Hydrographic surveys are the measurement and description of features which affect maritime navigation, marine construction, dredging, offshore oil exploration/drilling, and a variety of water-related activities.

While typically a core service to the offshore oil and gas industry, hydrographic surveys are still widely applicable to all types of mining, particularly when material processing such as washing, is conducted on-site.

Environmental regulation limits the amount of water that can leave the site, so the most common form of storage is earth-filled embankment dams.

When storing wastewater from processing the tailings are often left suspended in the slurry with the goal of letting the water evaporate, while the solids drop out of suspension due to gravity. This leads to the inevitable closure of the dam as it no longer has any capacity to store water.

Both safety and cost are major considerations for any project with tailings dams, as the water can often become toxic from the processing and the volume of water is generally large and therefore the ponds are required to be as well.

Management and monitoring of the condition of the ponds are often difficult because to conduct “manned assessments” would generally require placing people in the line of fire.

At sites with particularly large ponds, this would require people to venture out over the water, many hundreds of meters from shore and within the reach of rescue.

Cross Solutions for over a decade have been innovating in this space, developing a range of systems that reduce the risks and improve the efficiency of hydrographic surveys in tailings ponds.

Un-manned, autonomous, remote-controlled, vessels have been specifically developed for the hydrographic survey of hazardous material ponds and tailing dams.

One such type of agent, caustic soda, Cross Solutions has particular experience with, it is naturally corrosive to living tissues, causing in high concentrations, severe chemical burns.

It is also corrosive to many metals which makes it also difficult to engineer solutions that can be inert to the water they are intended to be placed in.

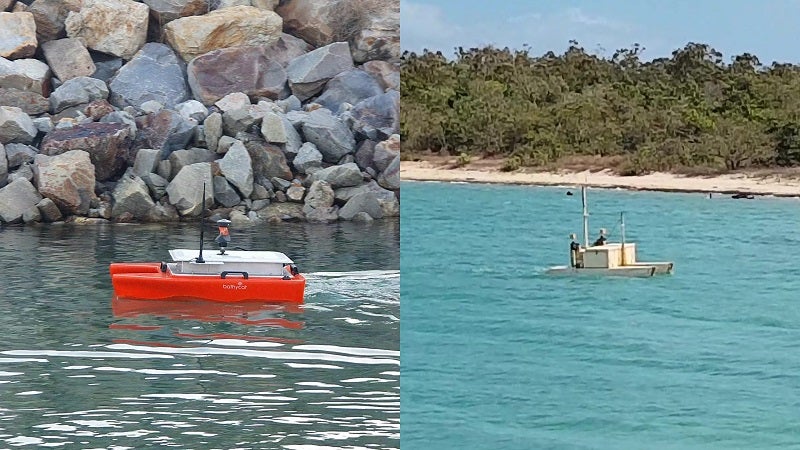

The caustic cat, our original MK1 autonomous vessel, had a control box the size of a briefcase and it weighed over 10kg, with advancements in technologies and the continued pursuit to innovate many of the control systems have reduced in size allowing for smaller vessels and difference payloads.

Sporting up to a dual-frequency depth sounder, our newest and smallest vessel the Bathycat can be hand-launched, requiring minimal access to the water.

The dual-frequency sounder can provide both ‘Top of Sludge’ and ‘Bottom of Sludge’ readings, and with either the typical RTK GPS positioning or also Total station positioning for satellite deprived environments.

This allows for accurate survey under structures (such as outlet pipes and walkways) and the dual-frequency data can be modelled to provide an assumed ‘final construction depth’ while also a current depth. This information supports the calculation of metrics such as volumes of sedimented material, volume of water, and total capacity calculations.

This 3D data has also been combined with survey data from our Maptek long-range laser scanning solutions to provide complete 3D As-Constructed models of earthen ponds, in incredible detail, which can be used for doing accurate forecasting. Such as what dam level changes might occur with particular rainfall events.

For exceptionally large ponds we have developed a vessel similar in size to a small tender vessel. While requiring adequate access (such as a ramp), the vessel is large enough to brush off bad weather conditions such as significant chop or wind. Its increased size also allows for larger more powerful radio configurations, which makes it more practical over larger ponds and areas. This vessel is suitable for use in ports and river mouths where the open water conditions may put other smaller remote vessels into precarious situations.

Solving unique problems for our clients is a key focus of our business. If you are failing to find a solution that works for your operation, be sure to contact on of our offices to get more information on any of the systems described here, or we can investigate providing you with a more tailored solution.