Minegrid®

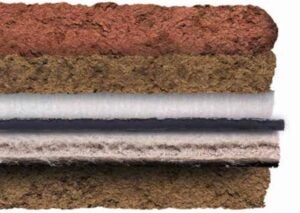

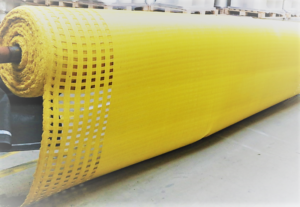

With more than 25 years of experience, Minegrid has been used in mines around the world. It has proven itself in the most extreme conditions. Minegrid is manufactured and woven under tension from high-tenacity synthetic materials such as polyester [PET] and polyvinyl alcohol [PVA]. Our highly sophisticated Minegrid is coated with a flame-resistant, anti-static coating, which meets all the requirements of the Mine Safety and Health Administration. Minegrid has an unequalled safety record, and mines and quarries depend on Minegrid to enhance safety, production, and profitability in their operations.

Improved ground control

Minegrid picks up the load quickly, keeps the mine roof tighter, minimizes cribbing, and maximizes the work area. The geogrid is non-conductive, fire retardant, and coated for high visibility. Minegrid is more workable and conforms to irregularities more easily than metallic mesh and is much less likely to cause injury to workers.

Thanks to a wide range of sizes Minegrid is the solution for a wide range of applications in the mining sector:

- Longwall recovery/relocation

- Mine roof/back support

- Mine rib support

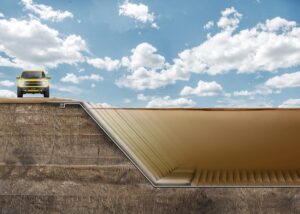

- Highwall control

Minegrid is especially characterised by its flexibility and ease of installation. Over 900 longwall recoveries worldwide have been made safer, faster and less costly. HUESKER’s Minegrid is a replacement for welded wire mesh.

Benefits of Minegrid

- Safe long-term support with negligible deformation

- Long service life

- High visibility coating

- FRAS rating meets all requirements of Mine Safety and Health Administration (MSHA)

- Recovery systems are assembled in one piece to meet mine specifications

- Up to 30-year service life

- No sharp ends to cause injuries