Interlate® offers proactive solutions to improve decisions, enhance operational productivity, and deliver increased returns to all their stakeholders while driving transformation toward a sustainable future.

We specialise in digital enablement and upskilling, process optimisation, decarbonisation and economic uplift via focused customer engagement.

Automated software platforms for the mining industry

Interlate® minimises time-to-value by focusing on quick wins and building foundations for advanced tech.

Our day-to-day values are influenced by centuries of collective experience in running minerals processing plants.

We assist clients by:

- Overcoming implementation issues and securing value

- Providing data location flexibility

- Taking a longer-term focus towards more challenging operational problems or supporting your team’s digital journey

- Working in real-time

- Upskilling customers by providing relevant software and knowledge

Customised decision-making software

Interlate® can blend the right combination of decision-making software, people enablement and value-driven services to meet your needs.

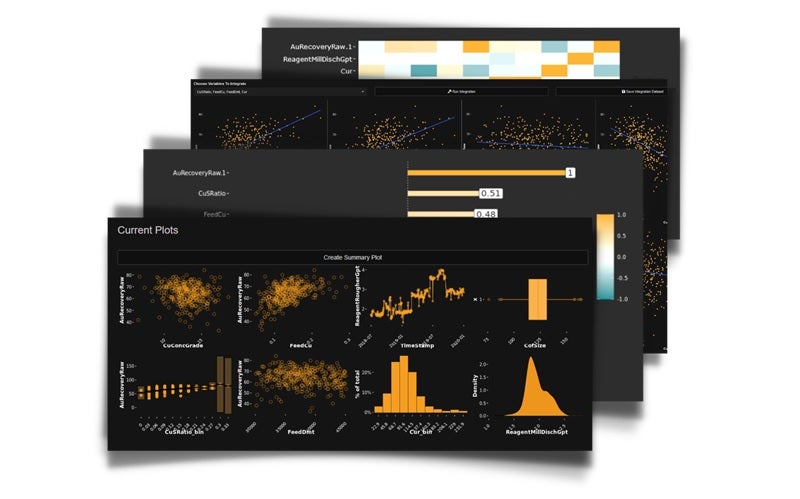

Our standardised analytical workflow gives you a streamlined, integrated experience – spend less time analysing data, and more time implementing value in the plant.

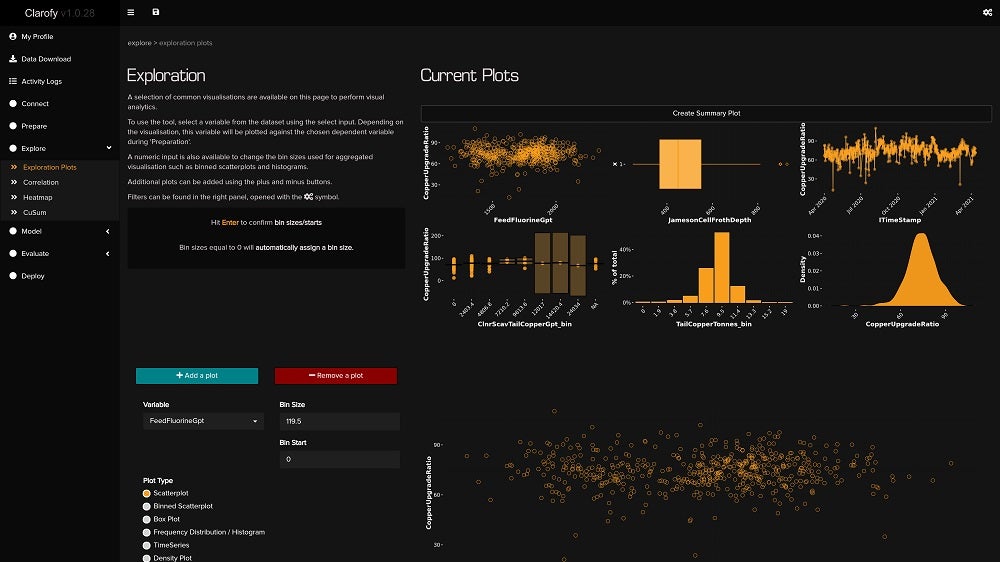

Our solutions enable you to explore plant variables, model and optimise processes, statistically evaluate and deploy outcomes with various output result formats such as flat files, summaries, model files or interface with a control system. A range of deployment options from static to real-time to match your solution and plant needs.

In addition, productivity and / or sustainability deliverables are quantified for easy communication, so you can demonstrate the value of your data and skills with serious value propositions.

Clarofy™ and our application protocol interface (API) are underpinned by our unique API library – a modular, microservices-based minerals processing and data science library with starter, premium and pro modules to help you unlock value immediately.

Suitable for plant process engineers, metallurgists, operational teams, data analysts and data science practitioners, Clarofy™ is our end-to-end minerals processing data science platform that enables users to rapidly explore their plant data and create prescriptive solutions. It also builds predictive process models, evaluate models, and deploy optimised prescriptive outputs for improved process control, as well as create summative reports of your results to share with your teammates, and even save your workflow settings for improved automation.

In addition, the API library is a code-based interface to Clarofy™ that we use to create custom analytical workflows for minerals processing problems and deliver services to our customers every day.

Lightweight and real-time operational services

Interlate® provides a series of services to help optimise productivity levels. Ranging from data analytics to training, our lightweight and real-time operational services aim to enhance remote or on-site operations.

Our services include:

- Data analytics: generates immediately deployable operating tactics from data already available in your operations. Targeted problem solving that is scaled according to specific timeframes or larger, more complex challenges.

- Data architecture: fuse data sources from disparate sources and enterprise systems to improve decision-making at the interfaces along a value chain. It demonstrates the benefit of utilising intelligence from adjacent systems (e.g., Mine Dispatch + Process Historian).

- Benchmarking: understand the opportunities in your process from a standardised analysis of performance and stability to provide strategic insight into a longer-term improvement roadmap and your digital journey.

- Digital Readiness: assessments to help accelerate your journey. Clients can understand the opportunities in their digital assets from a standardised analysis of data-driven decision-making.

- Training: short courses focused on data-driven decision-making for mining professionals, leveraging Interlate’s service expertise. Accelerate digital capabilities and improved decision-making skillsets within your teams.

We also offer a customisable four to six-week package that contains all of the above modules, resulting in a tailored digital accelerator aimed at gaining immediate value-momentum.

Our real-time services comprise fast high-level analytical (HLA) for daily tactical analytics, on-demand. This immediately integrates fast turnaround operating tactics into your technical or operational teams, focused on current operational issues or overflow work.

We also offer our patented Sentinel® real-time analytical and decision support services, consisting of a long-term productivity uplift service focused on both decision support and larger / complex process improvement projects.

Decision automation apps

Interlate® offers a series of apps to help clients automate the decision-making process.

Setpoint Selection explores relationships between plant operating variables at speed. Clients can quickly uncover a data-driven plant operating strategy and review the potential productivity benefit and output for further communication.

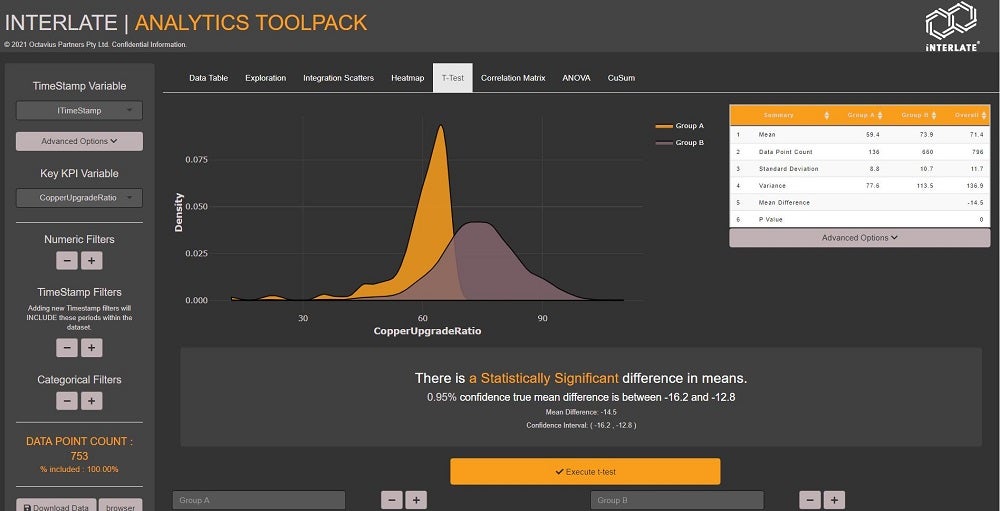

Our Analytical Toolpack app describes and explores plant operating data, as well as quickly performing comparative statistics so clients can experience an expedited iterative process of evaluating and reporting your plant process improvements and trials.

Net Smelter Return Optimisation combines process modelling with optimisation to determine high-level production targets. The app also determines target product grades on parallel minerals processing lines to optimise overall cash flow, as well as dynamically change market assumptions plus feed assumptions for both real-time decision-making or longer-term production planning.