Advantages of SONARtrac Flow Meters

Advantages of SONARtrac Flow Meters

CiDRA Minerals Processing provides customers with the ability to convert data to knowledge to action.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

CiDRA Minerals Processing provides customers with the ability to convert data to knowledge to action.

It is our mission to deliver game-changing technologies that provide accurate, real-time data that can be used to optimize industrial processes, maximize recovery, and reduce costs. Our products, systems, and enhanced recovery services provide our customers with new insight into their processes that will allow them to improve their company’s performance.

The CYCLONEtrac™ Particle Size Tracking (PST) system is the only commercial technology capable of providing a highly reliable system for direct, real time measurement of the particle size in the overflow of individual cyclones. This enables real-time closed-circuit grind control strategies targeting improved mineral recovery, plant throughput, as well as for plants to reach their maximum Net Metal Production (NMP).

The PST system was designed with an industry partner to provide operators with actionable information that when properly leveraged can bring sustainable value to their enterprise.

Some key features and benefits of the PST system are:

The CYCLONEtrac PST system comprises junction boxes, SMARTsensors fixed to each individual hydrocyclone overflow pipe, and a control room computer. The sensor provides condition-based monitoring which eliminates the need to manually measure probe wear. The SMARTsensor is wired to the junction boxes located near the hydrocyclone battery, which receives 100V-240V AC power and supplies both 24V DC power and MODbus communications to the sensor assemblies. The junction box also communicates with the CYCLONEtrac computer in the Control Room using industrial ethernet.

The computer is connected to the internet to provide remote monitoring and support from the CiDRA Global Data Center, where technicians monitor and optimize the PST system performance and provide up-to-date information regarding the health of the PST system hardware.

With the CYCLONEtrac PST technology, concentrators around the world have been able to implement an advanced control strategy based on the continuous measurement of the size of the product, making it possible to keep particle size in a variation band as narrow as possible, always complying with the different natural barriers of the process.

Greater stability of the milling process, alone, can bring significant additional benefits in downstream capacity and throughput, but now with the availability of reliable, real-time product size measurements, the process can move closer to process barriers without risking process interruptions or unplanned plant shutdowns.

CiDRA’s patented SONARtrac® sonar technology utilizes array processing techniques to provide two distinct, but synergistic measurements, volumetric flow and entrained air per cent by volume, thereby providing process engineers, metallurgists, and operations personnel with a powerful combination of unique, real-time, value-based tools to reduce process variability and help optimize the process.

The first technique measures volumetric flow rate by monitoring the turbulent ‘eddies’ within the process flow. Passive sonar flow technology provides a direct measurement of the average bulk velocity and provides a full-bore measurement. As with other velocity-based flow meters, knowing the inner diameter of the pipe, the volumetric flow is derived.

The second technique measures the speed at which sound propagates through the fluid to provide compositional information. The sound speed measurement made by the passive sonar meter is also a real-time, direct measurement from which the gas void fraction (entrained air per cent by volume) measurement is derived. Both the volumetric flow and entrained air measurements can be provided as separate outputs to the DCS. The entrained air measurement is particularly synergistic with the SONARtrac volumetric flow meter in that the measured sound speed can be used to determine the volumetric fraction of the two-component mixture, whereby the total volume of the flow can be adjusted to a ‘true’ flow measurement of the slurry or liquid flow.

Passive sonar technology is the solution for a more accurate, reliable, and repeatable measurement of volumetric flow than any other option on the market, with zero maintenance requirements. Because the passive sonar flow meters do not contact the process media, they have extremely long lives. SONARtrac meters have been in service since 2003 and require zero maintenance and need no recalibration. In addition, novel performance gains can be achieved by utilizing the entrained air measurement for nuclear density measurement correction, monitoring and highlighting process disruptions to take corrective actions that lead to recovery improvements based on a more uniform particle size distribution feed to flotation.

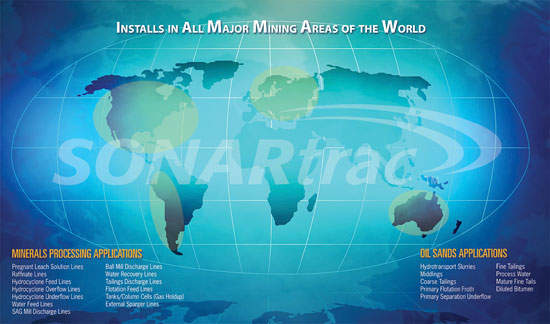

CiDRA Minerals Processing is a trusted partner of major mining companies and operates in more than 400 mining operations in more than 45 countries across the globe. The safety of our internal and external stakeholders together with meeting our customers’ unserved needs are the main driver for CiDRA’s passion for innovation and ingenuity and what has led us to develop industry-specific product optimization solutions. CiDRA provides step-change technologies that enable customers to convert real-time process measurements into actionable information and knowledge.

Being a private company has allowed CiDRA to maintain its investment levels in R&D and technologies that drive recovery, reliability, and sustainability initiatives, even when the mining industry and economy is in a downturn and maintains its 4,180m² research and manufacturing facilities for over 25 years.

From CYCLONEtrac™ grind management technology, which provides real-time, on-line, particle size measurements at the individual cyclone level, to its SONARtrac® process technology for flow and entrained air measurements, CiDRA patented technologies are recognized as an industry leader.

World-class process optimization technology together with world class support you can rely on. CiDRA has your back.

Advantages of SONARtrac Flow Meters

CiDRA Minerals Processing has developed a novel and robust technology that provides a highly reliable and low maintenance system for online measurement of the particle size in the overflow of individual cyclones.

The ability of the sonar technology to passively measure flows from the outside of the pipe, enables unprecedented measurement performance and reliability in highly aggressive slurries and fluids.

Transforming data to knowledge to actionable decisions.

The Morenci copper mine is expected to continue mining activities until 2041.

The Escondida copper-gold-silver mine is located in the Atacama Desert, Chile.

The Boddington gold mine (BGM) employed autonomous haul trucks in 2021 to enhance productivity and safety.

Rio Tinto’s Kennecott copper mine in Utah plans to use renewable energy sources to power its operations.

Collahuasi copper mine is situated in northern Chile, about 180km southeast of the port of Iquique, at an altitude of 4,000m.

With an ore body 4km-long, 80m-thick and reaching a depth of 2km, LKAB’s Kiruna is the world’s largest, most modern underground iron ore mine located in northern Sweden.

Mount Isa Mines (Xstrata 100%) operates two separate mining and processing streams, copper and zinc-lead-silver. Mount I

Carajás Mine, the world's largest iron ore mine, is located in the state of Para in Northern Brazil. Fully owned by Brazilian miner Vale (CVRD), it holds 7.2 billion metric tonnes of iron ore in proven and probable reserves.

Canadian mining company Goldcorp is expanding its Peñasquito open-pit polymetallic mine project in the north-eastern corner of the state of Zacatecas, Mexico.

The Prominent Hill gold and copper mine is 650km north-west of the South Australian capital Adelaide, 130km north-west of BHP Billiton's Olympic Dam and 130km south-east of the town of Coober Pedy in the Gawler Craton of South Australia.

The Weir Group PLC (“Weir”), a leading engineering and mining technology company and CiDRA Minerals Processing Inc. (“CiDRA”), a leader in mineral processing technologies, announce that they have signed a global collaboration agreement alongside a strategic investment by Weir in CiDRA’s mining business.

CiDRA Minerals Processing Inc. is proud to announce its participation in the MINEXCHANGE 2024 SME Annual Conference & Expo, taking place from February 25 to February 28 at the Phoenix Convention Center.

At the same time, CiDRA and OZ Minerals have agreed to deploy a demonstration plant based on CiDRA’s technology at the site.

Second generation CYCLONEtrac™ particle size measurement and tracking system now includes a suite of new capabilities.

CiDRA Minerals Processing has engaged Koch Project Solutions (Koch) to provide front-end engineering and design and project execution management services for the commercial scale-up and global deployment of CiDRA’s novel mineral separation systems.

CiDRA announced that it has entered a channel partner agreement with iKontrol, based in Izmir, Turkey.

CiDRA has announced the results of a 12-year calibration test performed at Alden Research Laboratory, a National Institute of Standards and Technology (NIST) traceable and certified facility located in Massachusetts.

CiDRA announces today the successful completion of another project win with KROHNE Australia for CiDRA's SONARtrac® flow measurement solution.

CiDRA Minerals Processing Inc. today announced the successful deployment of its SONARtrac flow technology in OceanaGold's Didipio gold mine in the Philippines.

CiDRA Minerals Processing Inc. today announced the successful deployment of the company's SONARtrac flow technology in OceanaGold's Didipio gold mine in the Philippines.

CiDRA Minerals Processing Inc. announces the CYCLONEtracSM classification optimisation family of products, which are novel, complete turnkey systems that enable reliable optimisation of classification at the individual hydrocyclone level.

CiDRA Oilsands has announced that a significant milestone has been met with the successful commissioning of over 1,000 HALO® pipe wear measurement and characterization systems.

CiDRA Minerals Processing Inc. announced today the successful installation of the largest SONARtrac system in Peru, the largest flowmeter in Peruvian mining.

CiDRA Oilsands announced an agreement with Expro Meters that will allow the Companies to partner in the sales of both passive and active sonar flow systems and services.

CiDRA announced that it has entered into a strategic sales representative agreement with KROHNE Australia Pty Ltd. Under the terms of the agreement, KROHNE will act as a sales representative of CiDRA's SONARtrac array-based flow monitoring systems in Asia and the Pacific, outside of Japan.

CiDRA Minerals Processing Inc. ("CiDRA") announced that it has entered into a strategic sales representative agreement with Classic Controls Inc. based in Lakeland, Florida. Under the terms of the agreement, Classic Controls will act as an exclusive sales representative of CiDRA's array-based flow monitoring systems for minerals processing applications in Florida and South Georgia.

CiDRA Minerals Processing Inc. ("CiDRA") announced that it has entered into a strategic sales representative agreement with ATSCO Sales & Service, Utah.

CiDRA Minerals Processing Inc. announced the successful commissioning of the SONARtrac system on a dewatering line 302m underground.

CiDRA today announced that it has received Class 1 Div 2 certification for the Company's HALO SMARTring System.

CiDRA Oilsands announced today that the largest known full-bore, non-contact flowmeter in the mineable oilsands industry was successfully installed by CiDRA.

CiDRA Minerals Processing Inc. announced today that Southern Copper Company's Cuajone mine in Peru has awarded CiDRA a contract to supply, install, start-up and commission a 48" diameter SONARtrac flowmeter, the largest to be installed in Peru.

CiDRA's vice president and chief strategy officer, Dr. Alan D. Kersey, was invited to speak at the SPIE sponsored House of Representatives Research and Development Caucus, on 17 April 2012, with a case study on 'enabling innovation in sensor technology'.

CiDRA Oilsands has announced the creation of a new business unit to manage the growth and expansion of services in the areas of asset integrity and management.

CiDRA Oilsands announced today that Canadian Dewatering L.P (CDLP) has chosen CiDRA's SONARtrac® flow monitoring systems for several key applications managed by CDLP.

CiDRA Minerals Processing has announced that Altos Hornos de Mexico, S.A. de C.V. (AHMSA) has chosen CiDRA's SONARtrac® flow monitoring systems as their preferred technology for use in two coal preparation plants owned by AHMSA, located in Coahuila, Mexico.

CiDRA Minerals Processing has announced that Anglo American has awarded CiDRA a contract to supply SONARtrac process monitoring systems to the Los Bronces Development Project.

CiDRA Minerals Processing has announced that Rio Tinto has chosen CiDRA's SONARtrac® flow monitoring systems as its preferred technology for use on slurry lines at Oyu Tolgoi in Mongolia.

Industrial gearbox specialist Hansen Industrial Transmissions (HIT), formerly in hands of Hansen Transmissions International (HTI), and acquired by Sumitomo Heavy Industries (SHI) in March 2011, is ready to move forward under its new ownership. In combination with its extended product portfolio f

Industrial gearbox specialist Hansen Industrial Transmissions (HIT), formerly in hands of Hansen Transmissions International (HTI), and acquired by Sumitomo Heavy Industries (SHI) in March 2011, is ready to move forward under its new ownership. In combination with its extended product portfolio f

CiDRA Minerals Processing, working together with KROHNE in China and Australia, has secured a major project win at CITIC Pacific Mining's Sino Iron Project in Australia. The massive Sino Iron project is being developed at Cape Preston, 100km south-west of Karratha in Western Australia's Pilbara r

Hansen Transmissions International has announced that the notice to the Special Shareholders' Meeting, to be held on 24 June 2010 in Edegem, Belgium, has been published today and is now available on the Hansen website. Copies of the notice, together with the proxy form, have been subm

Hansen Transmissions International NV ("Hansen", "the Group" or "the Company", LSE ticker 'HSN') has announced its results for the three months ending 31 March 2010 and for the 12 months ending 31 March 2010. Highlights of the 2010 financial year include: Revenue decl

Hansen Transmissions International, an established global wind turbine gearbox and industrial gearbox designer, manufacturer and supplier, with a leading position (by MW supplied) in the wind turbine gearbox market, will publish its results for the three months ended 31 March 2010 and for the f

The board of Hansen Transmissions International is pleased to announce, with effect from 31 March 2010, the appointment of Alex De Ryck as chief executive officer (CEO) following the decision by Ivan Brems to retire from active executive duties as CEO of the company. Alex De Ryck curr

DRA is currently designing a 400tph coal washing facility for Total Coal South Africa's Dorstfontein project in Kriel. The project will include an export stockpile and withdrawal facility as well as a rail load-out terminal. Interestingly, the Dorstfontein project will be the division's largest p

CiDRA Minerals Processing announced today that SONARtrac process monitoring instrumentation has been chosen for flow measurement on critical water lines within the Collahuasi mine in Chile. CiDRA, working with TIAR Ltda of Chile, has installed more than ten systems in the mine's concentrator wate

In a new approach to tackling the skills shortage, Murray & Roberts Cementation is investing in increased capacity at its training centre to allow for greater numbers of students as well as exposure to the true mine environment. Full scale mock ups of shafts, tunneling and production areas, w

Mock-ups and computer-aided training to enhance productivity and ensure safety Additional shaft mock-ups, a multimedia education centre, and two new mining equipment simulators are planned for the Murray & Roberts Cementation Training Academy at its premises in Bentley Park near the

Aquarius Platinum’s Marikana Platinum Mine has extended its trial mining contract, originally awarded in 2005, with Murray & Roberts Cementation at its No 1 Shaft and newly planned No 2 Shaft. The estimated annual revenue from the project is R45 million and the project will, at steady state,

Murray & Roberts Cementation recently completed the contract to construct two water retaining bulkhead plugs underground on 27 Level at Kloof No 10 shaft. A remarkable aspect of the contract was the fact that two teams of women not only operated the batch plant, but were directly i

Ventilation underground is a critical constituent of mining, and the construction of a new ventilation shaft can be extremely complex. Murray & Roberts Cementation is completing a massive ventilation shaft installation project for Aquarius Platinum. The entire project consists of t

The successful construction of a four-pump grout plant at Anglo Platinum Ltd's RPM Union Section by Murray & Roberts Cementation will meet the ongoing support needs for production on the mine's decline section. Murray & Roberts Cementation was awarded the contract in January 20

The VF-50 flow meter uses CiDRA’s proven sonar technology to provide accurate and reliable flow measurements.

SONARtrac PFM delivers both top and bottom line value for thousands of customers around the world.

The technology's value lies in its ability to track the particle size of the entire overflow stream from a hydrocyclone battery based on the contribution from each individual hydrocyclone.

Data is provided in real-time to the control room to allow operators or a control system to take corrective action to prevent adverse impacts on the downstream process.