at INFUSION24, the company’s annual industry conference in Tulsa, Oklahoma.

McElroy, the world’s leading designer and manufacturer of thermoplastic fusion equipment, has announced the addition of Bob Biffle, Mike Lee, and David Lee to the 2024 Fusion Hall of Fame.

McElroy, the world’s leading designer and manufacturer of plastic pipe fusion equipment, will have one of its latest innovations, the Tritan™ 560, on-site in Booth #12503 at MINExpo Sept. 24-26 in Las Vegas, Nevada.

On Monday, July 15, 2024, McElroy was recognized for its commitment to workplace safety and its participation in the Occupational Safety and Health Administration (OSHA) Safety and Health Achievement Recognition Program (SHARP).

McElroy, the world’s leading designer and manufacturer of pipe fusion equipment, on Wednesday hosted a ribbon cutting to commemorate the opening of the McElroy Museum.

McElroy, the world’s leading designer and manufacturer of thermoplastic fusion equipment, has launched a website dedicated to the Australian distributors and customers at www.mcelroyfusion.com.au.

Building off the strong legacy of McElroy’s three existing TracStar® iSeries machines – the TracStar® 630i, 900i, and 1200i – McElroy is thrilled to announce the addition of the TracStar® 412i and TracStar® 618i.

McElroy has once again been recognized for its commitment to workplace safety. At the 2023 Oklahoma Safety Conference, McElroy was named the recipient of the prestigious Pinnacle of Safety Award from the Oklahoma Safety Council.

EES Engineering is based in Khoroo, Mongolia and caters to the country’s fast-growing mining industry.

SHARP is an on-site consultation programme that offers confidential occupational safety and health services to small and medium-sized businesses in the US, free of charge.

This new facility will provide an additional 193,000ft² of space for McElroy operations, including a planned showcase assembly operation responsible for roughly 40% of McElroy’s annual business.

Bluegreen joins an extensive list of McElroy distributors around the globe that supply McElroy's industry-leading thermoplastic butt fusion equipment.

The Tritan™ 560 is the newest member of the McElroy lineup.

As McElroy’s UK International Business Manager, Palaiologos will work alongside customers with their machinery.

In his capacity as Director of Digital Strategy, Zenthoefer will assist in crafting McElroy’s technological approach to its equipment.

Looking forward to seeing you in person!

McElroy University provides a wide range of training to address needs across the industry.

Get To Know The New TracStar® i Series from McElroy,

No need to book your flights, the Inspector Qualification class offered through McElroy University is now available exclusively online.

McElroy builds on the success of the TracStar® legacy with the introduction of the TracStar iSeries bringing a new level of performance and reliability to the pipe fusion industry.

McElroy, the leading manufacturer of pipe fusion machines used in the construction of thermoplastic pipelines worldwide, is pleased to announce that Vikrant B Sanglikar will be joining the team as the new Country Head for its India office.

Exhibited as a virtual event, this year's INFUSION saw two shining stars bridging the divide - the new TracStar® iSeries and the DataLogger® 7.

McElroy offers advancements in battery technology, processing power and integration capabilities with its release of the new DataLogger 7.

Shell announced in October of 2018 its plans to develop more onshore natural gas fields in Queensland, Australia.

We have added a helpful new DataLogger and Vault FAQ section to our website. These how-to’s address some of the most common questions and explain the new features for both platforms.

Learning knows no bounds at McElroy University. For a limited time, you can still receive training directly from the fusion experts with our new online learning series!

The DataLogger 6 now offers a guided workflow to document the details of your pressure tests along with a digital graph of the process.

McElroy brings productivity improvements and exciting new features to the DataLogger 6 that allow users to document and analyse even more of their job sites.

The biggest stars of INFUSION19 were the machines! Guests who came to Tulsa for three days of peace, love and fusion had the opportunity to touch, see and interact with an even greater variety of polyethylene and polypropylene products at the Product Showcase this year.

When it comes to sidewall fusion, no tool tackles the job better than a McElroy Sidewinder.

McElroy’s largest machine in the TracStar lineup has everything the operator needs to fuse 16in OD to 48in OD (450mm to 1200) pipe efficiently and effectively.

McElroy designs and manufactures a wide range of fusion equipment for joining thermoplastic pipe, such as high-density polyethylene (HDPE), fusible PVC™ and polypropylene.

McElroy has updated their DataLogger 6 with additional features.

Outlet fusion just got bigger with the Hornet XL. McElroy brings this industry-first, all-in-one tool for polypropylene outlet fusion up a size with branches from 63mm to 160mm on to main sizes 110mm and larger.

Here are the forthcoming shows that will exhibit McElroy's solutions.

McElroy fusion machines have a new home in the Middle East with the opening of Plastic Pipes Welding’s facility in Dubai.

The McElroy DataLogger 6 offers expanded data collection capabilities and exciting new features with a free software update that is now available.

Manual fusion data logging capability, improved graph display and more!

The TracStar Series 2 pipe fusion machines are self-propelled vehicles equipped with a 4-jaw carriage that is used to butt fuse thermoplastic pipe by applying heat and pressure.

McElroy, a leading manufacturer of pipe fusion equipment, has unveiled the new Polygon, a versatile tool uniquely built for the needs of the mechanical, plumbing and HVAC piping industry.

McElroy has designed the first all-in-one fusion tool for outlet fusion of polypropylene pipe, the Hornet™.

A new product by McElroy called the QuickCamp™ System was successfully tested recently at a jobsite in Canada, attracting area contractors and engineers who travelled there to get a first-hand look at the unique shelter and pipe-handling system at work.

McElroy, a leading manufacturer of high-density polyethylene (HDPE) pipe fusion equipment, is pleased to add Fortiline Waterworks to its growing network of distributors.

McElroy is pleased to announce the addition of a new distributor to serve pipe fusion machine customers throughout Louisiana.

The release of the TracStar® 1200 brings the largest pipe fusion capability to date in McElroy's popular line of self-propelled, track-mounted fusion machines.

McElroy has unleashed the Talon™ 2000, designed to revolutionise the way large-diameter thermoplastic pipelines are built.

McElroy, which manufacturers one of the most extensive lines of thermoplastic fusion machines used worldwide, has opened an office and demonstration facility in Bangalore, India, devoted to sales, rentals and technical service.

McElroy has further improved jobsite efficiency with the creation of the OneFit™ Inserts.

The launch of McElroy's In-Ditch 48 brings fusion capability to confined work settings using large-diameter pipe.

McElroy has brought hydraulic capability to its Pipe Stand line for 4in to 20in (200mm-500mm) pipe to help align thermoplastic pipe more efficiently on butt fusion jobsites.

McElroy is pleased to bring wireless capability to the DataLogger® 5, which gives pipe fusion operators the ability to upload data to the DataLogger Vault™, where it can be reviewed and analysed in real-time from anywhere in the world.

Cities across the country are facing the costly and urgent task of replacing antiquated water systems that disrupt traffic and interrupt service due to countless, expensive and all-too-familiar water line breaks.

McElroy has recently announced the addition of three new distributors that will serve domestic and international customers from east to west.

Built for the ditch.

The number one for the job site.

The Standard since 1975.

Built for the ditch.

Flexible to meet the demands of any job site.

The next generation of TracStar® machines offers the industry a sophisticated, rugged and productive fusion machine.

The Talon 2000 is a self-propelled vehicle with the unique ability to safely lift pipe from the ground, position it to be fused and move from joint to joint down the pipeline.

The Tritan™ 560 aids in pipe positioning, allowing for more flexibility and increased performance and productivity.

McElroy introduces the Talon™ 2000 - for 54” OD to 2000mm OD pipe fusion.

Step inside McElroy's 'world of machines and mechanisms' as we learn all about the Talon - the machine that completely flips traditional fusion equipment on its head.