Hyundai Steel has patented a method for manufacturing an aluminum-coated blank, involving laser beam irradiation to join aluminum-coated steel sheets. The process includes specific parameters like pattern angle, laser beam frequency, power, and coating weight. The patented technology ensures a strong joint with precise composition. GlobalData’s report on Hyundai Steel gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Hyundai Steel, Hydrogen fuel cells was a key innovation area identified from patents. Hyundai Steel's grant share as of May 2024 was 64%. Grant share is based on the ratio of number of grants to total number of patents.

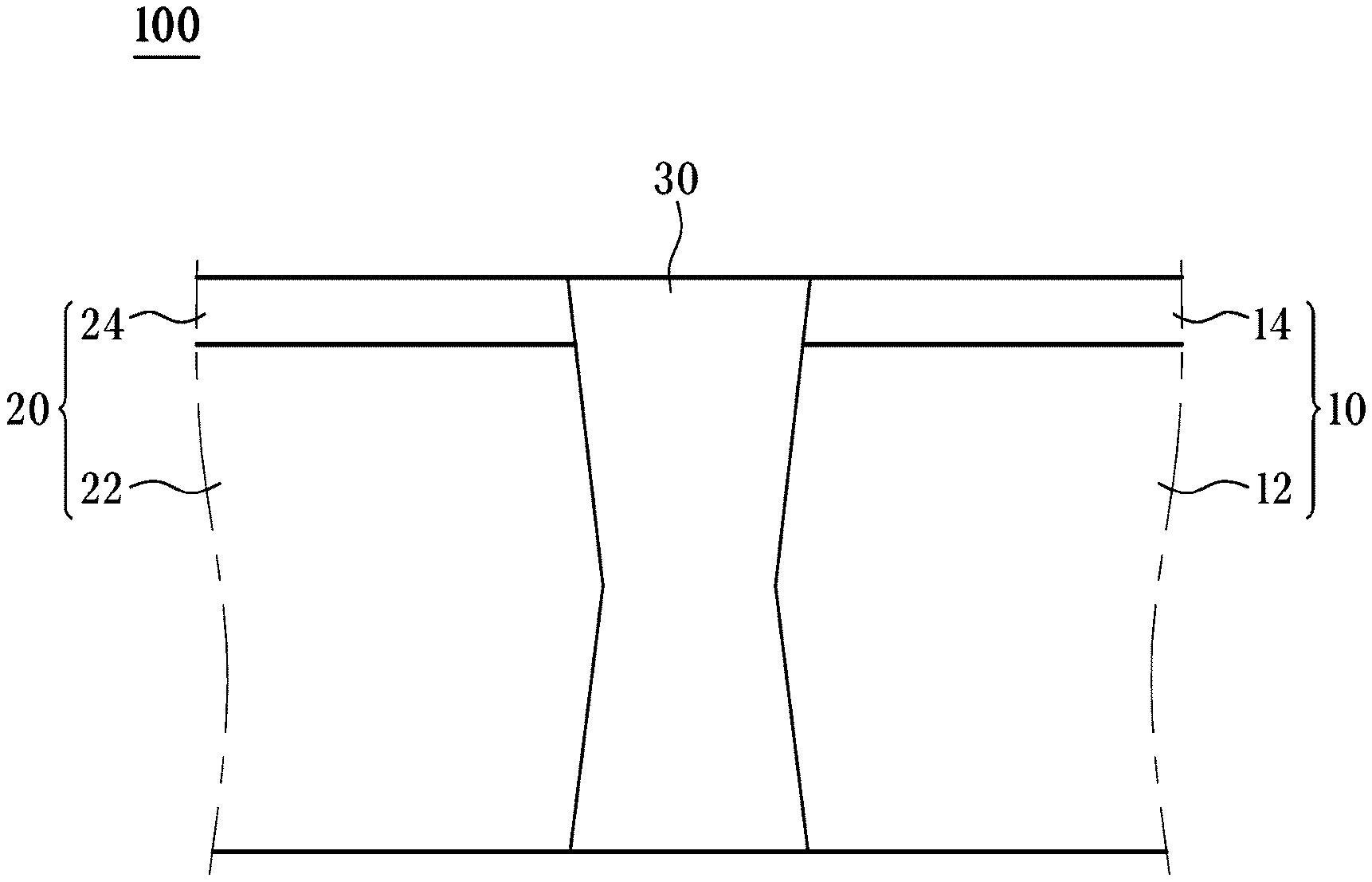

Laser welding method for aluminum-coated steel sheets

The granted patent (Publication Number: US11958131B2) discloses a method for manufacturing an aluminum-coated blank. The method involves aligning two or more aluminum-coated steel sheets, providing a filler wire, and melting the facing portions of the sheets and filler wire using laser beam irradiation to form a joint. The joint is formed at a specific pattern angle ranging from about 45° to less than about 90°, with the laser beam having a frequency of about 100 to 1,500 Hz and a power of about 1 to 20 kW. The joint formation speed, laser beam radius, and composition of the aluminum-coated steel sheets are also specified in the claims.

Furthermore, the method includes the use of a filler wire that may contain manganese (Mn) and the formation of the pattern angle through the movement of the coated steel sheets and the laser head during the laser beam irradiation. The composition of the joint is defined by the presence of aluminum (Al) within a specific range and the absence of ferrite formation at high temperatures. The relationship between the frequency of the laser beam, the radius of the laser beam, and the speed at which the joint is formed is represented by a specific equation, ensuring the quality and integrity of the joint formed. Overall, the patent outlines a detailed and precise method for manufacturing aluminum-coated blanks using laser beam technology, emphasizing specific parameters and compositions to achieve the desired results.

To know more about GlobalData’s detailed insights on Hyundai Steel, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.