Voestalpine has been granted a patent for a process to produce a coated electrical steel strip. The method involves applying a pretreatment layer of specific thickness, followed by an insulating lacquer layer without deliberate drying or crosslinking in between. The pretreatment layer consists of specific components in defined proportions. GlobalData’s report on Voestalpine gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Voestalpine, Tunnel Boring Machines was a key innovation area identified from patents. Voestalpine's grant share as of May 2024 was 69%. Grant share is based on the ratio of number of grants to total number of patents.

Process for producing coated electrical steel strip

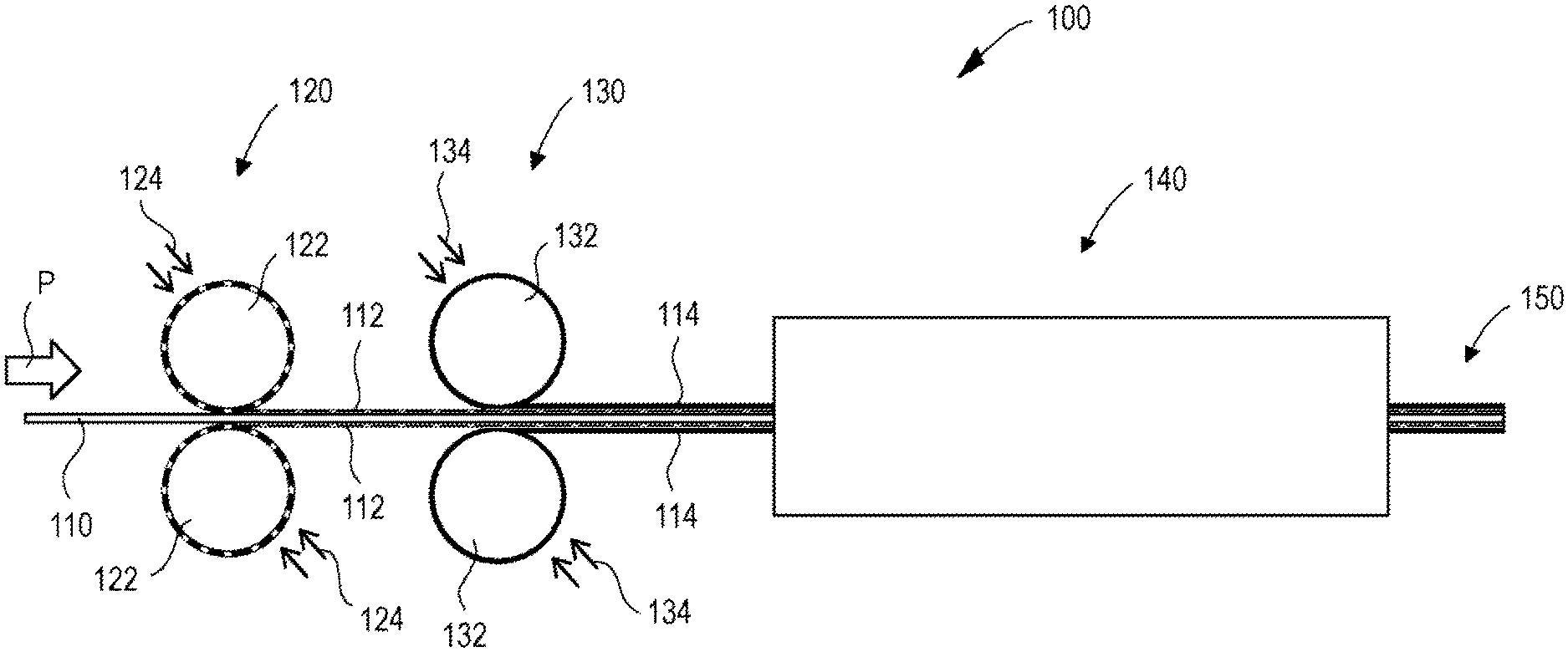

A recently granted patent (Publication Number: US11998946B2) discloses a process for producing a coated electrical steel strip. The process involves applying a pretreatment layer on one side of a rolled electrical steel strip, with the layer thickness ranging from 10 nm to 100 nm. Following this, an insulating lacquer layer is coated over the pretreatment layer using roll application without deliberate drying or crosslinking of the pretreatment layer. The pretreatment layer consists of polyvinyl alcohol, phosphoric acid, and a solvent or water balance. Additionally, the insulating lacquer layer is a baking lacquer containing epoxy resin and a latent hardener to convert thermoplastic into thermoset.

Furthermore, the patent details various aspects of the process, including the layer thickness of the pretreatment layer, application methods, and additional layers on the opposite side of the steel strip. The thickness of the insulating lacquer layer ranges from 1 µm to 12 µm, with options for thinner layers. The process also includes cleaning the steel strip before applying the pretreatment layer and utilizing specific percentages of polyvinyl alcohol and phosphoric acid in the pretreatment layer. Overall, the patented process aims to efficiently produce a coated electrical steel strip with precise layer compositions and thicknesses to enhance its electrical properties and performance in various applications.

To know more about GlobalData’s detailed insights on Voestalpine, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.