To meet the key target of the 2015 Paris Agreement – limiting the increase in average global temperatures to 1.5°C above pre-industrial levels – the United Nations has repeatedly warned that greenhouse gas emissions must peak before 2025 at the latest, be reduced by 45% by 2030, and reach net zero by 2050.

Construction is a carbon-intensive industry, accounting for at least 40% of emissions on earth, and within that, building tunnelling infrastructure accounts for a significant share. This is driven mostly by the amount of steel and cement used to form the linings and internal structures as well as the diesel to power construction equipment.

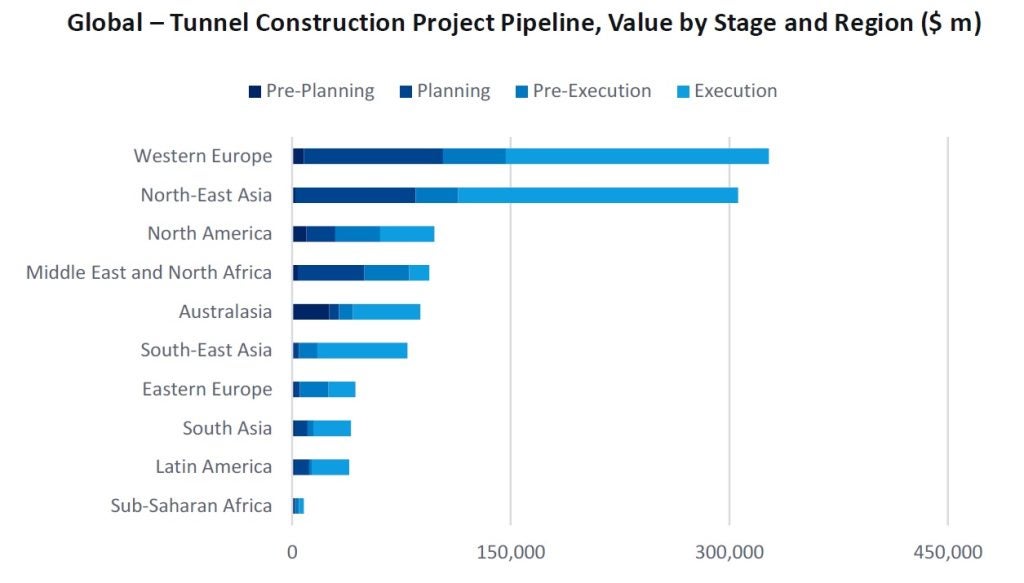

The global tunnel construction projects pipeline, as tracked by GlobalData, stands at $1.12 trillion. Transport infrastructure, which includes the road and rail sectors, dominates the global pipeline of tunnel works, accounting for $1.02 trillion of global project value, a 90% share.

Growing urbanisation means we can expect more tunnels, putting further pressure on the sector to find ways to reduce emissions. There is much talk about sustainability, but action has been limited. Keen to fast-track decarbonisation in tunnelling, Finland-based Normet, a leader in groundbreaking technology and sustainable innovation in underground mining and tunnelling initiated a project to bring together the world’s innovators in green energy.

Two years ago, together with a few founding industry partners, Normet launched an accelerator of sorts along the models typically associated with scaling digital startups.

The SubSpace Energy Hub

Going zero- or low-carbon is no easy task, not least because of the current challenges of transferring and storing energy. As Tom Melbye, former president of Normet, says: “It is not enough that we have electric equipment or sustainable design if we have to use energy that is not sustainable.”

So, is there light at the end of the tunnel? It is hoped that, yes, there absolutely could be – in the form of the SubSpace Energy Hub. Based at the Hagerbach Test Facility (VSH) in a series of caverns and tunnels in the Swiss Alps, the vision is that this initiative will be the guinea pig in finding the best way to store renewable energy, such as wind, solar, geothermal and biogas to power under and above ground spaces.

Decarbonisation plans often involve scaling up new technologies that have inherent risk due to their experimental nature. The SubSpace Energy project aims to be a platform for the harmonised development, prototyping and installation of new technologies that promote best practices in sustainable energy use and storage. Partnering with Hagerbach are a diverse group of companies from the tunnelling, battery technology, mining and green energy sectors: Xerotech, Amberg Group, Alumina Battery Systems, Fortescue Future Industries and Motics.

The initiative provides a blueprint for how infrastructure projects can be designed and constructed with sustainability at their core, accelerating the reality of low-carbon tunnelling.

The SubSpace Energy Hub underscores a collective ambition driven by the goals of the Paris Agreement to push the boundaries of next-generation battery technology. Many of the partners involved in the project seek to advance battery technologies for underground applications, in addition to exploring energy storage solutions.

Melbye, who led the launch of the networking project in 2022, adds: “This is an opportunity for the whole industry to get involved in innovation. That was the idea for putting this network together because one company cannot do it alone. There are a lot of players that play a role here, that is the aim for SubSpace Energy.”

As the climate crisis threat grows, advancing sustainable tunnel construction will be increasingly crucial. The role of companies like Normet, which stands out in its commitment to setting new standards with regard to environmental stewardship will only get more significant.

Among other activities, Normet has an ongoing programme to “considerably” reduce the amount of cement and steel that gets used underground and to replace cement with more environmentally friendly material.

“We are already using 30% to 40% less embodied carbon in the concrete than we were a year ago thanks to our research and we will continue to work towards creating and harmonising best practice guidelines to support the industry in its transition to a green future,” says Ross Dimmock, VP, Tunnelling, Normet.

Discover Normet’s multifaceted low-carbon approach to developing tunnelling infrastructure through project design, Normet SmartDrive® BEV machinery and advanced materials.