The integrated mining, smelting and refining facilities operated by KGHM Polska Miedz SA (KGHM) ranked as the world’s sixth largest refined copper supplier, and the third largest source of silver in 2005.

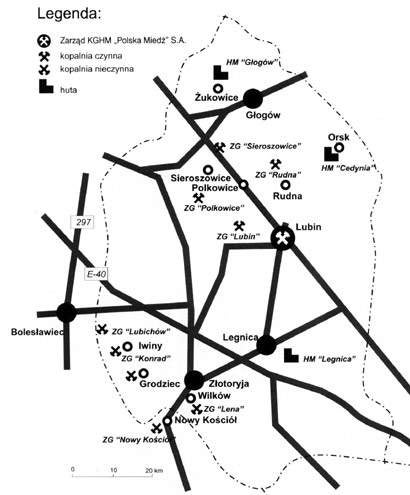

The KGHM Combine was created in 1961 to develop a copper deposit located north of some existing small mines in Lower Silesia, southwest Poland. Four mines were developed between 1961 and 1980. In 1971, KGHM built the Glogów I smelter-refinery, 20km north of the Legnica smelter-refinery which opened in 1959. The Glogów II flash smelter and refinery was completed in 1978.

KGHM added a precious metals plant in 1993 and sulphur treatment units in 1994 and 1998. During 2000, the firm started sinking shafts to access ore below 1,200m depth in the Glogów area. Three have been completed and SW-4 is under construction.

The average group workforce is around 27,000, with its mining and metals operations accounting for over 85% of total KGHM revenues. Employment within the company’s mining operations is around 17,900 people.

GEOLOGY AND RESOURCES

The Legnica-Glogów copper basin extends over a polygonal area of 416km². The stratiform mineralisation occurs where Permian limestone lies against New Red Sandstone within varying combinations of sandstone, shale and dolomite. The proportions of carbonate, shale and sandstone ore types vary from mine to mine and the ore horizon ranges from 1.2m to 20m in thickness, lying at depths of between 600m and 1,200m from surface. The overall average thickness in the mineable zones is 3.38m.

Chalcocite, bornite and chalcopyrite are the most important minerals. KGHM is currently accessing the recently licensed Glogów Gleboki Przemyslowy deposit, which contains ore at depths of 1,100–1,400m equivalent to 26% of the resources currently being worked. As of December 2005, KGHM stated its geological resource as being 1,603Mt, containing 32.2Mt of copper and 23,003t of silver, while industrial ore reserves totalled 922Mt, containing 21.2Mt of copper and 58,496t of silver.

MINING

The Lower Silesian deposit was developed as four mines: Lubin (1961–68), Polkowice (1962–68), Rudna (1970–74) and Sieroszowice (1976–80). Polkowice and Sieroszowice, which shared a concentrator, were merged in 1996. Shaft sinking through aquifers utilised a special freezing method. The deposit is stressed, and is subject to seismic events and rock bursts, so KGHM has developed a sophisticated monitoring system and makes extensive use of rock bolts.

Thicker seams are worked by cut-and-fill but most production relies on room-and-pillar mining on a number of levels; 950m, 1,000m, 1,050m and 1,150m at Rudna, for instance. Until the 1990s, room and pillar mining was restricted to the 2–5m-thick sections, mainly using locally built pneumatic drilling rigs.

Electro-hydraulic rigs have since increased productivity and reduced dilution in these sections, while thin-seam equipment such as the Facemaster 1.5, developed by a joint venture between KGHM and Boart Longyear and now built by Mine Master, has extended mining into thinner seams. LHDs, shuttle cars and, in thicker working areas, Toro 50D trucks, take ore to conveyors that run to the hoists.

KGHM also mines salt above the copper seam at Sieroszowice, using a roadheader. The mines traditionally worked three shifts/day for five days, with extra shifts on Saturdays as required, but during 2003 a new multi-shift system was introduced.

PROCESSING

The concentrators at Lubin (23,000t/d), Polkowice (22,000t/d) and Rudna (43,500t/d) use a conventional flotation process to produce 25–26% copper concentrates for the shaft smelters at Legnica and Glogów I and the Glogów II flash smelter. Three-stage milling with rod and ball mills feeds flotation circuits. Pressure filtration yields concentrates, while tails are dewatered. There is a centralised tailings disposal system. Recovery rates in the mid-1990s were 88–90% for copper and 83–88% for silver, but have improved since. Optimising the concentrator capacity and transport to the HM Glogów smelter remain KGHM priorities, as does one station flash smelting.

PRODUCTION

Copper production increased from 400,000t/y in the early 1990s to almost 500,000t in 2001. In 2003, KGHM mined 25.83Mt of ore averaging 1.99% Cu, and processed 1.88Mt of 26.76% Cu concentrates. Electrolytic copper output was 529,616t, crude lead 20,134t, metallic silver 1,223t, doré silver 135t and gold 356kg. Other products included platinum-palladium slime, selenium and over 600,000t of sulphuric acid.

In 2004, the total output was 550,000t of copper and 1,344t of silver. During 2005, the company mined 30.4Mt of ore averaging 1.89% Cu, and this lower grade more than offset the higher tonnage produced, so copper-concentrate production fell from 2.05Mt to 1.98Mt, although the copper grade of the concentrate was increased by better recovery. Electrolytic copper production rose from 550,000t to a record 560,000t thanks to the increased use of imported charge materials in order to make optimum use of the smelter capacity. However, these materials contained relatively little silver, so that total silver output fell from 1,344t to 1,244t in 2005.