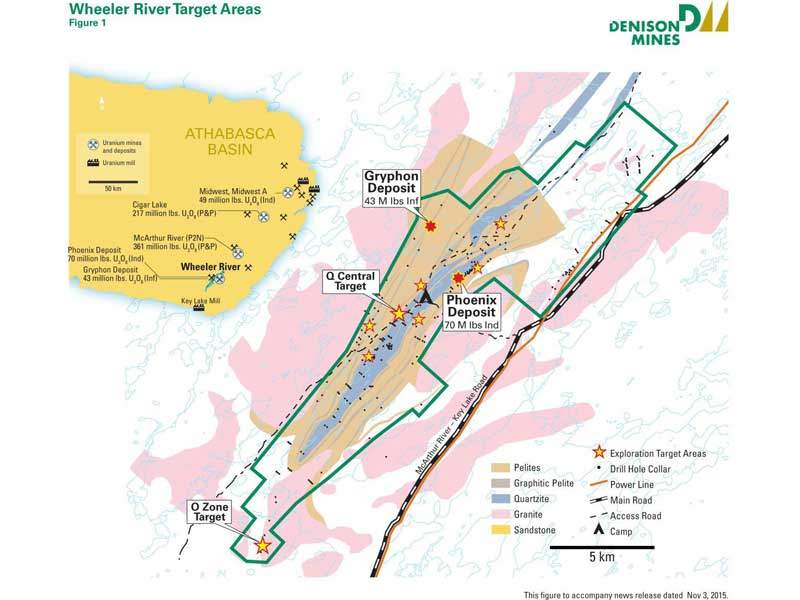

The Wheeler River Uranium Project is located approximately 35km north-northeast of the Key Lake mill, and 35km southwest of the McArthur River uranium mine, within the eastern edge of the Athabasca Basin, in northern Saskatchewan, Canada.

The project is owned by the Wheeler River Joint Venture, in which Denison Mines has a 60% interest and serves as the operator, while Cameco and JCU (Canada) Exploration Company own 30% and 10% shares respectively.

The preliminary economic assessment (PEA) for the project was completed in April 2016, and the prefeasibility study (PFS) is expected to commence in the second half of 2016. The feasibility study is expected to start in 2018 and the construction works are expected to commence in 2021. Commercial production from the project is anticipated in 2025.

The initial investment to bring the Canadian uranium project into production is estimated to be C$560m ($447m approximately). The project is expected to have a production life of approximately 16 years.

Wheeler River Uranium Project geology and mineralisation

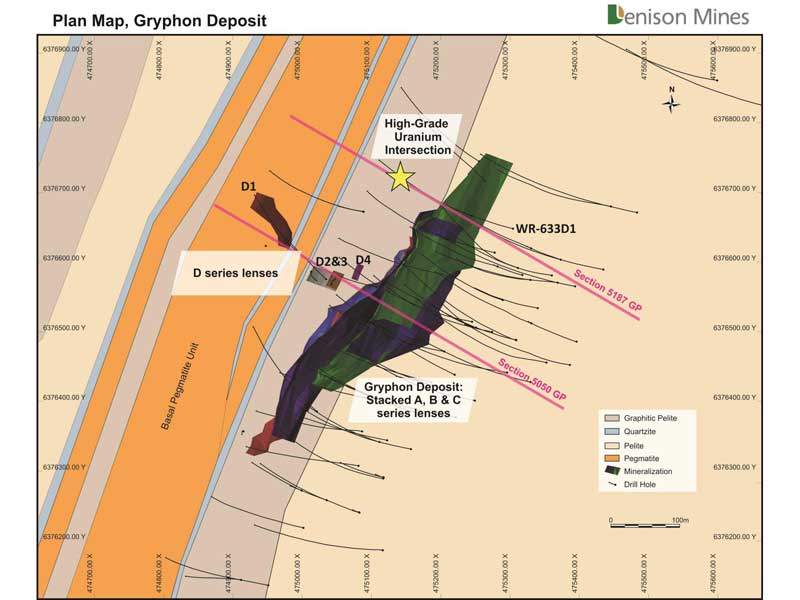

The project will involve the initial development of the Gryphon deposit, followed by that of the high-grade Phoenix deposit. The two deposits were discovered in 2007 and 2014 respectively and are located near the southeastern margin of the Athabasca Basin, below, across and immediately above the sub-Athabasca unconformity, which overlies early Paleoproterozoic and Archean crystalline basement rocks.

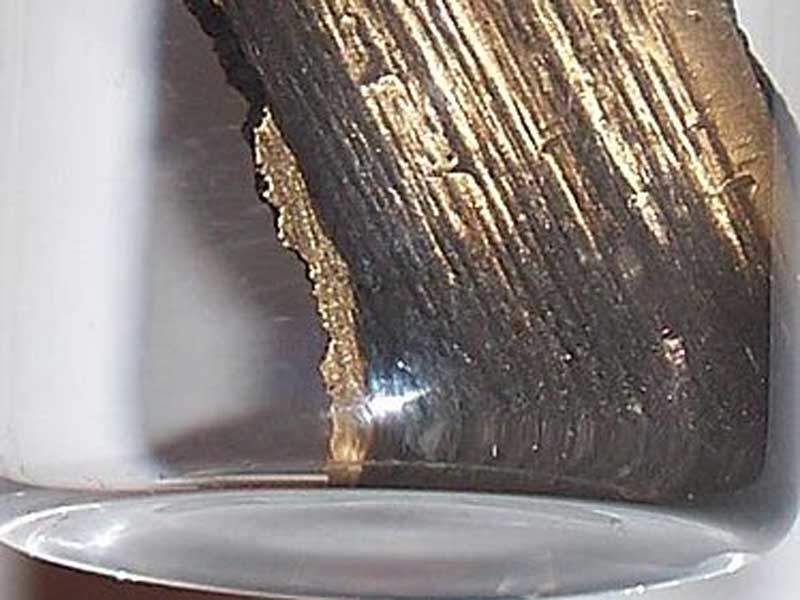

Mineralisation at the Phoenix deposit is hosted horizontally at the unconformity, approximately 400m below surface, with a strike length of approximately 1km. Mineralisation at Gryphon is hosted within the basement rocks, approximately 580m to 850m below surface and approximately 220m below the unconformity.

Reserves and production targets

As of September 2015, the two deposits were estimated to hold combined indicated resources of 166,400t grading 19.14% U3O8, containing 70.2 million pounds (Mlbs) of U3O8. The combined inferred resources were estimated at 842,600t, grading 2.37% U3O8, containing 44.1Mlbs of U3O8.

The Phoenix deposit is expected to produce approximately 7.0Mlbs of U3O8 a year during its estimated production life of nine years, whereas the Gryphon deposit is expected to produce approximately 6.0Mlbs of U3O8 a year during its estimated production life of seven years.

Mining and processing at Denison Mines’ flagship project

The mining methods envisaged for the Phoenix deposit is the jet bore system (JBS) underground mining method integrating freeze wall protection to prevent water inflows, whereas those envisaged for the Gryphon deposit is the conventional longhole open stoping with backfill. The two underground deposits will be connected through a 2.8km-long connection drift.

Denison Mines proposes to use the extra capacity at the neighbouring McClean Lake mill, in which the company has a 22.5% interest, to process the ore at the mine site. The project will necessitate the expansion of the mill’s leaching circuit and the solid/liquid separation circuits.

Infrastructure for the Canadian uranium mine

The electricity required for the project will be sourced from an existing transmission line located adjacent to the project site. A 230kV overhead transmission line and a substation will be constructed at the Gryphon site and diesel generators will be installed to serve as back-up.

Major infrastructure at the Gryphon site will include a production shaft, hoist house and headframe, a ventilation raise, main fresh air fans and mine air heater, an accommodation camp, a fuel storage facility, waste storage facilities and a water treatment plant.

The site will also integrate buildings for an administration office, a change house, a maintenance shop, a warehouse, an emergency services building, and laboratories.

In addition to the freeze wall infrastructure, the Phoenix site will also integrate a ventilation raise collar with main exhaust air fans, and a high-grade slurry load out facility.

Access to the project site is provided by a gravel road connecting with the MacArthur River mine site. The gravel road will be upgraded and a new 45km-long haul road will be constructed from the McArthur River mine site to the Cigar Lake mine, to further connect with the existing provincial roads.

Key players involved

The technical report for the PEA was compiled by SRK Consulting in collaboration with Roscoe Postle Associates (RPA), Amec Foster Wheeler, Newmans Geotechnique and Saskatchewan Research Council (SRC).