AKW Equipment and Process Units

AKW Apparate + Verfahren GmbH is a medium-sized, privately owned company focussed on process engineering and equipment, as well as on plant engineering, construction and service.

AKW Apparate + Verfahren GmbH (AKW A+V) offers services in process engineering and equipment, as well as plant engineering, construction and service.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

AKW is a German based medium-sized, privately owned company with focus on wet mechanical solutions for an optimum and responsible valorizing of primary and secondary resources.

Since the foundation of AKW Equipment and Process Design in 1963, innovation, new product ideas and technologies have turned the company into a global operating enterprise with its headquarter in Hirschau, offices in Shanghai and Dubai as well as agencies in several countries worldwide.

Our services are applicable to hydrocyclones, silica sand, kaolins, glass sand, high-performance thickeners, and speciality sand. They are also suitable for wet mechanical treatments, free-fall and upstream classifiers, and high-performance attrition cells.

AKW Equipment + Process Design accompanies its customer starting from the problem identification, over process design up to the implementation and startup of the processing plant. Through service assignments, audit visits and supply of spare and wear parts, AKW Equipment + Process Design assists to keep the plant performance on its high level for the whole lifetime.

AKW A+V has a state-of-the-art technical laboratory to respond to clients’ procedure and process needs. The research and development team works closely with universities and research institutes to ensure a high standard of technical development in the process chain and process engineering; this also allows the company to offer a wide range of test facilities, including sample and materials analysis.

AKW A+V designs uniquely coordinated solutions for each individual project. The company uses its engineering activities to assist clients through all stages of planning, from analysis and test reports to pre-basic, basic and detail engineering as well as the commissioning of the equipment, process units or turnkey plants.

The applied processes are based on equipment and process units developed by AKW A+V. The company manages the conception and application of its own products, as well as those designed for integration into a client’s purchased products.

AKW A+V acts as a partner, offering support to its clients beyond the delivery and commissioning.

The after-sales service covers a reliable supply of spare and wear parts, maintenance and repairs, audits, training, equipment inspection as well as rebuilding, upgrades and adjustment to new feed / end product specifications.

AKW A+V services a broad range of industries, including:

AKW Apparate + Verfahren GmbH is a medium-sized, privately owned company focussed on process engineering and equipment, as well as on plant engineering, construction and service.

AKW Apparate + Verfahren GmbH will be exhibiting 3D models of its equipment at bauma, the world’s leading trade fair for construction, building material and mining machines, construction vehicles and construction equipment.

AKA-JIG jig machines are used to separate impurities from raw materials and industrial wastes in accordance to their density differences.

AKW Apparate + Verfahren will be exhibiting at this year's Plastics Recycling World Expo, taking place on 11-12 September 2024, in Brussels, Belgium.

AKW Apparate + Verfahren GmbH, a leading provider of engineered solutions and equipment for wet mechanical processing and process water management, has confirmed its attendance at this years IFAT trade fair in Germany.

AKW A+V has confirmed its attendance at this year's MINEROC Mining Conference, taking place on 5th and 6th March 2024.

AKW Apparate + Verfahren GmbH has confirmed its attendance at the CRU Phosphates Conference next month.

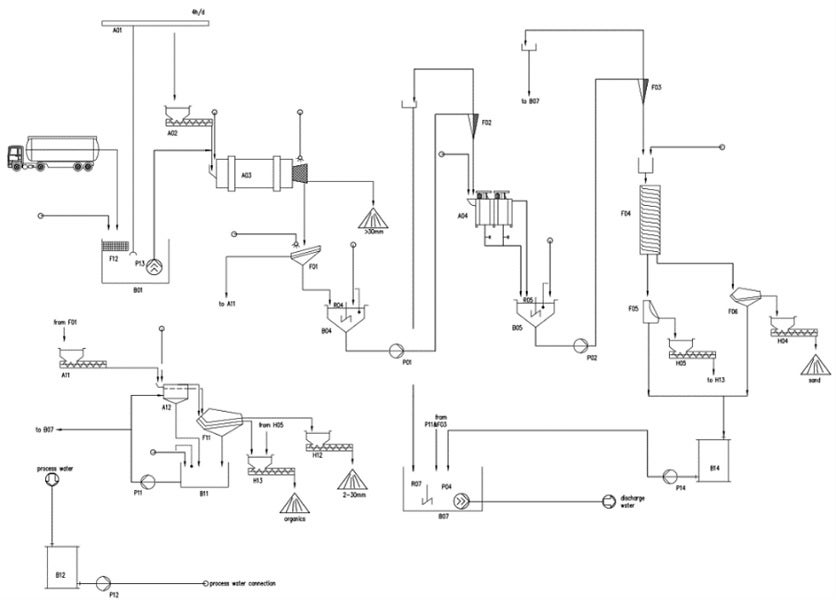

After water, sand is the world’s most consumed natural raw material. Since sand is not only needed for buildings or roads, but also for glass, cosmetics or smartphone screens, the demand far exceeds natural resources.

Best-in-class design means, in particular, to care about the process water loop by developing solutions ensuring (1) the use of minimum water amount per ton of material treated, and (2) the maximizing of the process water recovery.

One of the main achievements and significant milestones reached refers to the signing of the supply on a turnkey basis of a treatment plant for the valorizing of sewage sludge from dredging pipelines.

The AKW Equipment + Process Design team was recently on tour in France, to finalize with his customer the installation conditions of its new and revolutionary AKA-SILT system.

The team is proud to announce that we received our new QM-Certification, confirming that we have established and maintained a quality management system according to the standard ISO 9001: 2015.

AKW Equipment + Process Design has the pleasure to announce that Mr Thibaut Richard has been appointed as managing director.

AKW Apparate + Verfahren GmbH has successfully closed a multi-million euro deal for the supply of hydrocyclones and pumps going into the salt industry in Russia. The equipment deliveries will start from early 2016 until end of 2018.

AKW Apparate + Verfahren GmbH has strengthened its presence in the Middle East and confirms its position of a key market reference for high-quality and high-performance sand washing processing units, by signing a new supply agreement with a major local producer.

AKW Apparate + Verfahren GmbH will be presenting at the SIM exhibition in Bordeaux and the MENA mining show in Dubai, where the company will exhibit its experience, know-how, motivation and compliance with high international standards in quality and service.

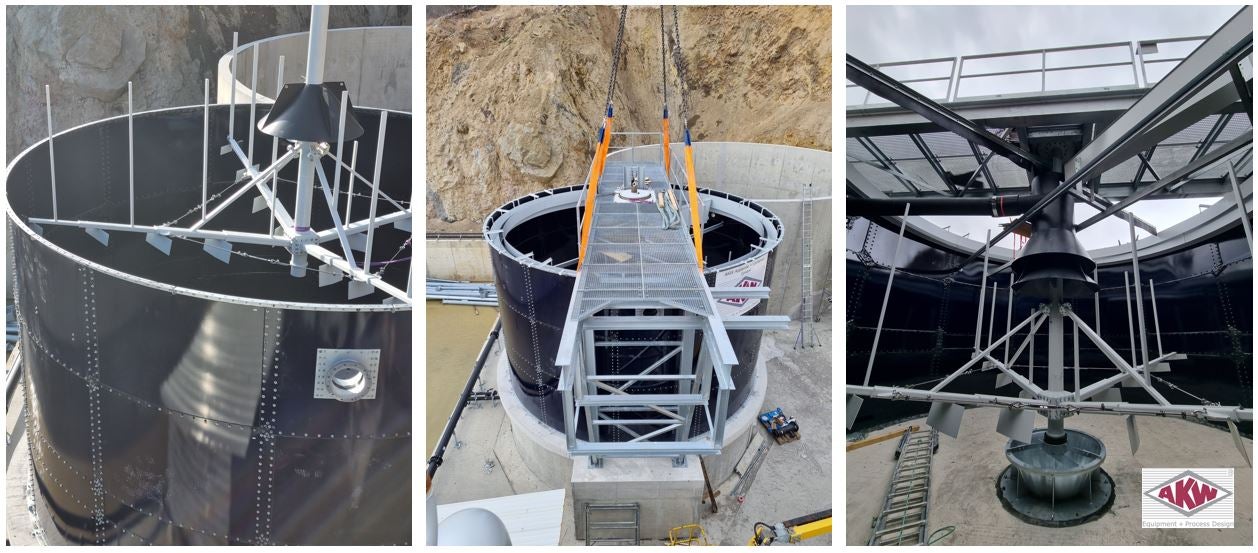

AKA-SET high performance thickeners are used for mainstream process water treatment and slurry thickening. Available as flat or conical versions.

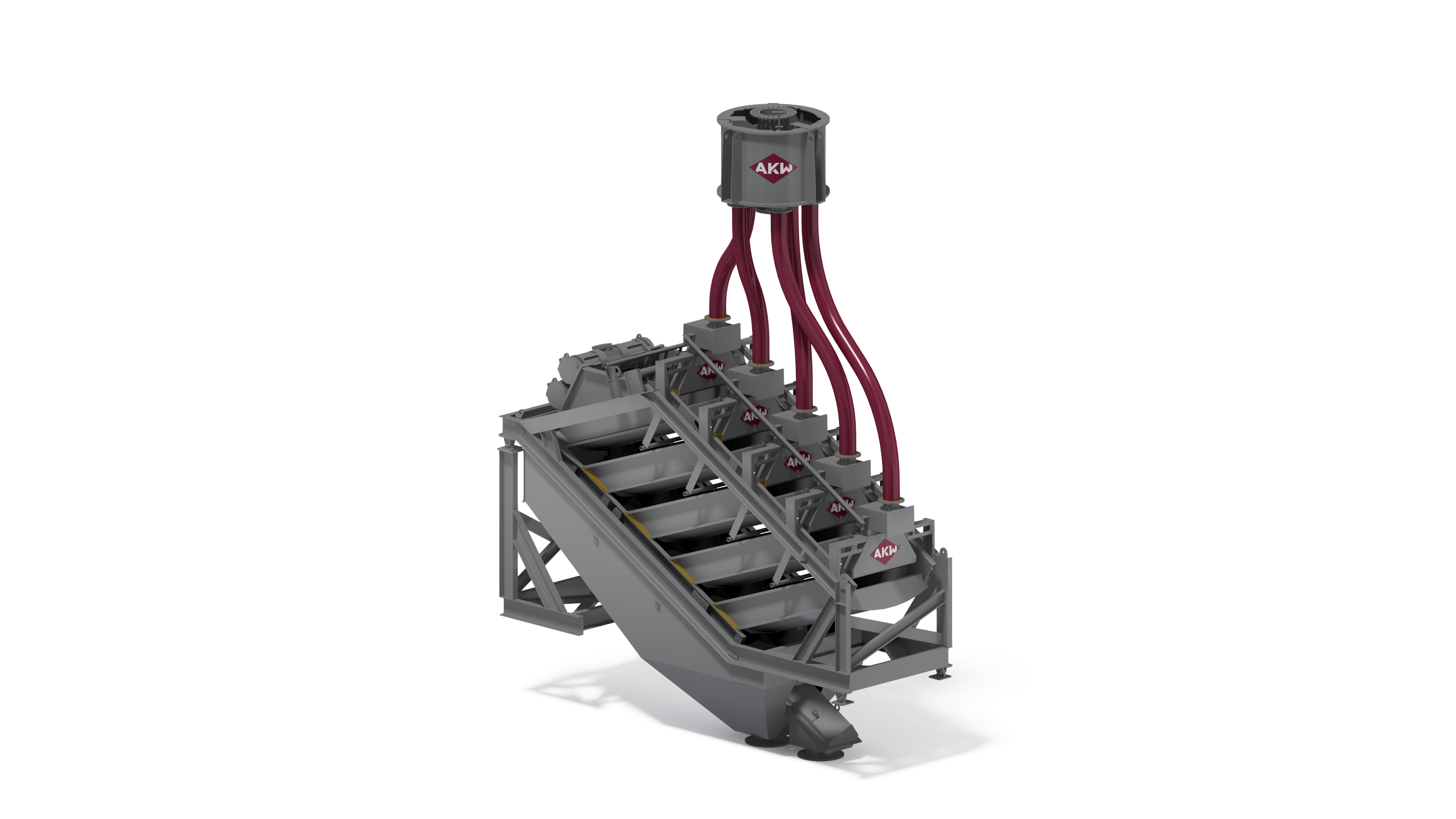

AKOREL free-fall classifiers are used to correct the sieve curve of raw sand ranging from 0 – 4 mm according to customer’s requirement.

AKA-SIZER upstream classifiers are used to produce products with sharp cut sizes within the range of 0.1 to 0.8 mm.

Processing of raw material begins in the washing drum. A good wetting and washing effect is a prerequisite for a high-quality product. The AKA-DRUM is available in various sizes. Rugged designs for mining and wear resistant rubber or PU lining ensure a long service life time.

AKA-SPIN spirals are used to separate materials (60 μm – 2 mm) according to their different densities.

Hydrocyclones are important and economically viable systems for the wet-mechanical separation, classifying and sorting processes of ores and minerals.

AKA-TRIT attrition cells are used for surface cleaning of sandy materials contaminated with impurities or pollutants.

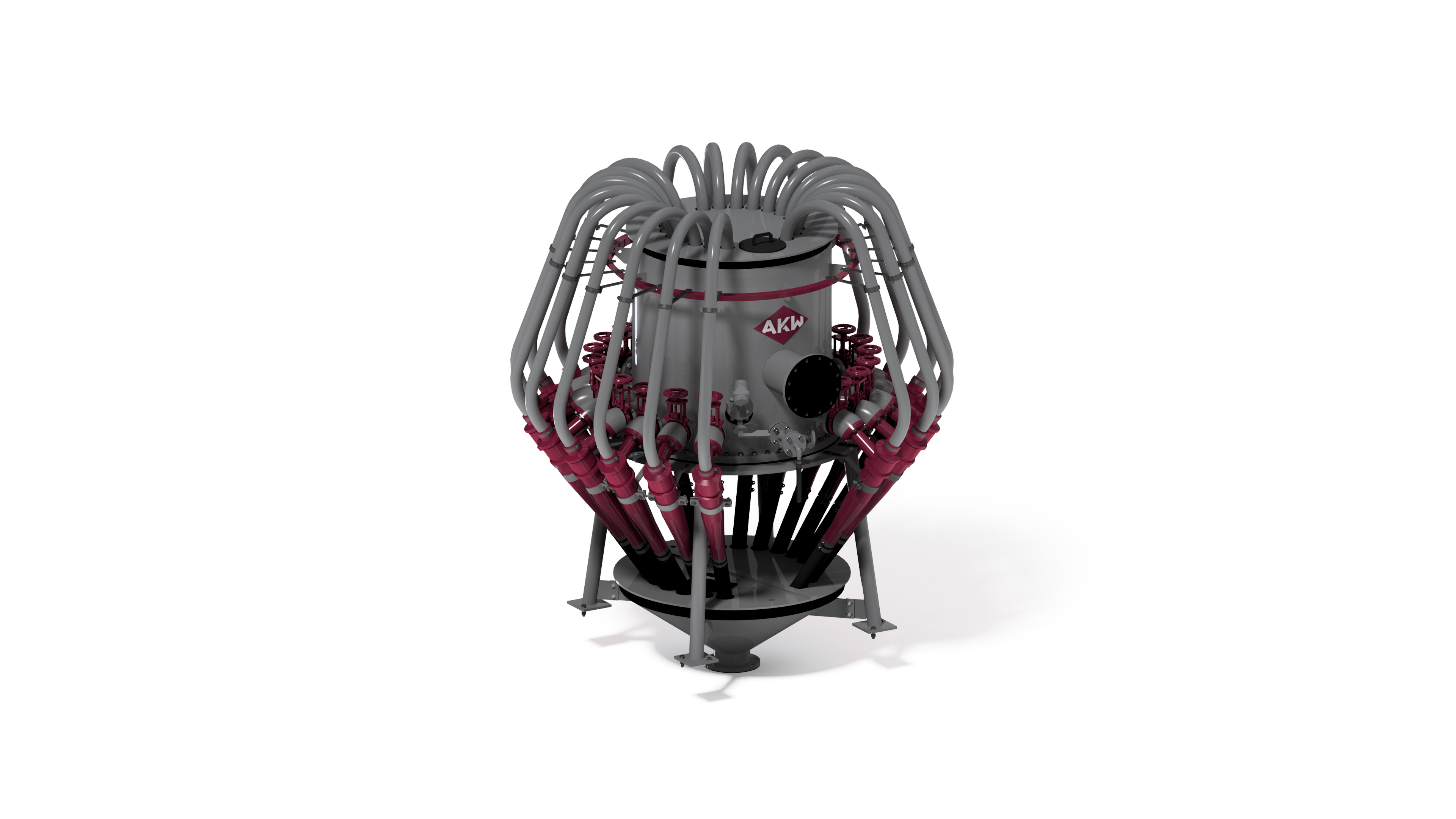

AKA-SPIDER distributors are used to combine several AKA-VORTEX hydrocyclones in linear or annular design to reach a requested process throughput.

AKA-SCREEN fine wet classification screens are used to produce fractions with sharp cut sizes.

AKA-JIG jig machines are used to separate impurities from raw materials and industrial wastes in accordance to their density differences.