High Performance Thickeners AKA-SET: for sludge thickening and valorizing

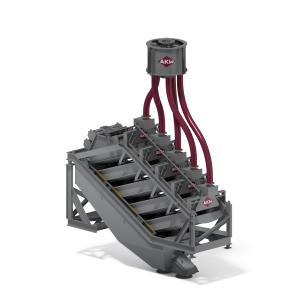

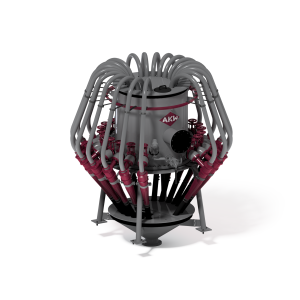

AKA-SET high performance thickeners are used for mainstream process water treatment and slurry thickening. Available as flat or conical versions.

Principle of Operation

The flocculated feed slurry is fed from the top in the center of the thickener tank. Macro flocs will be created in the filtering zone, by having the flocculated feed slurry flowing in counter-current to sedimented particles. These flocs will sediment at a higher speed than the micro flocs of conventional thickeners, resulting in a higher loading rate per unit settling area and smaller thickener diameters.

Design Features and Client Benefits

- High loading rate per unit settling area

- Consistently steady high sludge concentration

- Fully automated • Low energy system

- Produced out of customized or corrosionresistant materials (steel, stainless steel)

- Coating with chemical and corrosion-resistant materials as an option (rubber, polyurethane, ceramic glazed)

- Lifting rake system as an option • Available in conical and flat-bottom versions