The Piedmont Lithium Project is an open-pit mine under development in the Carolina Lithium Belt, a historic lithium mining and producing region in North Carolina, US.

Piedmont Lithium (PLL) 100% owns the project, which was originally explored in the 1950s by Lithium Corporation of America and eventually acquired by FMC Corporation (now Livent Corporation).

PLL plans to conclude a preliminary feasibility study (PFS) for its lithium hydroxide plant in the second quarter of 2020 and a definitive feasibility study (DFS) by the end of 2020.

PLL was granted 404 permit approval from the US Army Corps of Engineers in November 2019, marking a major milestone in the development of the project. It is the only federal permit required for the development of mine and concentrator.

The project was also granted CWA Section 401 Individual Water Quality Certification by the North Carolina Division of Water Resources.

PLL unveiled the results of the updated scoping study in August 2019. Based on the latest mineral resource update published in June 2019, the study extended the life of the project to 25 years.

Piedmont Lithium Project location, geology and mineralisation

A major east coast transportation corridor, Interstate I-85 lies 13km south of the Piedmont Lithium project site. It connects the site to the city of Charlotte. The project area is also accessed by highways maintained by the state.

The property contains three deposits, namely Central, Core and Sunnyside. It includes multiple spodumene bodies containing pegmatite dykes. Mineralisation has been encountered within every hole drilled on the property over 4km of strike length.

Piedmont Lithium Project reserves

As of June 2019, the Piedmont Lithium Project was estimated to contain indicated and inferred resources of 29.1Mt grading 1.11% Li2O and 309,000t of lithium oxide (Li2O) or 764,000t of lithium carbonate-equivalent (LCE).

Mining and ore processing at Piedmont Lithium Project

The Piedmont Lithium Project will use the conventional open-pit method to mine shallow and high-grade lithium. The drilling activities will be performed in four phases, with further expansion in the future.

The project will involve the construction of a spodumene concentrator and a lithium hydroxide plant. The run-of-mine (ROM) ore will be delivered by trucks to a ROM pod and then to a jaw crusher and a secondary cone crusher for resizing.

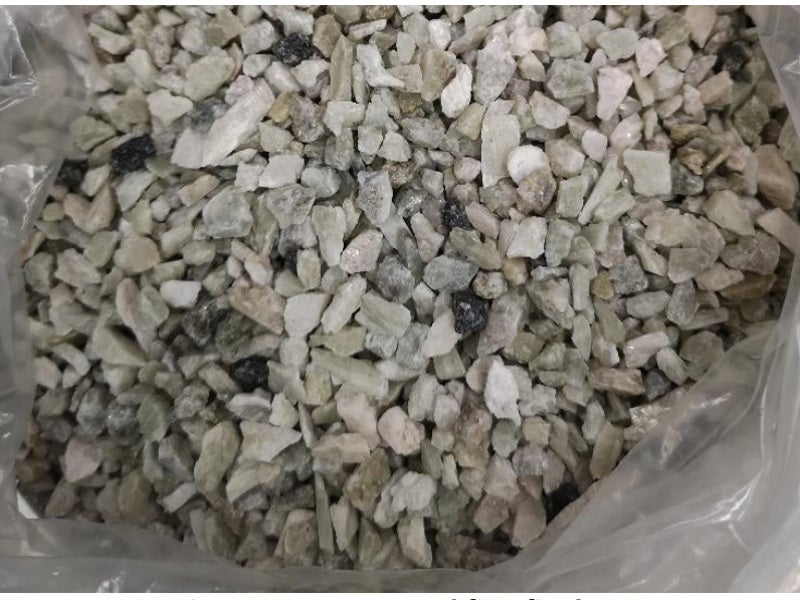

Sized ore will be stockpiled and dilute material will be separated from sized ore before being transferred to a ball mill, which will mill the ore to normal size. The milled ore will be deslimed for scrubbing in high-density attrition scrubbers.

Spodumene concentrate will be recovered through a series of flotation and magnetic separation circuits and processed in wet high-intensity magnetic separators (WHIMS). The final concentrate product will reach the concentrate thickener.

The concentrate will be supplied to the chemical plant to be converted into lithium hydroxide (LiOH). The project aims to produce approximately 489,000t of LiOH with an average grade of 21,260t/y of LiOH over 25 years of mine life.

Approximately one-third of the byproduct potential will be converted into final product and two-thirds of the potential byproduct will be disposed as waste through dense medium separation tailings.

Approximately 1.9Mt of quartz, 2.7Mt of feldspar and 0.3Mt of mica concentrate will be recovered over the mine life.

Infrastructure

Located in close proximity to the lithium processing facilities operated by Albemarle and FMC, the Piedmont Lithium Project site is complemented by the surrounding road and rail infrastructure.

The project is approximately 9km away from FMC’s lithium processing facility in Bessemer and 12km from the Kings Mountain lithium processing facility.

The site is situated 50km from the 2.3GW McGurie Nuclear Power Station and is accessed by CSX and Norfolk Southern railways. The mine site is also accessible by air through Charlotte-Douglas International Airport, which is located 32km away from the project.

The site offers easy access to the power back-up, research and development (R&D) centres for lithium battery storage, major high-tech population centres and downstream lithium processing facilities. In addition, the construction site has ground and surface water sources.

Contractors involved in Piedmont Lithium Project

Primero Group is responsible for conducting engineering studies for the spodumene concentrator.

SGS Laboratories based in Lakefield, Ontario, completed the metallurgical test work on variability and composite samples.

Marshall Miller, a regional leader in mining and geology consulting engineering, is responsible for mine design, mine engineering, scheduling, pit optimisations, scheduling and waste disposal. It is also involved in modelling and pit sequencing, as well as a capital estimate for the mine.

The estimate of mineral resource byproduct was provided by CSA Global.

The contract for environmental activities and flaw analysis was awarded to HDR. It was also involved in the preparation of 401 and 404 permitting applications.

Johnston, Allison & Hord (JAH) was contracted to provide legal advisory services. Roskill is responsible for long-term price forecasting and marketability analysis of lithium products produced from the Piedmont Lithium Mine.