The Lola graphite project is a high-grade graphite mine under development in the Republic of Guinea, Africa.

SRG Mining (formerly SRG Graphite) fully owns the project through its subsidiary Sama Resource Guinée.

The Government of Guinea granted environmental approval for the project in April 2019. The feasibility study (FS) for the project commenced in September 2018 and completed in July 2019.

The project is expected to produce an average of 54,600t of graphite flakes a year over its anticipated mine life of 29 years.

Lola graphite project location, geology, and mineralisation

The Lola graphite project is located near Lola, the Republic of Guinea. It hosts near-surface mineralisation over a strike length of 8.7km at an average width of 370m.

Initial surface of the deposit is well weathered (lateralised), which separates the graphite flakes from the silicate gangue. This will facilitate the grinding and recovery of large and jumbo flakes.

The deposit mainly hosts saprolite surface mineralisation, which extends into the fresh rock bed. Most of the mineralisation continues at depth of more than 30m within the non-weathered sheared gneiss. A large amount of mineralisation is also identified at surface over the entire strike length, with surface sample grades estimated to range up to 20% graphitic carbon (Cg).

Lola graphite project reserves

The proven and probable reserves of the Lola graphite project are estimated to be 42 million tonnes (Mt), grading 4.17% Cg.

Mining at Lola

SRG Graphite proposes to employ conventional open-pit mining methods, involving articulated haul trucks and loading shovels, at the Lola graphite project. The current mine plan envisages the extraction of mineral resources within the north, central, and south areas.

The recovered ore will be loaded onto haul trucks and sent to a primary crusher while the waste rock will be diverted to a dump.

Ore processing at Lola graphite project

The project will use a conventional flotation process to treat the mined ore to produce 73.1% of graphite grading 95.4% Cg. The production is expected to reach 84.2% with the addition of fresh rock.

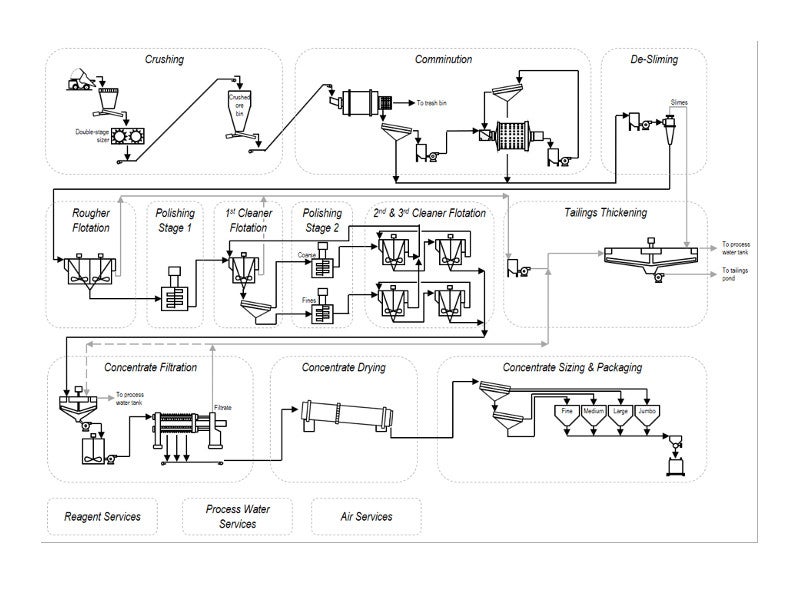

Run-of-mine (ROM) ore will be subject to two-stage crushing, following which it will be discharged to the concentrator through a belt conveyor. The material will then undergo scrubbing and grinding, rougher flotation, polishing, and three-stage cleaner flotation.

Graphite concentrates from the cleaner flotation banks will be pumped to the concentrate thickener. Underflow from the thickener will be pumped to the final graphite concentrate holding tank before being conveyed to the pressure filtration circuit. The thickener overflow will be sent to the process water tank for recycling the water.

Featuring a vertical plate pressure filter, the concentrate filtration circuit produces a graphite product filter cake containing 25% moisture. The cake will then be loaded onto a conveyor by gravity and taken to the dryer with the help of a hopper and a screw conveyor.

The concentrate will be dried to reduce the moisture content to 0.5% before being screened and packed into bags for shipment.

The processing plant will produce graphite concentrate in four standard-size fractions including +48 mesh, -48+80 mesh, -80+100 mesh, and -100 mesh.

Infrastructure

The Lola graphite project is situated close to the existing Highway N2, which connects Lola to Conakry, the capital of Guinea. A new 500m-long and 6m-wide road will be constructed off Highway N2 to connect the site.

Electricity for the Lola graphite project will be supplied by three 2GW heavy fuel oil generators.

The produced tailings will be stored in three tailings sites sequentially through the life of the project.

Other facilities include ancillary buildings and facilities such as maintenance garage and storage, administration and mine office areas, and an emergency concentrate warehouse.

Contractors involved

DRA/Met-Chem, a subsidiary of DRA Americas, and a group of consultants prepared the project feasibility study report. Other consultants involved in the FS preparation include Epoch Resources, BBA, Sahara Natural Resources, MDEng, SGS Canada, CCIC, and Jenike & Johanson.

SRG prepared the environmental study report in association with EEM Sustainable Management, Sylvatrop Consulting, and Guinée Environment Services. The resettlement action plan was prepared in partnership with Giovannetti Consultant.

Mine Design Engineering conducted the mine geotechnical fieldwork for the project while Sahara Natural Resources and DRA carried out the civil geotechnical fieldwork.

The on-site team of the Lola laboratory were trained by SOUTEX, a mineral processing consultancy firm in Quebec, Canada.