The Galmoy mine is situated in County Kilkenny, 110km south west of Dublin. Initially owned and operated by Arcon International Resources Ltd, Galmoy employs about 200 local people and a further 25 contractors. The mine came on stream in 1997 and was Ireland’s first new underground mine for 20 years.

In May 2005, the Canadian-based company, Lundin Mining Corp., completed a merger with Arcon and in November 2006, the company further increased its zinc-mining portfolio through a merger with Eurozinc Mining.

As well as Galmoy, Lundin now owns Zinkgruvan and Storliden in Sweden, and Neves Corvo in Portugal.

GEOLOGY AND RESERVES

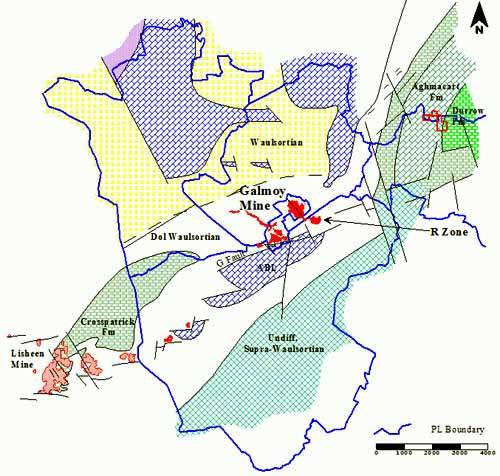

The Galmoy orebodies are breccia-hosted, generally stratabound lenses of predominantly massive sulphides consisting of sphalerite, argentiferous galena and pyrite / marcasite in variable combinations. Hosted in Lower Carboniferous rocks, they occur at the junction of an argillaceous bioclastic limestone (below) and the dolomitised Waulsortian limestone above.

Four zones are recognised: G, CW, R and K, each with its characteristic ore type. The G zone contains more lead and iron than the CW, while the R zone’s lead and silver grades are significantly greater than anything found at Galmoy before.

In places, some of the ore can be quite heavily weathered, a feature that led to significant mining problems in the CW orebody during much of 2001.

Following an audit and reclassification, end-2005 reserves were stated to be 2.89Mt of proven ore grading 15.9% zinc, 4.6% lead and 31g/t silver. The mine’s probable ore tonnage was 660,000t averaging 9.6% Zn, 2.0% Pb and 5g/t Ag.

MINING AND MILLING

Galmoy is exclusively an underground operation. Initially the mine used room-and-pillar methods exclusively but subsequent modifications introduced both benching and drift-and-fill systems where conditions are appropriate, as a means of maximising ore recoveries. At the same time the mining method is designed to ensure that no waste rock needs to be hauled to the surface.

Instead, waste is stored underground in worked-out areas of the mine, so providing additional support to the workings. In addition, between 80% and 90% of the mill tailings are returned underground following thickening and the addition of 3% to 8% cement as a binder, the tailings paste being handled by a GEHO positive displacement pump.

The mine is equipped mainly with Sandvik Tamrock drilling and loading equipment, with Normet and Getman bulk explosives charging vehicles and other utility machines. A new LHD and a new truck added in 2004–5 were expected to be the last capital additions needed for the current life-of-mine plan.

In its concentrator plant, Galmoy uses a conventional two-stage flotation circuit to recover separate lead and zinc concentrates. Initial crushing / grinding using conventional SAG mill / cyclone / ball mill circuits is followed by lead and then zinc recovery by flotation using Wemco cells. Concentrate thickening is followed by Dorr Oliver filter-press dewatering.

The original design capacity of 650,000t/y was raised to 750,000t/y in 2002–3 but ore output never matched this throughput rate.

However, increased mining rates in 2004 and 2005 indicated that a sustainable rate of 700,000t/y is possible. In 2005, the mine produced 644,058t of ore, 4.3% more than in the previous year, at a higher average zinc grade (13.7%) but with less lead (4.0%).

Concentrates are transported to New Ross port, Waterford, about 80km away, where they are loaded on to ships for transport to smelters, located mainly in Europe.

ENVIRONMENT

Galmoy’s surface facilities make a very small footprint on the Irish countryside. The tailings that remain following the separation of the coarser-sized material are pumped to the nearby tailings ponds. These have been designed to preclude any possibility of leakage, and are now being reclaimed sequentially by covering them with organic material and planting suitable species of grass.

Arcon also committed to protecting domestic water supplies for local communities that might be affected by the mine’s pumping, with the installation of a district water main to supply local consumers.