The best way to post-weld finish stainless-steel is electropolishing, which is an electrochemical process that increases density of the chromium throughout the weld surface and therefore the ability to create an oxide film.

The corrosion resistance of stainless-steel arises from a chromium oxide film that forms a protective layer naturally on the surface of the steel. The oxide film is extremely thin but strongly adherent and chemically stable, which is commonly referred to as ‘passive’. The film is formed when chromium reacts with oxygen

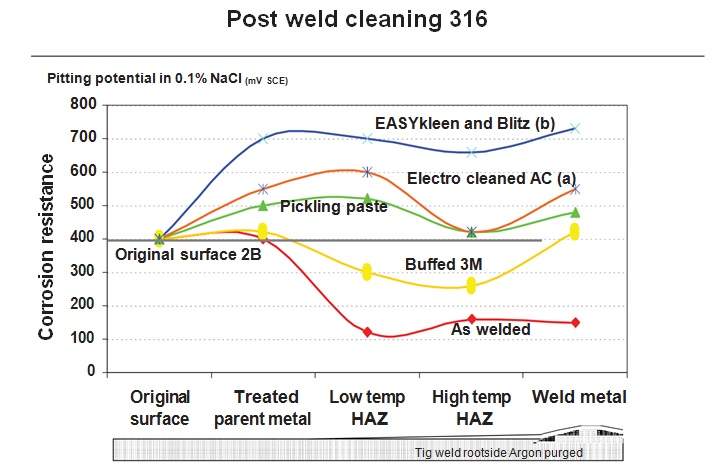

The high temperature of welding results in severe chromium depletion not only at the weld surface but through out the heat affected area. Therefore removing surface material such as oxide scale is only half the job as the weld area is still chromium depleted relative to the parent stainless-steel.

Critically when the weld is depleted of chromium its corrosive resistance is severely reduced. The weld is therefore vulnerable to corrosion and what is often referred to as tea staining and of course it loses its reflectance and cosmetic appeal.

Electropolishing selectively dissolves the microscopic high points of the stainless and selectively removes iron so increases the chromium density and creates a microscopically smother surface on which bacteria contaminates cannot bind or hide.

In the past Electropolishing could only be performed by the immersion of the work piece in electrolyte solution, which wasn’t always possible, practical or cost effective.

With the mepBLITz and EASYkleen range of machines, it is now possible to weld on-site or in the workshop and only seconds later finish the weld with an amazing chromium dense mirror-like sheen.

The machines require minimal labour time and thus yield faster production than other cleaning processes. The mepBLITz uses a food grade acid that combines a phosphoric acid with several sequestering agents to deliver a dramatic improvement in operator safety.

The mepBLITz and EASYkleen range of machines will return the characteristic properties of stainless steel to maximum effect being passivated chromium rich, metallically clean and free from stress, a smoother surface with reduced microscopic cracks, minimum absolute surface area and chemically passive.