Mako Project Processing

The Mako Fold Project is located in south-eastern Senegal in the Kedougou region, close to the Gambia River and township of Mako.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Orway Mineral Consultants (OMC) specialise in all aspects of crushing and grinding modelling, site circuit optimisation, and provide hydrometallurgical expertise. The Australia and Canada-based consultancy is a world leader in comminution, providing a range of services to the mineral processing community. With a primary focus on grinding applications, OMC was instrumental in the wide acceptance of SAG milling in the mining industry.

OMC provides crushing and grinding circuit selections and major equipment sizing services for both greenfield and expansion projects. By interpreting rock breakage comminution testwork data and modelling, OMC can determine the most efficient crushing and grinding circuit configuration for all ore types:

Work is undertaken as part of engineering scoping/pre-feasibility, definitive feasibility studies or detailed design which includes:

OMC provide exclusive mill sizing services to Outotec.

OMC undertake many grinding circuit optimisations worldwide, providing clients with significant cost savings and increased production levels often requiring no capital input.

Comminution circuit optimisations typically involve circuit audits and collection of circuit data. This includes major equipment sizes and operating conditions. Mass flows, particle size distributions and densities for each stream are collected along with samples for ore characterisation testwork.

Considerable improvements in plant performance are often obtained through recommended changes to control philosophies and training based on preliminary audit results.

Survey data is model fitted using a combination of OMC power based and JKSimMet modelling techniques. Simulations are undertaken to assess influences of varying process parameters on circuit performance. Recommendations are made based upon analysis of data and specific problem areas are identified. These typically include changes to:

Expertise is provided across a wide range of commodities including gold, copper, nickel, iron ore, uranium, manganese, lead/zinc and mineral sands.

OMC has fostered a highly skilled team specialising in the field of hydrometallurgy. OMC understand issues in complex hydrometallurgical processing with expertise in a wide range of commodities including: uranium, nickel, copper, cobalt, platinum group metals, gold and safe disposal of metalloids that co-exist.

Services include:

Nickel / Cobalt – OMC has experience in leaching nickel and cobalt from both lateritic and sulphide deposits via atmospheric, pressure oxidation or metathesis process. Leach products can be taken through purification using solvent extraction, precipitation or ion exchange process to crude and pure semi-products, or refined to metals (divided cells for example).

Copper – OMC has experience in leaching copper from low and high grade oxide deposits via heap leaching and tank leaching, sulphide concentrate leaching via low and high temperature pressure oxidation process as well as SXEW or direct EW. OMC are involved in producing super concentrates via concomitant removal of uranium, cobalt, arsenic and other deleterious elements from copper sulphide concentrates.

Platinum Group Metals (PGM) – OMC has design and operating experience in refining, to 4N purity, of platinum group metals and gold. Feed sources are typically concentrates from mattes and secondary feed stocks (e.g. spent autocatalysts).

Processes include classical chloride systems and newer technologies incorporating substituted quaternary ammonia salts (SQAS).

OMC can design to NIOSH/ACGIH air quality standards.

Uranium – Design and operating experience with calcrete, sandstone, granitic and sulphide hosted deposits across the globe. We routinely scope and supervise testwork programs, as well as pilot plant trials, using acid or alkali leaching methods followed by solvent extraction or ion exchange concentration.

OMC assists the International Atomic Energy Agency (IAEA).

Flotation

OMC has expertise in base metal and refractory gold ore flotation. Techniques include bulk, differential and collective/selective methods at laboratory, pilot plant and conventional full scale.

Gold metallurgy

OMC has strong gold processing expertise and can provide assistance in all aspects of gold processing including:

For more information, please contact OMC.

The Mako Fold Project is located in south-eastern Senegal in the Kedougou region, close to the Gambia River and township of Mako.

The Mount Carlton project in Queensland's North East sits on a high-sulphidation epithermal style deposit rich in gold, copper, and silver.

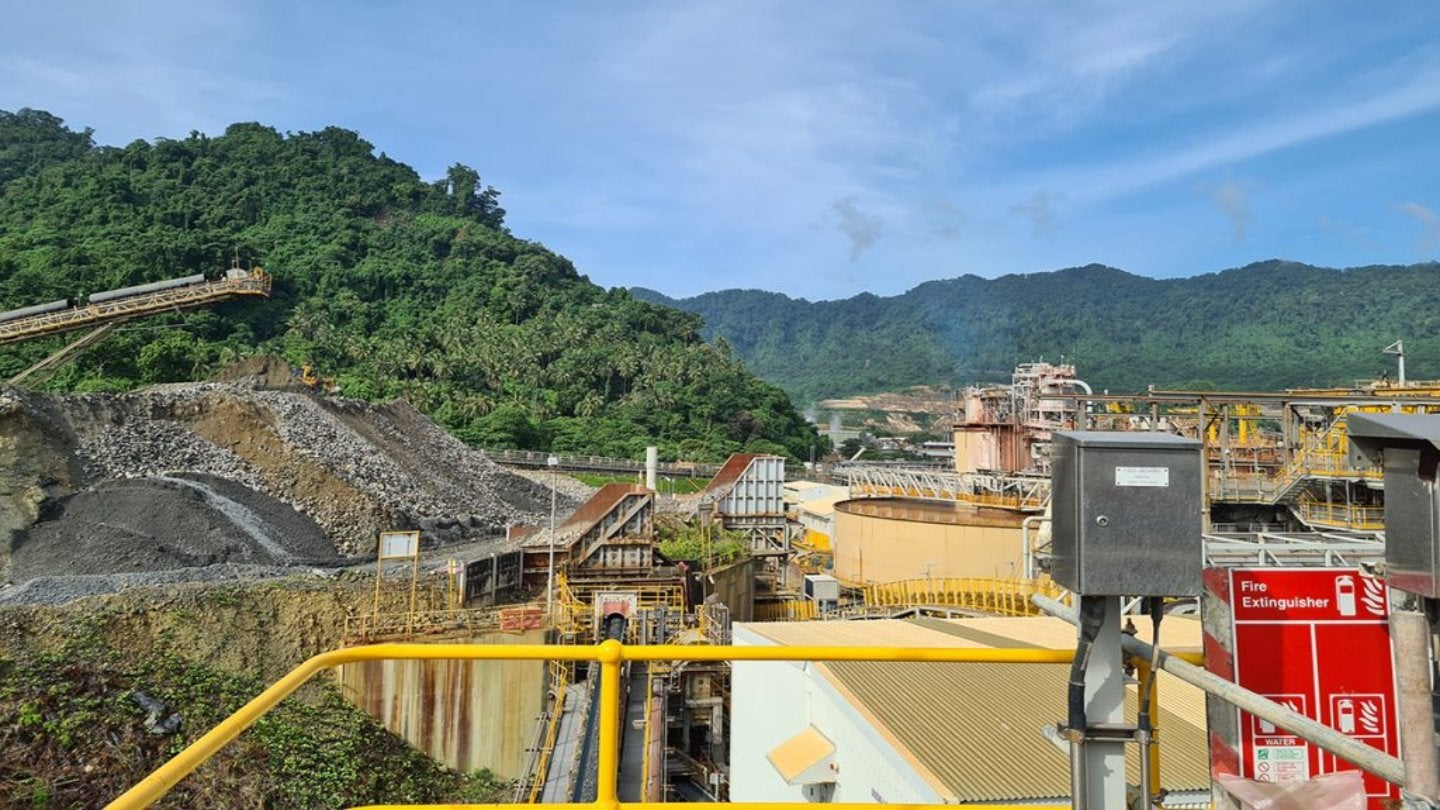

In 2024, the Lihir gold mine in Papua New Guinea produced around 614koz of gold.

The Buzwagi gold mine located in the Shinyanga region, United Republic of Tanzania, was officially closed in July 2022.

Bulyanhulu gold mine is an operational underground mine in Tanzania, operated by Twiga Minerals.

The Aurizona gold mine, located within the Maranhao state, Brazil, is being expanded as an underground mine.

The Bisha project is an open pit mine located in Eritrea and mainly produces copper, zinc, gold and silver ore.

The Fimiston open-pit mine, also known as Super Pit and Golden Mile, is the largest open-pit gold mine in Australia.

The Selinsing gold mine is an open-pit gold mine located at Bukit Selinsing in Pahang State, Malaysia.

The Twin Hills gold project in Namibia is expected to have a mine life of 13 years.

The mine design and reserves of the Arcadia lithium project in Zimbabwe were updated in a direct optimised feasibility study.

The Boddington gold mine (BGM) employed autonomous haul trucks in 2021 to enhance productivity and safety.

Orway Mineral Consultants (W.A) Pty Ltd and Process IQ Pty Ltd announced they have formed an incorporated JV, Orway IQ Pty Ltd, to deliver a remote optimisation consulting service.