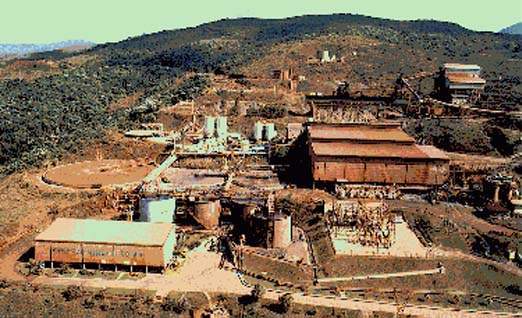

Samarco Mineracão’s Alegria iron ore mine is in Brazil’s Iron Quadrangle, about 4.5km north of the depleted Germano deposit, within the districts of Mariana and Ouro Preto in the state of Minas Gerais. The process plant pumps concentrate via a slurry pipeline to facilities at Ponta Ubu on the Atlantic coast that include two pelletising plants and a shipping quay.

BHP Billiton and CVRD (Vale) each has a 50% holding in Samarco. Production commenced at Alegria in 1992. The operation employed 1,336 people directly and more than 2,000 via contractors in 2005.

The company implemented an optimisation project to increase concentrator and pelletisation capacity in the short term.

It also invested in a new concentrator and pelletisation plant, mine expansion, port improvement and a second slurry pipeline that began operations in 2008. Samarco produced 8.5Mt of iron ore in 2008.

However, due to reduced global demand in 2008, the second and third pellet plants were temporarily suspended. While the two pellets have subsequently been restarted, they will continue operations based on the demand globally.

Geology

The deposit consists of low-grade itabiritic ore. Alegria’s certified mineral reserves totalled 769MT by 30 June 2009 graded at 44.3% Fe. Probable resources stood at 821Mt at 41.5% Fe. Measured resources totalled 1238Mt at 42.2% Fe while indicated resources were 682Mt at 38.1% Fe, sufficient to support mining for 39 years.

Iron ore mining

Itabiritic ore is excavated by bulldozers, loaded by front-end loaders into 177t-capacity trucks and taken to a crushing and screening plant in the blending yard. The ore is blended and stored before transport by belt conveyors to the surge pile.

An overland conveyor system transports the ore over a distance of 4km to the beneficiation plant at Germano.

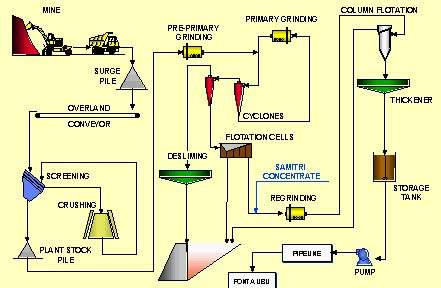

Germano beneficiation plant

At the Germano beneficiation plant the ore is screened, crushed and classified to feed the primary mills. This circuit assures sufficient reduction of the iron ore particles. It is then deslimed, deslimed, with the ultrafine material being removed in cluster cyclones before conventional flotation where waste material such as silica is separated from the iron particles. The ore is reground and enters a column flotation circuit.The addition of a roller press in 2004 improved productivity by 7%. The resulting concentrate is slurried with water for pipeline transport.

The concentrator is capable of an annual production of 24Mt of iron-ore concentrates a year. Its output in the 2008 financial year was 8.5Mt.

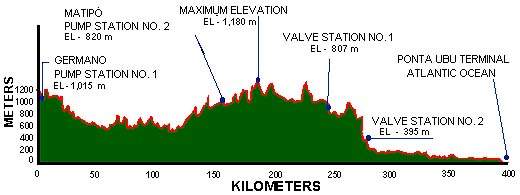

Slurry pipeline

The slurry pipeline takes ore from the Germano plant to the Point Ubu pellet plant and shipping facility at Espírito Santo on the Atlantic coast. At 396km, this iron ore slurry pipeline is the world’s longest and offers environmental safety and 99% average availability. The new slurry pipeline built in 2008 also measures 396km.

Two pump stations and two valve stations regulate internal pressures and maintain flows at an average speed of 6km/h with a flow rate of 1,200m³/h. The pipeline, designed to move 12Mt/y, is now operating at over 15Mt/y owing to advances in pumping and monitoring technology. A new pipeline will be built in conjunction with the new concentrator and pellet plant.

At the Ponta Ubu pipeline terminal, incoming slurry is thickened and then stored in tanks that feed vacuum filters. These remove the remaining water from the slurry.

The concentrate’s moisture content is adjusted and limestone, bentonite and coal added. It is then conveyed to the balling discs for pelletising. The pellets are screened and classified by size before being fired in the induration furnace.

Oversize and undersize materials return to the balling discs. Fired pellets are conveyed to the port stockpile area, which has a 2Mt storage capacity. The final product is direct reduction and blast furnace pellets for steelmaking. The plant has an annual production capacity of 13Mt of pellets, which rose to 14Mt/y in late 2006. Surplus concentrates are sold as pellet plant and sinter feed.

Point Ubu

The pelletising facility on the coast enables Samarco to operate its own port facility at Point Ubu, which can accommodate two vessels of up to 170,000t. The 313m-long by 22m-wide shiploading pier also receives carriers and tankers bringing coal and fuel oil for the pelletising plant.

Third and fourth pellet plant

The third pellet-plant project was approved in October 2005. The new concentrator has a capacity of 7.5Mt/y. Outotec supplied the pellet indurating furnace for the third plant in 2007 under a $200m contract. The pellet plant increased yield capacity by 7.6Mt/y and altered the blast furnace:direct-reduction pellet output split to 50:50.

The installation of the third pellet plant enabled Samarco to process nearly 24Mt/y of ore concentrate. It allowed Samarco to produce approximately 21.6Mt of pellets every year.

In 2011, the fourth pellet plant project with capacity of 8.3Mt/y was approved. A third slurry pipeline running parallel to the two existing pipeline will be installed as part of the project. The new pipeline that will link the mine with the fourth pellet plant and is designed to carry 20Mt/y.

An estimated $3bn will be invested in the fourth pellet plant project. The plant is anticipated to go operational by the first half of 2014.

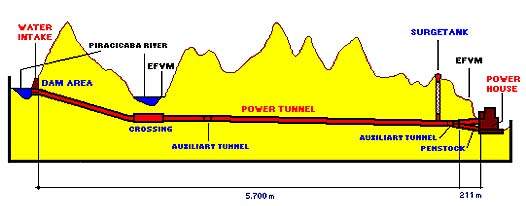

Guilman-Amorin hydro-electric plant

The key to Samarco’s expansion has been the Guilman-Amorin hydro-electric plant, located in Muniz Freire county, Espírito Santo state. Samarco has a 49% interest in this project, in partnership with Companhia Siderúrgica Belgo-Mineira. The power plant has a capacity of 140MW from four 35MW turbines.