Why KO₂ Self-Rescuers Are Supplanting Filter Devices: Lessons from Mining, Railway & Process Industries

Chemical-oxygen (KO₂) self-contained self-rescuers (SCSRs) are increasingly replacing filter-type devices in high-risk industries. These devices not only purify air but also generate oxygen and absorb carbon dioxide, providing breathable air in a closed circuit independently from the ambient environment, even when the surrounding atmosphere is toxic or oxygen-deficient.

Below are examples from mining, rail, and process industries showing how real accidents reshaped safety standards — and that’s why many companies are now moving to KO₂-based respiratory protective equipment (RPE) using a risk assessment approach.

Case Studies: Mining Industry’s Shift from Filter Devices to Self-Contained Self-Rescuers

In the Republic of South Africa, a series of mine fires — Kinross (1986), Ermelo (1987), and Middelburg (1993) — claimed more than 260 lives. These events exposed the limits of filter-type self-rescuers. In response, the Mine Health and Safety Act (1996) required every underground miner to carry a self-contained self-rescuer compliant with SABS 1737 standard, which is now known as SANS 1737.

In the United States, a series of fatal incidents exposed the limits of filter-type self-rescuers. The Sago Mine explosion (2006) in West Virginia and subsequent Aracoma Alma and Darby disasters the same year showed that filter devices fail in oxygen-deficient environments. These events led to the MINER Act of 2006 and updates to 30 CFR § 75.1714, requiring that every underground miner have immediate access to an MSHA- and NIOSH-approved self-contained escape breathing apparatus.

After the Soma mine disaster (Turkey, 2014), where 301 miners died mainly from carbon monoxide poisoning, Turkey’s Ministry of Labour and Social Security introduced stricter rules on emergency breathing devices, driving widespread adoption of self-contained systems.

Railway: Regulatory Shift After Chlorine Disasters

Two U.S. railway accidents underlined the same truth.

- Graniteville, South Carolina (2005): a Norfolk Southern train collision released chlorine gas, killing 9 people and injuring over 250.

- Macdona, Texas (2004): a similar crash caused 3 deaths and multiple injuries from chlorine exposure.

Following investigations, the Federal Railroad Administration (FRA) updated emergency preparedness standards. Rail companies handling hazardous materials were urged to equip personnel with self-contained breathing apparatus or escape breathing devices, with a supply of breathable gas, not just filter masks, to ensure survivability during chemical releases.

Oil, Gas & Chemical Industries: A Risk-Based Transition

Refineries and chemical facilities are adopting the same approach. In such emergencies, where gases like hydrogen sulfide, chlorine, ammonia may mix, filters may not always be able to protect workers if oxygen is low or gases concentrations are high.

A risk-based safety strategy, therefore, favors emergency escape breathing devices (EEBDs) or KO₂-based self-contained self-rescuers, ensuring protection even in oxygen-deficient or multi-gas conditions.

How KO₂ Technology Works

Potassium superoxide (KO₂) reacts with exhaled moisture and carbon dioxide to release oxygen while absorbing CO₂. This closed-circuit system allows a person to breathe safely in an unbreathable atmosphere — a key advantage over open-circuit filter respirators that depend on surrounding air quality.

Why KO₂ Self-Rescuers Outperform Filter Devices

- Effective without ambient oxygen: generate O₂ and absorb CO₂, protecting in toxic or depleted atmospheres.

- Longer duration in a smaller size and three times longer duration time while waiting for rescue.

- Maintenance-free and durable: no high-pressure cylinders; low life-cycle cost; long shelf life.

- Compact and ergonomic: easily belt-worn or stored in refuge chambers or escape caches.

- Field-proven reliability: trusted for decades in mining, now expanding into maritime, railway, oil, gas, and chemical industries.

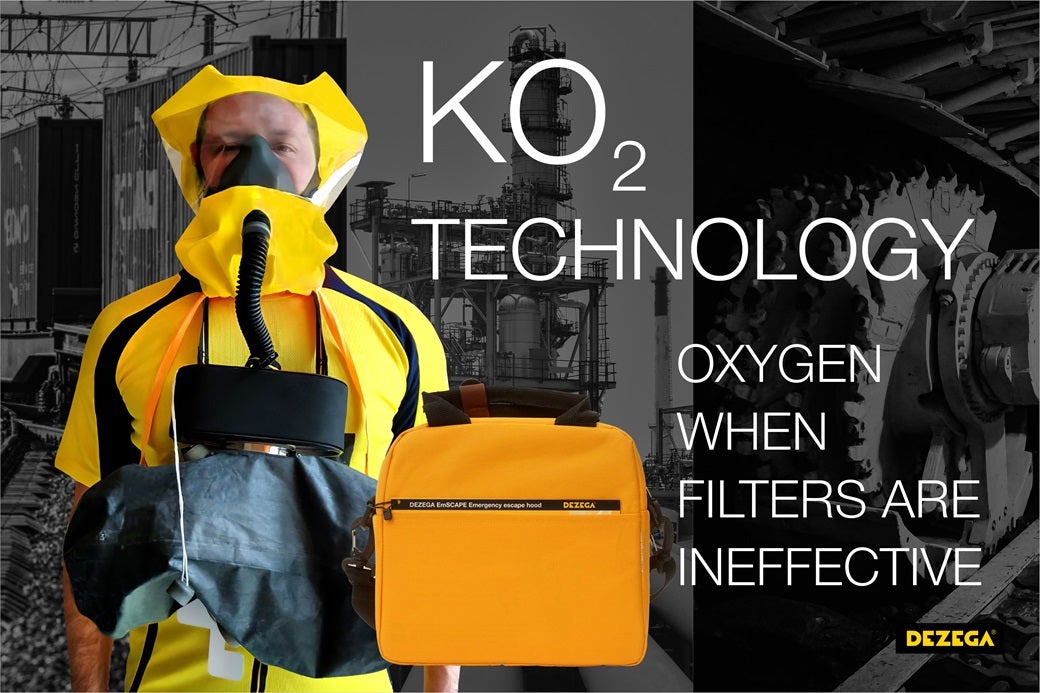

EmSCAPE: A Modern KO₂ Emergency Escape Breathing Device for Multi-Industry Use

EmSCAPE, developed by DEZEGA, brings mining-grade reliability to other high-risk fields — including refineries, maritime operations, firefighting, and tunneling.

It provides instant oxygen flow, compact design, and user comfort under stress, making it ideal for emergency escape scenarios where every second counts.

The shift from filter masks to KO₂ self-contained self-rescuers is more than a technological upgrade — it is a change in safety philosophy.

After decades of evidence from mining and industrial disasters, regulators and safety leaders recognize that only self-contained oxygen-generating systems ensure high level protection in oxygen-deficient or highly toxic emergencies.

For industries committed to the highest standards of worker safety, adopting KO₂-based self-rescuers like EmSCAPE means readiness, resilience, and confidence when it matters most.