IMA Bulk Ore Sorting System (BOSS) pilot test showed significant improvement in Ni-Cu ore grade.

In the case study, mobile sorting was carried out with a local contractor’s mobile crusher. The ore was moved to the crusher from the muck pile. Crushed ore was collected into a wheel loader bucket, and then loaded onto a mobile screen, where IMA sensor analyzed the ore from the feed on a conveyor belt. The online analysis occurred at 15s frequency. During this time, approximately 1.5t of primary crushed ore moved below the sensor and was analyzed by scanning.

All the ore, including fines and coarse was analyzed with one scan. The screen gives the option to sort the fines and coarse fractions separately. Screened fractions can be further analyzed and sorted separately.

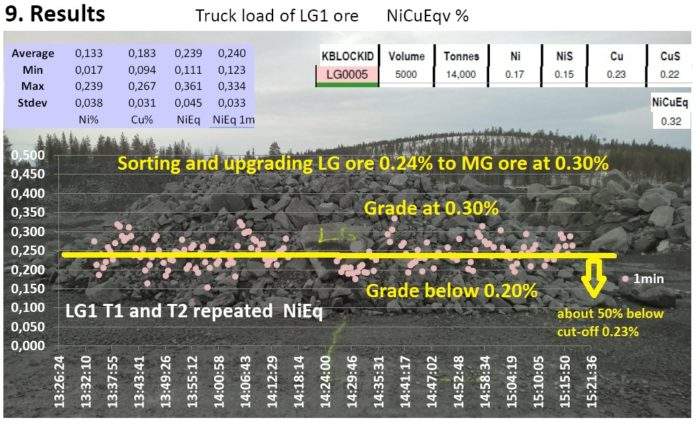

The above results show the sorting of LG resulted in MG ore, which was fed into the concentrator. Cut-off was set at 0.23% and about 50% of LG was recovered to MG grade.