The Makuutu rare earths project is an open-pit mining development by Ugandan company Rwenzori Rare Metals (RRM) in Uganda, East Africa.

The scoping study of the project was completed in May 2021, while stage one of the definitive feasibility study (DFS) was completed in March 2023.

Australia-based IonicRE, a company previously owned 51% of RRM, which increased to 60% upon completion of the DFS in 2023.

The project is expected to have a mining life of 35 years with an estimated pre-production capital of $120.8m.

The first production is targeted for the fourth quarter of 2024.

Makuutu rare earths project location

Makuutu rare earths project is situated 40km east of Jinga and 120km to the east of the capital city of Kampala, in the eastern region of Uganda.

Spread over 298km², the project encompasses three exploration licenses in EL00257, EL00147 and EL00148 and three retention licenses RL00007, RL 1693 and RL00234. Stage one of the development will focus on RL 1693.

Geology and mineralisation

The Makuutu deposit is a type of ionic adsorption rare earth element (REE) clay deposit.

The mineralisation at Makuutu occurs within a tropical lateritic weathering profile of sedimentary rocks such as shales, mudstones and sandstones surrounded by granitic and mafic rocks. The REE mineralisation is concentrated in the weathered profile and dissolved onto fine particles of aluminosilicate clays.

Reserves

The total proven and probable ore reserve at Makuutu rare earths project (stage one) is estimated at 172.9 million tonnes (Mt) with total rare earths oxide (TREO) grading 848ppm, 584ppm total rare earth oxide minus Cerium (TREO-CeO2), 629ppm light rare earth oxide (LREO), 219ppm heavy rare earth oxide (HREO), 296ppm critical rare earth oxide (CREO) and 30ppm scandium oxide.

Mining methods

The Makuutu rare earths project will be developed using conventional open-pit mining methods using a selective mining approach, which will be undertaken on 2m benches.

The near-surface mineralisation, which lies under approximately three metres of overburden, will be mined using free-dig bulk mining methods.

The mining fleet will include 70t excavators, 8t front-end-loaders and 40t haul trucks supported by graders, shovels and bulldozers.

The mining design involves 1m of pre-strip, which will be stockpiled near the pit. The lower rare earth materials will be stockpiled adjacent to the pit, while the mine waste will be dumped into a nearby pit.

The waste and leach residue will be reclaimed after the conclusion of mining activities. The pit will be backfilled gradually, followed by the return of topsoil to the disturbed area as part of a progressive rehabilitation.

Ore processing

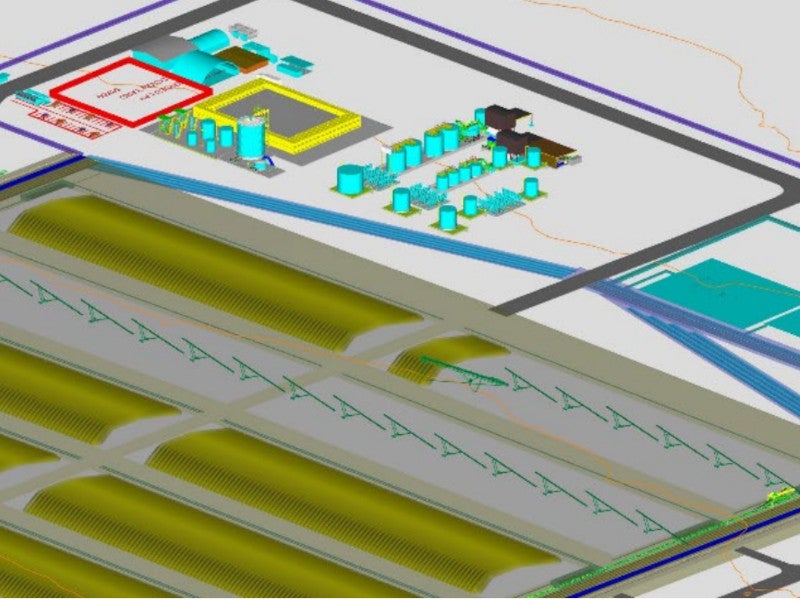

Stage one development is estimated to produce 40,448t of rare earth oxides (REO) equivalent, as mixed rare earth carbonate (MREC), with approximately 71% magnet and heavy REO content.

The proposed metallurgical process for the Makuutu project will involve heap desorption leach extraction, membrane solution purification and staged carbonate precipitation. These stages will work in tandem to extract and purify metals from the ore, resulting in a refined product.

The run-of-mine (ROM) ore will be stacked and heap leached using an acidified salt solution (ammonium sulfate) to desorb and leach the rare earth elements (REE) from the ore to create an intermediate MREC precipitate. The residue will be washed with water to recover residual reagents and REE content, prior to returning to the mining pits for later rehabilitation uses.

The MREC precipitate will be further processed to upgrade the concentration of the REE via membrane technology to produce an enriched REE product. The clean water from the membrane filter will be recycled back to the heaps for washing, while excess water will be processed to recover any reagents and residual REE contents.

Site infrastructure

The Makuutu site is situated just roughly 10km from Highway 109, a paved road that links Kampala to Kenya and the Port of Mombasa. Additionally, all-weather access roads connecting the site to the nearby sealed bitumen highway are already in place.

The project will receive its power supply from hydroelectric sources, which are readily accessible through a 132kV power transmission corridor that passes directly through the project area.

Water required for the project will be obtained through rainwater harvesting at the Makuutu project site.

Contractors involved

GJ Exploration has helped in the geological management and studies for the project. Benzu Minerals was responsible for the technical field services.

Environmental Plus, JBN Consults and Planners and Atacama Consulting conducted the environmental and social impact study for the project.

Metallurgical test works were conducted by ALS Metallurgy, Australian Nuclear Science and Technology Organisation, Bureau Veritas Minerals, SGS Lakefield, HudroGeoSense and Ultramet.

MinAssist was responsible for mineral stimulation modelling and process flowsheet design. Mineral resource estimation was done by Cube Consulting, a company based in Western Australia. The membrane plant design was provided by Eco Technol.

Mine planning was provided by Kalem Group, while Uganda-based mining services company, ADT Africa conducted the mine operating estimation.

Mincore, an Australian engineering, procurement and construction contractor, was responsible for process plant design, capital estimation and operations estimation.

Engineering services provider, DRA Global has been appointed to support the future development of the project.