BBE Projects Releases Catalogue of Mine Ventilation and Refrigeration Projects

BBE Projects delivers complete turnkey designed, engineered and constructed projects in the fields of mine ventilation, refrigeration and cooling.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Bluhm Burton Engineering (BBE) is a team of experienced professional consulting engineers who are leaders in mine ventilation, refrigeration and cooling practices; measurement and control of underground pollutants (dust, diesel, methane, radiation etc); energy optimisation and energy recovery, computer modelling and software for ventilation and cooling networks.

BBE provide a comprehensive suite of services including:

BBE’s experience includes a wide range of mining methods, in a various ore bodies, in several countries including the following:

BBE provide a comprehensive service from conceptual investigations, through technical feasibility studies and the analysis of alternative ventilation and cooling distribution systems, to selection of the optimum system, preparation of detailed engineering design specifications, estimating and project execution and management, for existing mines and new projects.

BBE strive for energy efficient systems making optimum use of energy recovery devices (Pelton wheel turbines, three-chamber pipe feeders, hydropower etc)

BBE have considerable experience in the control of underground pollutants and in fire engineering, having contributed significantly to numerous research and investigation programmes around flammability of materials, fire engineering, fire fighting techniques and escape and rescue strategies.

BBE are the driving force and co-developers of customised software for the analysis of mine ventilation, contaminant tracking, refrigeration and cooling networks (e.g. VUMA, Environ, Chiller, Coolflow) with particularly full thermodynamic solutions. The most modern package, VUMA, comprises a suite of modules that determine air flow, pollutant levels and temperature distribution throughout the ventilation circuit and cooling network, all displayed in 3D full colour graphics. The latest addition will interface with live monitoring of underground conditions, with the option for remote control of ventilation ‘on demand’. BBE also perform full CFD (Computational Fluid Dynamics) analysis of airflow in drifts for optimised (capex/opex) designs.

BBE senior engineers have over 100 years of experience in mining research, including underground field studies, in the fields of mine ventilation, cooling practices, pollutant control, mine water quality, fire engineering and cooling practices. BBE engineers made significant contributions to numerous research programmes in the South African mining industry (e.g. SIMRAC, SIMCOL, SIMGEN, SIMOT, SIMHEALTH, DeepMine, FutureMine)

BBE engineers have contributed significantly to state-of-art technology, evaluation of novel cooling systems (e.g. recirculation, ice and hydropower) and to analysing the effects of novel mining methods. BBE holds a number of patents related to novel cooling systems and has an on-going programme of implementation and energy and cost reductions.

BBE engineers regularly conduct training courses and workshops for mines, mining houses, and professional societies and also lecture at universities. BBE is registered with ECSA for the on-going development of in-house professionals.

(Images by kind permission of clients.)

BBE Projects delivers complete turnkey designed, engineered and constructed projects in the fields of mine ventilation, refrigeration and cooling.

Download BBE's free brochure for information about the company's services and turnkey projects in mine ventilation and cooling systems.

BBE Consulting consists of a team of experienced professional consulting engineers and practitioners in mine ventilation, refrigeration and cooling practices.

BBEnergy has completed projects across a broad range of applications in the mining industry to reduce energy consumption, including refrigeration, mine ventilation, water pumping, compressed air control, solar PVs and concentrated solar thermal plants.

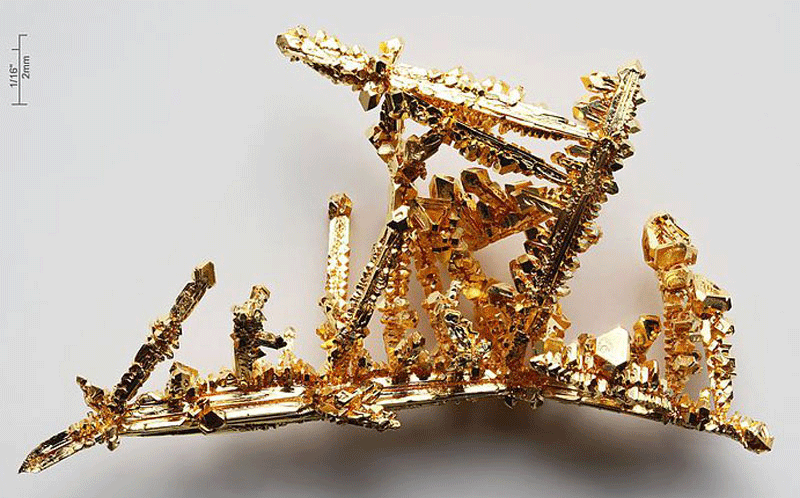

The Nyanzaga gold project, located in the Lake Victoria Goldfields of Tanzania, is being developed by OreCorp.

GoldQuest Mining's 100%-owned Romero Gold-Copper Project is located within the Tireo property, on the island of Hispaniola, Province of San Juan, Dominican Republic.

The Wheeler River Uranium Project is located approximately 35km north-northeast of the Key Lake mill, and 35km southwest of the McArthur River uranium mine, within the eastern edge of the Athabasca Basin, in northern Saskatchewan, Canada.

Our visit to China provided a valuable insight into a number of ventilation and cooling challenges and initiated exploratory discussions with several contacts in coal, gold and copper mines/groups. There appears to be a genuine enthusiasm in the larger mining groups to tackle the problems and a r

On 18 September 2006 VUMA version 3.0 was launched at a function held at the Kloof mine Country club. The features of the improved version 3.0 were demonstrated and new ideas for future upgrades were discussed. A new dynamic website for VUMA has also been launched, from where updates, demonstrati

On his arrival at BBE in August 2006, Mr Willie Kruger, Safety Manager, assisted with the finalisation of BBE's Safety, Health and Environmental Policy. This policy will form the basis of BBE's SHE Management System for all major contracts and can be viewed on the BBE website.

No 16 Shaft BBE has been awarded a large turnkey contract to design, construct and commission a 16MW refrigeration plant and air cooler system at the mine's No. 16 Shaft. The installation will consist of surface bulk air cooling spray chamber and fans, refrigeration equipment, con

The presentation was made at the AGM of the Mine Ventilation Society of South Africa on 23 June 2006. The paper was published in the October/December 2005 issue of the Journal of the MVS, [Vol. 58, No. 4]. Concepts discussed in the paper were presented at the Tenth U.S./North American Min

In May 2005, BBE were awarded the turnkey contract to build two 18 MW(R) bulk air coolers and associated refrigeration plant at AngloGold Ashanti’s Obuasi Mine in Ghana on a turnkey basis. Earthworks at the first site at Kwesi Mensah Shaft began immediately; civil construction was completed in

Eskom Demand Side Management [DSM] have awarded BBE a turnkey contract to design, install and commission a large ice thermal storage system at AngloGold Ashanti's Mponeng Mine, located near Carletonville, South Africa. The system will significantly reduce electrical costs by melting ice to prov

VUMA-network 3.0 represents a streamlined, user-friendly and extremely robust software product with significant new developments and improvements compared to version 2.5. Network construction is now more rapid due to added functionality in the 2-D graphics interface. Navigating and viewing the ne

BBE is currently involved in three separate refrigeration projects for Australian mines. The projects are at Rosebery Mine (Zinifex) in Western Tasmania, Argyle Diamond Mine (Rio Tinto) and Granites Gold Mine (Newmont) in Western Australia. BBE has an EPCM contract with Rosebery for the install