The Bisha open pit mine is located approximately 150km west of Asmara in Eritrea.

The mine was originally developed by Canadian gold miner Nevsun Resources. The mining licences were held by the company’s Eritrean subsidiary, Bisha Mining Share Company (BMSC).

The State of Eritrea had a 10% free carried stake in the project. Another 30% stake was held by the state-owned Eritrean National Mining Company (ENAMCO).

Construction work at the site started in September 2008. Gold production began in February 2011. Copper production from the mine commenced in December 2013, followed by zinc production in October 2016 after the completion of the zinc expansion project.

In 2019, Zijin Mining acquired Nevsun Resources’s 60% stake in the Bisha mine. Zijin Mining currently owns a 55% interest in the mine and ENAMCO holds the remaining 45%.

Bisha is estimated to have a remaining mine life of six years. The mine processes 2.4 million tonnes a year (mtpa) of copper-zinc-gold-silver ore.

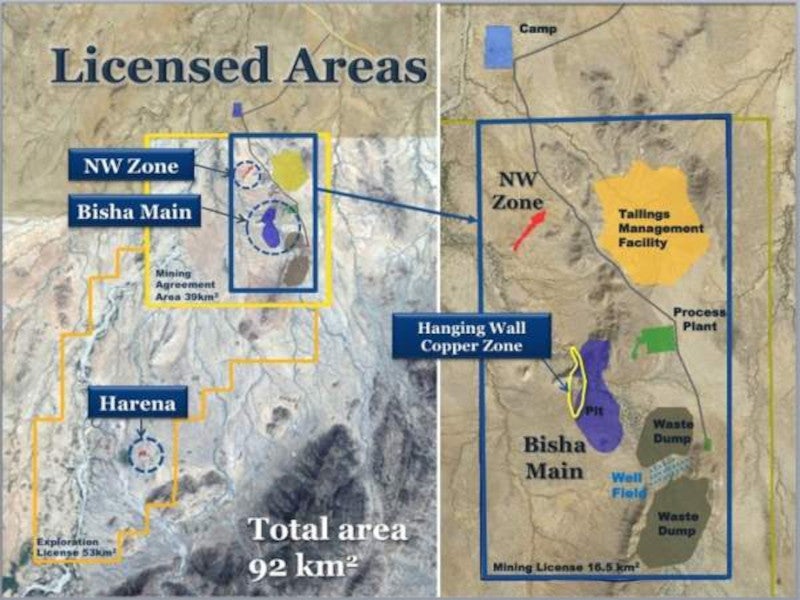

Location of the Bisha project

The Bisha project is located 150km west of Asmara in the Gash-Barka region of Eritrea, East Africa. It includes mining licences covering 16.5km², a mining agreement covering 39km² and an exploration licence for another 71km².

Two other mining sites – Bisha main and the north-west zone – also lie within the mining licence of the Bisha project. The exploration licence holds a satellite deposit called Harena, to the northwest of the Bisha main zone.

The Hanging Wall Copper Zone is located to the west of the Bisha sulphide deposits.

Geology and mineralisation

The mine is composed of upper greenschist to lower amphibolite grade volcanic and sedimentary formations from the Neoproterozoic period, located within the Augaro-Adobha Belt. The geological composition includes a lower sedimentary sequence containing carbonates, fine-grained siliciclastic rocks, and siliceous iron formation.

The VMS mineralisation of the Bisha project lies in the tightly folded inter-layered felsic tuff, metasedimentary and metavolcanic units. It is enriched in zinc and copper with significant amounts of gold and silver. The deposits occur in three different layered zones.

The surface oxide zone of 35m thickness consists of silver and gold, a supergene zone of 30m thickness lies below it and is copper enriched, and at depths below the supergene region lies the zinc and copper-rich primary sulphide zone.

Reserves at the Bisha open-pit mine

The mine is estimated to contain proven and probable reserves of 3.09mt of zinc graded at 3.75% and 800,000t of copper graded at 0.97%, as of 2023.

Mining methods at the Bisha project

The Bisha main and Harena deposits are mined using conventional open-pit mining methods. At Bisha main, 65t haulage trucks and 10m³ excavators are primarily used for in-pit waste haulage in 5m benches. The Harena pit also follows a similar approach with the same mining fleet and 5m benches.

Waste rock is transported to various rock storage facilities based on geochemical characteristics and operational timeframes. Some mineralised waste is stockpiled near the pit for potential recovery in the event of a rise in commodity prices.

Ore processing

The Bisha mine started operations with the completion of the first phase of the project, which included a carbon-in-leach (CIL) processing plant and other associated infrastructure.

The oxides treated with CIL process technology produce trade-worth quality of gold and silver. The second phase incorporated a copper concentrator at the site while the third phase added a copper/zinc concentrator.

Site infrastructure

The mine can be accessed via a paved road from Asmara to Akordat, and through an upgraded all-weather unpaved road from Akordat.

The primary water source is raw water pumped from 19 water bores, with most of the supply coming from ten bores situated in the Mogoraib aquifer.

The mine and processing plant receive electric power from a power station located next to the process facilities, which is fuelled by diesel.

The accommodation facility is 5km north-west of the plant site and can house up to 900 people. It includes facilities such as accommodation, kitchen, dining, recreation, laundry, water treatment, sewage treatment, incinerators, and emergency power.

Contractors involved

The technical report and 2016 resources and reserves update for the mine were prepared by SRK Consulting, a mining consultancy company.

DomeShelter Australia, a fit-for-purpose fabric shelter supplier, designed and manufactured two shelters for heavy vehicle maintenance at the mine.