Thermal Applications

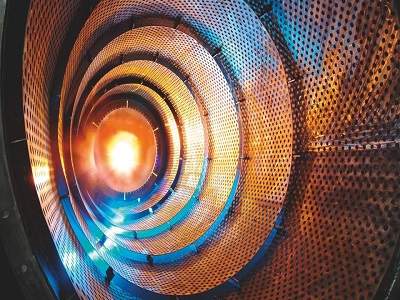

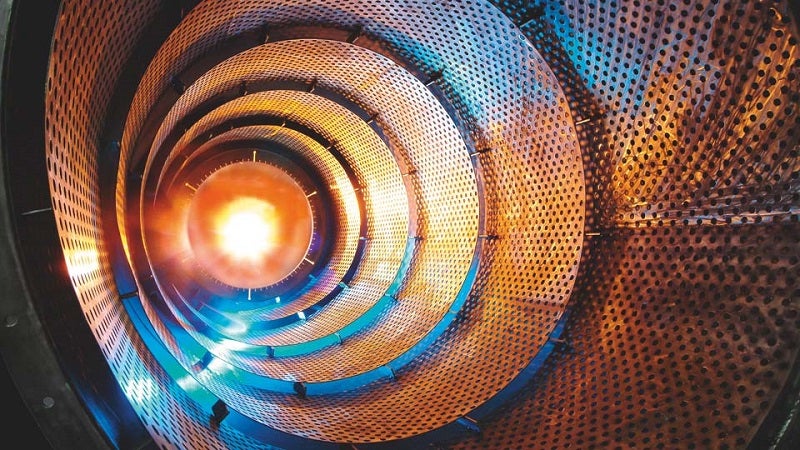

Hot-gas Generator with Steel Combustion Chamber

For the combined drying and grinding process, a heat source is required to dry the grinding stock – this is usually a hot-gas generator. At the beginning of the 1960s, Loesche built the first combustion chamber with no refractory lining. This signaled the start of a success story.

Loesche was and is the only mill manufacturer that can supply all the equipment in-house, namely the mill with its own hot-gas generator.

A milestone

The Loesche combustion chamber, known around the world by the name LOMA heater (LOchMAntel = German for perforated jacket), initiated the age of steel combustion chambers with no refractory linings and is the prototype of all these combustion chambers which are used today worldwide for all kinds of thermal processes.

The first decades in the story of the LOMA® heater were marked by the use of conventional gases and liquid fuels.

Increased energy awareness and the scarcity of pure energy sources gave rise to a high demand for energy-efficient processes and the call for the use of alternative fuels.

The basis for the development of new hot-gas generator systems by Loesche was on the one hand gaseous industrial by-products such as blast furnace gas, coke gas, synthesis gas, etc. and on the other hand the increased use of all manner of solid fuels – from wood dust, through to pulverised lignite and pulverised hard coal, as well as petroleum coke.

We recognize the signs of the times, namely energy efficiency and ecological awareness.