Roobuck’s feature-packed tunnel lighting system – safe, efficient, convenient and durable – has now been released on to the market.

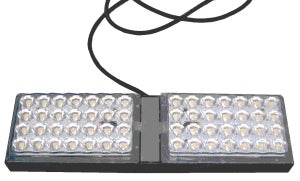

Extra low 32V, waterproof encapsulated high output IP67 LED modules, linked by infinitely variable cable looms, now offer compact, easy to install heavy-duty lighting systems for use on mining tunnels, and more.

For underground coal mine operations optimising safety is a given, especially when selecting from electrical equipment options. Roobuck tunnel lighting systems now offer real choice in terms of safety, servicability, cost efficiencies, and transferability of lighting installations, whether they be underground work areas, tunnels, wet areas/washeries, rigs, shutes, or walkways.

Normally powered by 240VAC or 110VAC, and formerly of the traditional flourescent tube type, or even more recently deployed LEDs, such lighting systems were still deficient. Mines had to pay careful attention to issues of safety and hazards, layout design was at times compromised or limited, maintenance and operating costs were high, and installation, removal and relocation operations remained complicated.

Australia’s first ELV tunnel lighting system has been designed and manufactured by Roobuck, in Australia, with approval to carry the "Australian Made" logo.

The total system comprises a variable number of LED tunnel light modules connected via junction boxes and is powered from a step-down transformer with 32VAC in the secondary. It is designed for general lighting immediately outside hazardous areas in underground mines. The light modules can also be used individually, e.g. for application at coal processing plants, either using all Roobuck equipment, or the operator’s transformer, where suitable.

The light model is coded RLTA1 and meets EMC standard. Safe operation is assured as it is powered from 32VAC and the whole light module is completely encapsulated, so IP67 standard is guaranteed. All electrical leads comply with mining standards and they are permanently attached to the light. The cable specs can also be specified by the customer.

The default transformer is a 240/415/1,000VAC ingress to 32VAC egress step-down transformer complying with mining standards for 1kVA capacity. There are two types of junction boxes; the large junction boxes direct power to one loom with a number of LED modules, while the small junction box powers only two LED modules.

All electrical cables connecting junction boxes and the transformer comply with mining standards. Customers can also choose to use their own transformer, junction boxes or cables if preferred, and they meet the standard.

The three basic components – transformer, junction boxes and LED light modules – will be interconnected in different configurations, according to particular needs and requirements.

In summary:

ELV lighting systems offer various features the industry has never seen before, namely:

- Extra low voltage (i.e.32V) makes it completely safe for mining and other risk applications

- Low maintenance costs, as such low-voltage operation allows maintenance work to be done on live operating systems with safety

- IP67 standard and LED light source make the lighting very robust. With LED lights, there is no need to replace the lamp, bulb or tube

- Full encapsulation means no flashpoint incident if the light module becomes wet

- Installation could not be easier; you can quickly mount up a light and connect to a junction box in seconds. Therefore, the system is particularly suitable for temporary deployment such as with a longwall installation. It can be quickly dismantled for use in other or future installations

Please note: a test report from a NATA-accredited laboratory, design risk assessment document and installation instruction manuals are readily available for customers, in compliance with mining regulations.