Maccaferri provides innovative engineered solutions for the mining industry, reducing safety risks from rockfalls, reducing erosion due to run-off, stabilising ground and reducing costs of construction for tip and crusher walls.

Wherever problems exist in the lifecycle of a mine, Maccaferri products and solutions can help. From access and materials handling infrastructure, rockfall hazard mitigation, product concentration and leachate storage, to dewatering and site remediation, these solutions are proven to reduce safety risks, reduce construction costs and maintain operations.

Rockfall hazard mitigation in open cast mines

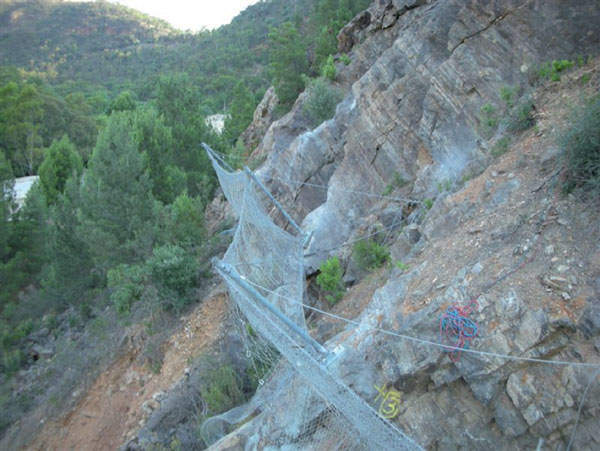

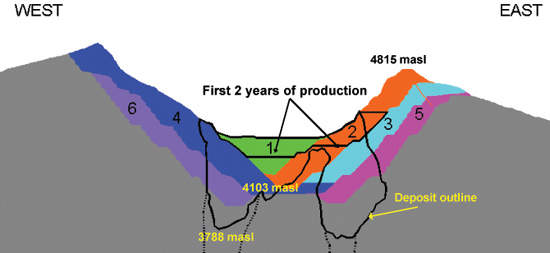

Slopes within open cast mines can be steep to maximise extraction volume and minimise the space for infrastructure. Loose material detaching from these slopes affects mine safety and operations. Maccaferri offers high-tensile steel cable meshes and drapery mesh to contain rocks and provide surface stabilisation. Steelgrid HR is available in tensile strengths greater than 160kN/m, and HEA cable panels for demanding loads up to 200kN/m.

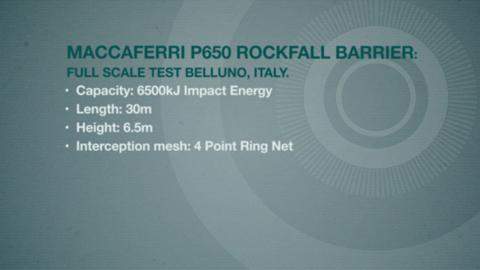

Maccaferri’s range of flexible rockfall protection barriers are available certified by ETAG up to 5,000kJ (MEL) energy absorption. Attached to the rock slope, above critical infrastructure (haul roads, conveyors, tips and crushers), these barriers progressively deform under impact, absorbing loads. Attenuator and hybrid barriers are also available.

Rockfall protection embankments featuring soil reinforced with geogrids, offer up to 20,000kJ energy absorption capacity and can accommodate multiple impacts without maintenance – a significant advantage for cost-conscious mine operators.

Mine access and materials handling infrastructure

Tip and crusher walls constructed from soil which is reinforced with Maccaferri geogrids, produce cost-effective structures. Wherever possible, Maccaferri tries to reuse site-won structural backfill in combination with Paralink and MacGrid geogrids to create reinforced soil structures, reducing costs and material waste.

With geogrid strengths up to 1,600kN/m, even the heaviest vehicles can be accommodated, and many crusher walls of over 20m have been constructed. Maccaferri’s soil reinforcement structures are available with a variety of face-finishes, including:

- Green Terramesh, Paragrid or MacGrid geogrid reinforcement for sloped vegetating faces

- Terramesh soil reinforcement system for gabion faced structures

- MacRES for vertical faced concrete panel walls

Lagoon lining systems, heap leach pads and product concentration

MacLine impermeable membranes waterproof lagoons and heap leach pads, containing concentrates and avoiding infiltration into the natural ground. Combined with MacDrain drainage geocomposites, leachates can be collected efficiently and reliably.

Containment dykes often feature Maccaferri MacGrid reinforced soil, or gabion retaining structures and major dump zones can be supported on basal reinforced platforms. These platforms are reinforced with Paralink or MacTex W2, at the heart of which is polyester reinforcement providing long-term high strength and low strain to minimise differential settlements.

MacTube geotextile tubes are used for dewatering mine tailings, sludge ponds or slurries. Slurry is pumped into the MacTube, which is designed to retain the solid particles while the filtrate fluids are released through the filter fabric of the tube walls. Once drained, the solid residue is left to dry before being disposed of in a controlled manner.

Erosion control and mine remediation

Reinstatement of the mine is vital. Maccaferri offers MacLine impermeable cappings and drainage systems to prevent surface water entering the deposits. MacDrain drainage geocomposites are available with a wide range of filters and core types to provide flow capacity under a variety of load conditions.

The rapid re-establishment of vegetation and soil erosion protection systems completes the closure operations. Maccaferri’s wide range of man-made MacMat and biodegradable BioMac soil stabilisation solutions facilitate this. These mats provide immediate erosion protection from rainfall impact or run-off and long-term root reinforcement.

Shotcrete and roof support in underground mines

Maccaferri’s Pararib tunnel reinforcement mesh contains loose and falling debris from shafts and excavations. Pararib is lightweight, white and flame retardant, making it ideal for use underground.

Wirand fibres are added to shotcrete to reinforce it and provide stabilisation of shafts, excavations and access tunnels and it can even replace traditional steel reinforcement mesh.

Quality mining products and services

Maccaferri aims to build mutually beneficial relationships with clients through the quality of its service and solutions. With nearly 30 manufacturing facilities around the world and more than 60 operating companies in 100 countries worldwide, Maccaferri’s engineers offer technical support, including analysis, design, solution selection and installation supervision.

Please use the form below to contact us, or inquire directly via the Maccaferri websites listed below and the regional offices tab of this company profile.