Q&A with Eurogomma Marketing and Sales Director Cristian Annoni: Innovators in Customised Polyurethane Screens

We talk with Eurogomma marketing and sales director Cristian Annoni about the Italian company and its innovative polyurethane screens.

EUROGOMMA is a manufacturer of polyurethane screens, including modular polyurethane screens and modular polyurethane screening panels, tensioned polyurethane screens.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

EUROGOMMA is the name of a group of companies all involved in the manufacturing and distribution of elastomer wear resistant products for mining, aggregate processing and industrial applications.

The group started with the establishment of the company Eurogomma di Annoni Luciano under the guidance of the founder Mr. Luciano Annoni in 1975 in Bergamo, Italy.

The principles of the Made in Italy qualified Manufacturing has characterized our history and they are at the base of the global success that we have achieved in more than 45 years.

Our quality is the indispensable characteristic of all our productions, both in our Italian and foreign factories. Our base materials are Italians, our design is Italian and our long experience is an essential part of our success thanks to the elaboration of every new technical proposal through the several applications that we have afforded till now.

Our best sellers are our polyurethane screens which can be offered in different configurations:

The unique polyurethane tensioned screens with Superflow apertures allow users to maximise screening efficiency in every situation. EUROGOMMA engineering and manufacturing methods are flexible and use cutting-edge technology to offer the most competitive solutions to customers worldwide.

EUROGOMMA engineers and manufactures customised polyurethane screens, liners, stators and rotors, fitting all the wear-resistance and screening requirements that customers require worldwide.

The company’s engineering and manufacturing departments use sophisticated CAD software to transform ideas and information into reality.

GET flexy. The unique high-efficiency and non-blinding polyurethane screening system

GET flexy is the new dimension of screening.

The elastic effect of the polyurethane flexible screen panels solve pegging and screen blinding problems by improving the screening efficiency to incredible performance.

With GET flexy, it is possible to provide conventional screen decks of double productivity or larger.

GET flexy is the polyurethane elastic screening system retrofitting every existing screen deck to transform it into a high-efficiency technology.

EUROGOMMA’s fine screening polyurethane screen panels are ideal for the classification of abrasive sand.

Thanks to the superior quality of our polyurethanes, all our screen cloths are wear and corrosion-resistant. Therefore, the polyurethane screen panels have no usage limit and guarantee successful performance in every application, whether oil, mining, waste management.

EUROGOMMA’s fine screening polyurethane panels are used in trash screens for mineral processing, stack sizers, repulp screens and slurry dewatering screens.

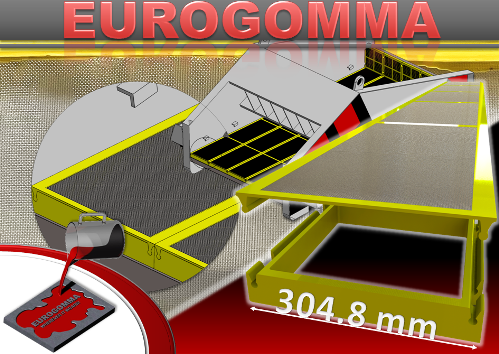

EURO-PS rubber and polyurethane modular screens come in the standard dimensions of 305mm x 305mm and 300mm x 300mm. EUROGOMMA screening modules are available in any thickness, from a minimum of 30mm upwards, and are suitable for gross, medium and fine screening.

EURO-PS polyurethane screens are available with EUROGOMMA’s unique design of “Wavy Top”, “Roll-on”, “SUPA Tough Boy” and with rounded weir bar.

EURO-PS screen panels are supplied together our “lock-out” fasteners, which are characterised by the smart technique of installing and removing the screen panels from the top of the deck.

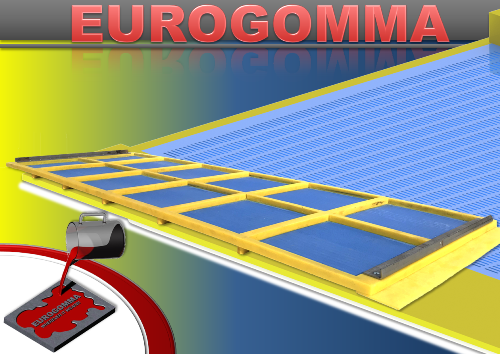

EURO-FG is a screen system made of polyurethane modular screens, polyurethane nocking bars and supporting steel under-construction.

The nocking bars fasten into the steel under-construction and are fastened together with the polyurethane screening or dewatering panels to create the screen deck.

Thanks to the modular concept every standard deck can be equipped with our EURO-FG screen system.

Thanks to the superior quality of EUROGOMMA’s polyurethane materials, the company manufactures long lasting and high performing flip-flow polyurethane screen panels.

Flip-flow screening panels are subjected to continuous stress, which is why the quality of polyurethane is crucial for this application.

EUROGOMMA’s polyurethane screening panels have been successfully installed in equipment that processes coal, coke, compost, wood chips, gravel, hard rock and many more.

Our special screen panels with boomerang and peanut shaped apertures make our products unbeatable versus the competition.

EUROGOMMA red natural rubber sheeting have been installed in several operations to protect machines from wear and abrasion.

The rolls are available in standard sizes of 1.4m x 10m, in thicknesses between 2mm to 50mm.

Smooth, fabric, buffy and, rough finishings are available, to suit various installation requirements.

The high quality of EUROGOMMA red natural rubber sheeting has convinced our clients to choose EUROGOMMA products over other well-established brands.

EUROGOMMA manufactures an extensive range of polyurethane liners and wear parts for mining, sand & gravel, industrial and chemical plants.

Our polyurethane liners are available in these formats:

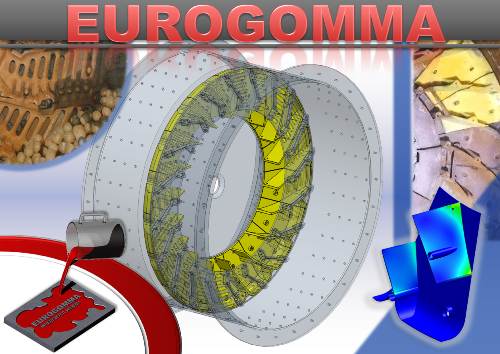

EUROGOMMA manufactures and supplies a large range of polyurethane rotors, stators and dispersers, dart valve components and other related spare parts for froth flotation cells.

The great abrasion and corrosion resistance and the excellent resilience of our SUPERELASTIC Polyurethane permits our parts to last much longer than any competing product in every processing application (gold, copper, phosphate, silica, fluorite…)

Documented tests demonstrate that our Rotors and Stators last between 200% > 300% longer than the original Rubber items.

We have available Polyurethane parts to all the major flotation cells in a range from 66” up to 190”

EUROGOMMA is a group of companies consisting of:

Eurogomma has representatives, distributors and resellers all over the world to serve clients as best as possible.

Almost 50 years of experience in the industrial and mining field, and high-quality products demonstrated and controlled by European Quality Certification UNI EN ISO 9001:2000, means that EUROGOMMA has the necessary capabilities to solve any screening or wear problem with mineral and aggregate processing.

We talk with Eurogomma marketing and sales director Cristian Annoni about the Italian company and its innovative polyurethane screens.

EUROGOMMA supplies polyurethane tensioned screens that offer high-performance and wear-resistance.

EURO-FG is a screen system made of polyurethane modular screens, polyurethane nocking bars and supporting steel under-construction.

SUPERflexy is the screening machine for the hardest material classification. High moisture, sharp and sticky materials are typically creating blinding and clogging problems to standard screening technology like vibrating and trommel screens.

To read about EUROGOMMA's polyurethane trommel screens please download this free whitepaper.

Please download to read this free white paper on polyurethane cutting edge for wheel loaders.

Please download this free whitepaper to read about EUROGOMMA's interchangeable polyurethane liners.

Please download this free white paper to read about EUROGOMMA'S polyurethane sheets with expanded metal mesh.

Please download this free white paper to read about EUROGOMMA'S EURO-PS modular screens.

Bulyanhulu gold mine is an operational underground mine in Tanzania, operated by Twiga Minerals.

The gold operation at Obuasi, 200km north-west of Accra in Ghana, was the major asset of Ashanti Goldfields Company (AGC), established in London in 1897.

The Olympias gold-silver-lead-zinc massive sulphide underground mine is being re-developed in the Halkidiki Peninsula of northern Greece, Europe. The mine is expected to have a mine life of more than 25 years.

Golden Star (Wassa) (GSWL), a subsidiary of Golden Star, owns and operates the Wassa gold mine in south-west Ghana. Golden Star holds a 90% interest in GSWL, while the Ghanaian Government holds the remaining 10% ownership earning a 5% royalty on the gross revenue of GSWL's gold production.

Asanko Gold Mine, situated in Ghana, one of the top ten gold producing countries, is Asanko Gold's flagship project.

Spread across an area of 23,666ha, the Damang Gold mine is located 30km north of Tarkwa in South West Ghana. The mine is owned and operated by Abosso Goldfields (AGL), which is owned by Gold Fields Ghana Holdings (71.1%), IAMGOLD (18.9%) and the Ghanaian Government (10%).

Golden Star Bogoso Prestea (GSBPL) plans to restart the Prestea gold mine, which has been under care and maintenance since 2002, in western Ghana. The gold mine is located approximately 15km south of the Bogoso mine and adjacent to the town of Prestea.

Central Ashanti gold mine is located approximately 57km south-west of Obuasi and 195km north-west of Ghana's capital Accra. It was formerly the Ayanfuri gold project.

The feed chute of grinding mills is a typical wear area in all ore processing plants.

EURO-PS is the most versatile and used screening system of EUROGOMMA.

HERCULES are the 305x305mm polyurethane screen panels for the super heavy impact areas.

The persistence of the Russian-Ukranian conflict and the consequent exclusion of the Russian economical players in the international business have brought us to the decision to relocate the production of some our best sellers to Italy.

We have just presented a newsletter about our EURO-Mic superfine screening panels in February and it is time already to tell about this product again.

EUROGOMMA confirms our deep involvement with the mining sector through the constant development of new products for mineral processing.

The idea is quite simple but very effective. An elastic liner exploits the compression ability of the elastomers joined to their abrasion resistance to fight against the wearing action of materials impacting, flowing and sliding on.

Polishing barrels are very diffused in many industrial processes for the surface finishing of metal products like screws, cutlery, handles, holders, stirrups and of plastic products as well.

We have already said a number of times how Eurogomma is focused on creating customized solutions to all our clients.

Fine screening is a crucial stage of several industrial processes. It is understandable that durable screen cloths with elevated screening performance are a very desirable product in those applications.

Our unique polyurethane elastomer formulation keeps demonstrating to be extremely performing in flotation cells and the end users are very satisfied with the wear life offered.

Our polyurethane cutting edges for wheel loaders are spark free and prevent any risk of flaming.

One of the latest applications is related to the installation of fine wire mesh on screen decks equipped with polyurethane and rubber modular panels.

The applications of our rubber screening products in heavy duties in mining are growing and that is helping us to achieve our production targets in the near future.

Eurogomma's GETflexy solution facilitates the installation and de-installation process of cereal cleaning and separating machines.

Eurogomma manufactures polyurethane modular panels with the insertion of SS wire mesh.

The new year starts with a new product of Eurogomma: flotation dart valves.

November is the month when Eurogomma renews our stocks.

Our trommel screens are tailor-made for every application.

Eurogomma can now produce Superflow apertures of 1mm and under.

Eurogomma has dedicated a specific section of our website to our liners for grain and cereal transportation.

Our polyurethane coating is certified for food processing applications, which allows us to install our finger screens in such applications.

We love when we are called to do something new because that is the philosophy of our group. Now it is the turn of Eurogomma-Russia.

Our ERStep and EURO-PS screen panels are made of rubber.

Endless applications require an endless product range and we are not afraid to afford every request with goodwill and customer care.

Eurogomma applications in polyurethane lined pipes are increasing and our commercial strategies for 2021 are targeting the pipeline protection from abrasion and corrosion in mining plants.

The high-efficiency screening system “Wavy Top” of Eurogomma is now available on ErStep screens.

Our spray-on STB Eurocoating is a wonderful solution to protect truck beds from wear, corrosion, rusting and scratching.

Well, we are not artists but we spray artfully anyway.

EUROGOMMA is the sole world manufacturer of the polyurethane screen panels with rounded weir bar.

Fine screening is a typical application for stainless steel wire meshes. Efficiency is high but the wear life of the screen meshes is a real nightmare.

It was exactly one year ago when we told our followers about our first Superflexy screen in France for the classification of municipal solid waste clinker.

In our philosophy, innovation and customisation are strictly connected because it is thanks to our clients that we can detect which solutions are necessary to create progress in the market.

The range of our PU and TPU screen panels for flip flow installations keeps growing together with our market of these products.

EURO-FG is one of the most diffused polyurethane screening systems in Europe.

Since Eurogomma started the business in 1975, our tensioned screens – in rubber and polyurethane – have always been our best sellers.

Silos are a world-diffused storage system for a number of materials. They are largely used in the food industry to store cereals such as grain, malt, soya beans, hops and others but also for the animal feed.

There is no screening application where Eurogomma can’t propose a customized solution.

The main characteristics of our flip flop screen include high G force, a strong and sturdy structure, and extremely low vibrations.

Eurogomma has been making punched screen cloths for many years.

There is nothing that we love more than innovating. Every problem of our clients is a challenge that we want to win in order to bring something new and something better into the market.

After our successful exhibition at Minex Mount Isa, EUROGOMMA is developing a number of products targeting the Australian market.

It is a fact that EUROGOMMA targets mining as the core market for our elastomer wear-resistant products.

SUPERflexy is quite a new product in the field of flip-flop screens and France is historically affectionate to the German technology in this sense.

In August 2018, we informed our followers about a new unique product of Eurogomma: our ROLL-ON polyurethane screen panels.

Classifying 0>200 micron sand with polyurethane panels is not easy but this is how we do it

EUROGOMMA is happy to propose to our clients in mining the new range of our rubber screen panels for tough applications such as crusher screens and primary ore screening.

EUROGOMMA will take part in one of the most representative mining exhibition in Australia.

Stewart Fernandez and his company, Australian Mining Products and Services Pty Limited, are now representing the Eurogomma group all over the territory of Australia and New Zealand.

The Eurogomma group has reached the important industrial target of starting manufacturing its unique screening system GET flexy at its Russian factory.

Eurogomma is a dynamic manufacturer where new ideas are directly translated into new products, thanks to a flexible CAD/CAM manufacturing system.

Eurogomma’s patented screening system GET flexy has been given another proof of its value at one of the Mirny diamond mines of Alrosa, the world leader in diamond mining.

Rubber self-supporting screen panels are a typical product for primary screening.

EURO-PS wavy top polyurethane screen panels are an invention and unique product of EUROGOMMA.

When we presented GET flexy to our clientele, we did expect a lively interest in the product but we had no idea so many users were in an actual emergency in terms of lack of performance with their screens.

Our boomerang and peanut-shaped apertures have been offering the solution to the problem since 2011 up to now with great satisfaction of us and of the client.

EUROGOMMA and our distributor for the Iranian market, the company Parnian Sanat Atlas have worked at a new project for iron pellet screening in a plant of the biggest steel producer in the Middle East and Northern Africa and the biggest DRI producer in the World.

Flip flow screens have been taking more and more market portions in the last decade and users are typically very happy with the performance offered by this technology.

Another success in gold ore screening in West Africa at Perseus Gold Mining, thanks to our SUPA TOUGH BOY and TOUGH BOY screening panels.

Eurogomma is happy to offer our clientele a new rubber lining product.

As a manufacturer targeting the mining and aggregate fields, it was quite a curious case for Eurogomma to be called into a project to classify live whelk shells.

EUROGOMMA introduces a new polyurethane screen panel with its PURFil screen mesh for gold mining applications.

Eurogomma is happy to present to our friends, clients and followers the new version of its company website, www.eurogomma.com.

Continuing the company's expansion in Russia, Eurogomma is proud to announce the opening of a new production site and stocking warehouse with office facilities in Chelyabinsk, in the Ural region.

Eurogomma is happy to launch the website www.get-flexy.com about one of the most innovative screening media of modern technology.

GET flexy is the patent pending screening technology transforming polyurethane screen deck into a high-efficiency screening technology.

GET flexy is a unique polyurethane screening system, which offers high-efficiency performance in the most difficult applications.

Eurogomma has gained great success in Austria with its flip-flop screening equipment.

After the recent launch of its new high-efficiency polyurethane screening system GET Flexy, Eurogomma is happy to announce a significant installation at its client site, Rockwell Diamonds Inc in South Africa.

Eurogomma's GET Flexy polyurethane elastic screening system can be retrofitted into any existing screen deck to transform it into high-efficiency piece of technology.

Thanks to the superior quality of its polyurethane material, EUROGOMMA manufactures reliable flip-flop polyurethane screen panels.

EUROGOMMA's constant research into improvement of screening performances has led to the creation of GET flexy.

Abrasion, corrosion, impacts and other related wearing forces involve the full mineral processing plant causing several damages and consequently continuous maintenance.

EUROGOMMA manufactures polyurethane modular screen panels available with a multitude of clamping methods.

EUROGOMMA engineers and manufactures customised polyurethane screens fitting all the wear-resistance and screening requirements that customers require worldwide.