The Bayóvar Phosphate project is located in the Sechura desert in Piura, Peru. The Bayóvar mine is an open-pit mine with a reserve base of 238mt of phosphate.

The project was earlier solely owned by Vale. In July 2010, Vale sold minority stakes in the project to Mosaic and Mitsui. Vale retains control of the project with 40% stake. Mosaic owns 35% stake in the project and Mitsui owns the remaining 25%.

The project was officially inaugurated in August 2010 but production had already commenced in July 2010.

The mine has an estimated life of 27 years. The project is capable of producing 3.9Mtpa of phosphate concentrate with a minimum grade of 29% of phosphorus pentoxide, which is mostly used in fertilisers. Vale has invested $556m in the project.

The mine is being operated by Vale’s subsidiary Miski Mayo. Vale gained the Bayovar project in a public auction in 2005 after having committed to build the project within five years. The cornerstone for the project was laid by Vale on 8 September 2008.

The project includes a phosphate concentrating plant, a 32km highway for the exit of production, a 5km conveyor in the dock, drying and storage for loading, a port with capacity to ship 7.9Mtpa, and a seawater desalination plant. The facilities occupy an area of 8,300ha.

Vale will export the processed phosphate to South and North Americas, Oceania and Asia. In the long-term, Vale will market phosphates to Brazil.

Ore processing at Bayóvar

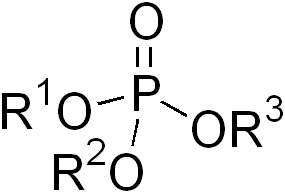

The mined ore passes through a concentrating process consisting of successive stages of washing and gravimetric separations using seawater. The process consumes 3,072m³/hr of water a day. The final stage of the process includes washing with desalinated water to remove salts in the concentrate. The residues from the process contain fine and coarse tailings. Chemical reagents are not used at any stage of processing.

Processing of the ore takes place in the desalination plant, which ensures non-interference of water resources in the region. The plant also enables the preservation of groundwater for the people of Sechura.

Transport and handling

The processed phosphate will be exported through the port at Piura. Odebrecht Peru, Brazil’s biggest construction group, was awarded the contract to build the port between Punta Laguna and Punta Aguja in Sechura Province, 4km from the phosphate plant. The port comprises a 16m-wide and 187m-long cargo platform.

In April 2009, TAIM Weser was given the contract to build the conveyor belts and a shiploader with a capacity of 3,500t per hour. TAIM Weser is a company specialising in bulk handling equipment.

The conveyor belts enable the processed phosphate to be loaded into ships.

TAIM Weser is also responsible for rendering a fully automated facility with a capacity of 20,000-75,000dwt. The facility enables phosphate to be transported and loaded into ships. It is designed for grain sizes of 0.8-0.053mm and a material density of 1.4-1.6t per cubic metre.

The facility moves from the ground through a 480m-long tubular belt conveyor to the dock. The raw material is then dumped into a 183.72m-long conveyor, which runs parallel to the edge of the dock and a 162m-long tipper. The material is then tipped into another conveyor connected to the loader.

The loading movements of the facility can be controlled from the control cabin or by radio. The facility is fitted with its own PLC and includes equipment such as limit switches, an anemometer and level sensors.

Environment

Vale submitted an Environmental Impact Assessment study to the Peruvian Ministry of Energy and Mines in 2007, which was approved in April 2008. The EIA found that impact on the ground will be minimal during the construction and operation phase.

The impact on air quality in terms of the generation of particulate matter would also be minimal except during quarrying and road building.