Improving Plant Productivity with Automation Asset Performance Management (APM)

As businesses strive to improve the bottom line and gain a competitive advantage, improving operational efficiency is one of the key objectives for manufacturing plants.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Schneider Electric helps maximize mining stakeholders return and build a sustainable business that is responsible, efficient and profitable with integrated automation, power and process digital environment along a unified value chain.

Mining market faces a “make or break” moment on the industry impacted by trends such as sustainability, market volatility, shorten investment cycles, or workforce shift. How mining adapts, operationalizes and integrates those elements will define successful mining companies in the next years. It is a technological transformation but also a cultural one as these companies evolve to cleaner, decarbonized and integrated value chain practices.

Schneider Electric empowers our mining customers to maximize shareholders and community return by making data-driven decisions in a volatile business, to maximize operational excellence and energy efficiency, optimize production and value chain performance throughout the entire project lifecycle.

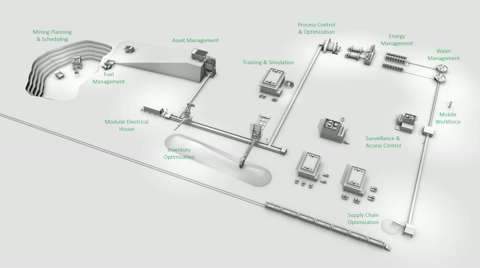

Our solutions are built on EcoStruxure, our IoT ready platform, which integrates different domains of expertise (automation, power, building, IT) in a seamless architecture and transform information collected from anywhere into actionable wisdom for optimized and paperless end-to-end operations.

Together with Schneider Strategic Partner AVEVA, EcoStruxure for Mining creates integrated digital environments and redefines energy journey leveraging integrated power, process and automation to enable enterprise digital transformation and to install a culture of innovation for sustainable business. Global companies like Roy Hill, Tuprag, ArcelorMittal or Saint Gobain trust Schneider Electric to optimize every step towards this transformation.

Our customers work with us because we help them to:

As businesses strive to improve the bottom line and gain a competitive advantage, improving operational efficiency is one of the key objectives for manufacturing plants.

Holistic modernization goes far beyond upgrading by identifying and implementing new sources of automation‑enabled, sustainable business value.

Discover the benefits of microgrids and their applications with some example projects

This paper examines the benefits of various strategies for electrical distribution equipment maintenance.

Roy Hill iron ore project is located in the Pilbara region of Australia. The mine is part of the Chichester Range in Western Australia and is the biggest undeveloped Marra Mamba deposit in the region.

An Integrated Operations Management (IOM) strategy can contribute to the three major competitive imperatives that enable a sustainable and profitable business in these industries.

Assessing digital transformation benefits.

Schneider Electric is to hold an Innovation Talk Webinar titled 'Digital Solutions for Efficiency and Productivity in Mining, Metals, & Minerals'.

Schneider Electric, the leader in digital transformation of energy management and automation, and AVEVA, the global leader in engineering and industrial software, has announced their expanded partnership to deliver innovative solutions for the data center market.

Schneider Electric, the leader in the digital transformation of energy management and automation, will hold its annual Global ALLIANCE Partners conference on June 25-27 in Cannes, France.

PowerLogic ION9000 is the newest ‘connected product’ addition to IoT-enabled EcoStruxure™ Power architecture.

Schneider Electric, the leader in digital transformation of energy management and automation, today announced the availability of EcoStruxure™ Asset Advisor for electrical distribution and critical data center assets as part of the company’s EcoStruxure IoT-enabled system architecture and platform.

Schneider Electric, the leader in digital transformation of energy management and automation, today announced several new solutions to reinforce its EcoStruxure Power digital architecture for energy management and deliver enhanced value to professionals in the power industry, including contractors, consulting engineers, panel builders, system integrators and their end customers.

Schneider Electric, the leader in digital transformation of energy management and automation, has introduced the Modicon M580 Safety Controller, an Industrial Internet of Things-enabled safety and process controller that drives new levels of safety and operational profitability.

The Industrial Software Platform delivers maximum return on capital investment and profitability across the asset and operations lifecycle.

Partnership integrates Cylance’s AI-powered cyber defense within the Industrial Software Portfolio.

India-based software delivery centre (SDC) appraised at Level 5 of the CMMI Institute’s Capability Maturity Model Integration (CMMI).

Schneider Electric, the leader in digital transformation of energy management and automation, launched a new service that will help industrial manufacturers modernise their programmable logic control (PLC) systems easily, safely and more cost-effectively, sometimes in less than one hour.

Schneider Electric has announced enhancements to its Manufacturing Operations Management (MOM) solution for the mining industry.

Schneider Electric, the global specialist in energy management and automation, announces EcoStruxure™ for Mining, Minerals and Metals, a new system architecture that leverages innovative digital technologies and the IIoT to allow companies to seamlessly connect, collect, analyse and act on data in real time to improve safety, efficiency, reliability and sustainability.

Schneider Electric's process control and automation products provide mine sites with greater control of their operations and improved safety.

Mine sites are often in remote locations, or across a series of disconnected satellite locations, so hauling and transporting materials requires detailed planning.

Mining is a complex industry. Extracting raw material in different shapes, sizes and chemistries from the earth's crust and transforming it into a standardised and high-quality final product is a challenging process, not to mention that it involves huge material movement, scheduling, synchronisation and tracking.

Providing Europe's largest gold mine with an efficient, safe and reliable electrical system.

See the full portfolio of our solutions in a 3D virtual flyover of a typical open pit mining operation.

Building an integrated operating model for end-to-end visibility of their enter value chain, from pit to port, for a 55Mtpa iron ore mining business.

Get up and running fast and reduce risk with Schneider Electric's packaged mine solution - the out of the box answer for electrical distribution, process automation, energy efficiency, data management, and access control.

Underground fan exhaust application using the Altivar Process variable speed drive from Schneider Electric.