Automatic Lubrication Systems

Efficient lubrication is paramount for machine reliability, as improper lubrication can result in heightened downtime, escalated expenses, and an uptick in safety incidents. They help to:

- Continuously lubricate while the machine is operational to enhance efficiency

- Minimise friction and wear, thereby optimising bearing and machinery lifespan

- Decrease machine downtime and prolong component longevity

- Lubricate during bearing rotation to enhance lubricant dispersion

- Monitor the lubrication process to notify operators of potential machine failures, enabling preemptive action

Automatic Lubrication Solutions for the Mining Industry

Machine lubrication significantly impacts maintenance budgets, with direct costs constituting merely 1-3% of the total, while 40% of maintenance expenses are attributed to inadequate lubrication practices, often resulting in increased downtime, elevated costs, and safety incidents.

Regardless of your lubrication protocol, machine variety, or sector, we are committed to collaborating with you to identify the optimal automatic lubrication system that precisely meets your requirements.

Our bespoke solutions can assist you in attaining your performance objectives, be it maximising uptime, reducing maintenance costs, or optimising energy consumption:

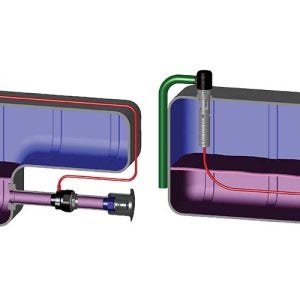

Single-Line Lubrication Systems

Ideal for small-to-medium line lengths and various lubricants

Comprising a central pump station, these systems automatically deliver lubricant through a single supply line to the injectors. Each injector is assigned to a specific lubrication point and can be finely tuned to dispense the precise amount of grease or oil required. These systems can cater to a single machine, different zones on one machine, or multiple separate machines.

- Straightforward, dependable, and suitable for a wide range of lubricants

- Integrated system control and monitoring

- Pump functionality over extensive distances and across a broad temperature spectrum

- Injectors available in preset and adjustable models for standard or customised metering

- Continuous system operation even if one point becomes obstructed

- Effortless system expansion

- Systems compatible with grease up to NLGI 2 oil and fluid grease

Progressive Lubrication Systems

Designed for small to mid-sized machines requiring uninterrupted lubrication

Progressive lubrication systems utilise a pump linked to primary metering devices to ensure a steady flow of lubrication. Additional secondary metering devices can be incorporated to extend the coverage to more lubrication points, with predefined quantities of lubricant evenly distributed.

Ideal for small- to medium-sized machines necessitating continuous lubrication, this system dispenses precise, metered lubricant to up to 150 points, spanning distances of approximately 15 metres.

- Continuous lubrication providing frequent and precise amounts of lubricant to each lubrication point

- Integrated, user-friendly, and cost-effective system monitoring with straightforward blockage control

- Effective performance in harsh conditions and operational in temperatures ranging from -40 to 70°C

- Progressive systems compatible with oil and grease up to NLGI 2

- Serving 150 lubrication points, with a maximum reach of 15 metres for grease systems and 100 metres for oil systems

High Chief Pump

The JSG High Chief Hydraulic grease pump has been proudly manufactured in Australia by JSG Industrial Systems for the past 25 years. It has consistently proven to be a top-quality and high-performance leader in hydraulic grease pumps, catering to various types of automatic lubrication systems. Additionally, it can be adapted for grease transfer applications.

Features & Benefits:

- Adjustable outputs suitable for single-line parallel injector systems, single-line progressive systems, and two-line systems

- Equipped with a shovel foot pump tube for efficiently pumping non-self-leveling lubricant

- Utilizes a complete pump design featuring unitised construction, integrated valving, and solid-state circuitry, enabling on/off control via a 24VDC supply

- Tamper resistance ensured, as the reciprocating rate can only be altered by the optional programmer; once set and the programmer removed, the rate remains unchanged

- No additional system controls necessary to operate the pump when using the cycle timer version; otherwise, the JSG G2 lubrication controller with a second output signal can be utilised

- Modular construction facilitates easy and cost-effective maintenance

- Designed to transfer NLGI2 grease at a rate of 132cm2/minute, contingent on the pump setting and system design

- Detailed High Chief Pump manual readily available for seamless installation and servicing

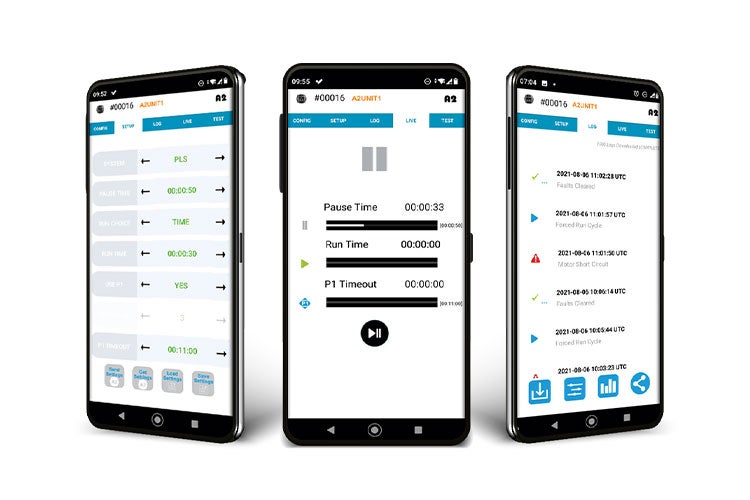

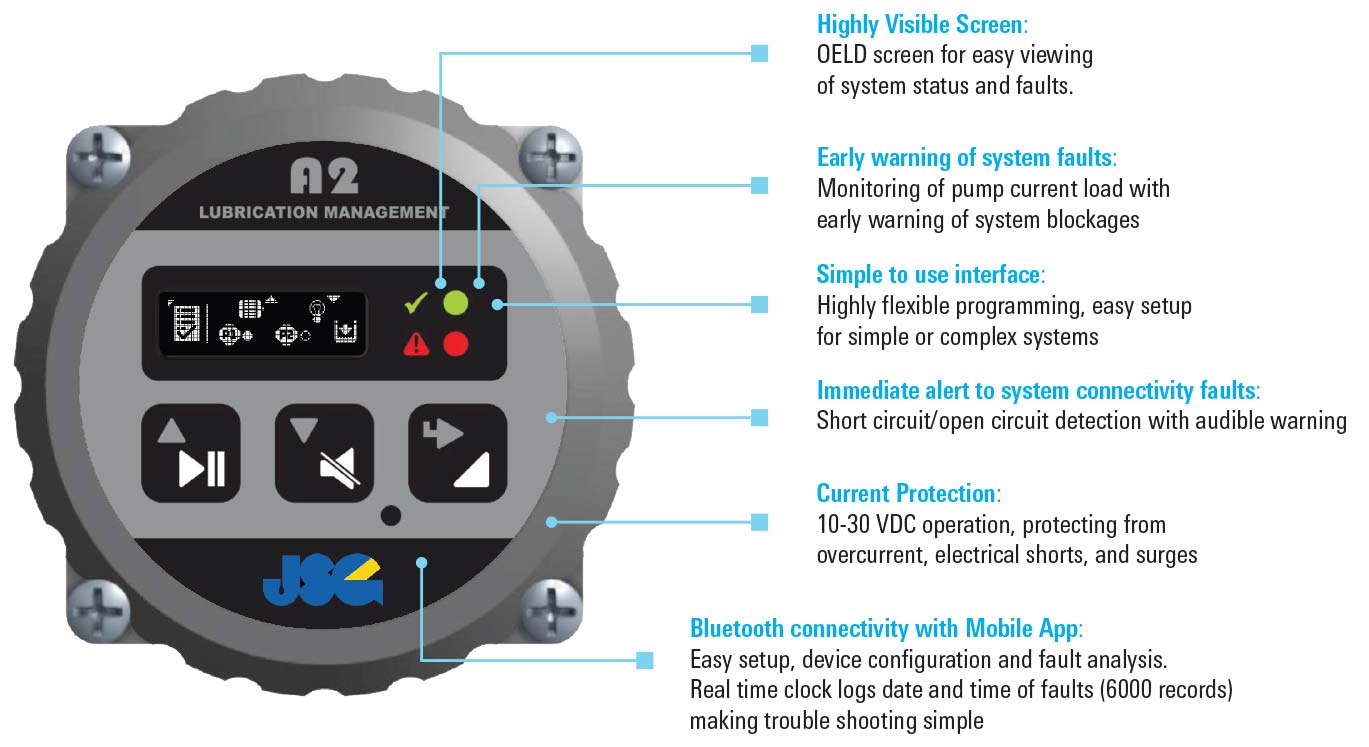

A2 Smart Controller & Autolube App

The latest advancement in smart controllers for lubrication system oversight.

The A2 smart controller represents the forefront of lube management for progressive and single-line lubrication systems. It integrates an IoT solution for overseeing and monitoring the lubrication of critical capital assets, offering a modernized approach capable of managing various system types.

Accessing the controller interface no longer requires accessing the control panel directly. When coupled with the mobile Autolube app, users gain full system control. Utilizing Bluetooth connectivity enables localized remote management.

- Capable of managing various system types for enhanced flexibility

- Access to controller interface without direct control panel access

- Localized remote management facilitated through Bluetooth connectivity

A2 Autolube App Bluetooth & Remote Connection

- Complete control of the automatic lubrication system

- Improve commissioning, testing and troubleshooting

- Easily view and change settings making setup simple

- View the live status of the A2 controller

- Easily view, download and share logs