TRUST ITM® Mobile Kit – Real-time Brake Monitoring for Scrapers

The TMK system uses magnetic sensors to monitor brake drum temperatures in real time, providing immediate alerts for irregularities.

ITM Group is an international premium brand designer, manufacturer, and service provider of undercarriage components and complete undercarriage solutions, covering virtually the entire range of modern crawler machine applications in the construction, mining, utility, forestry, road building, and agricultural industries.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

ITM Group is an international premium brand designer, manufacturer, and service provider of undercarriage components and complete undercarriage solutions, covering virtually the entire range of modern crawler machine applications in the construction, mining, utility, forestry, road building, and agricultural industries.

ITM has a comprehensive range of undercarriage parts and complete customized solutions for several industry segments. Our extensive product range includes track chains and shoes, rollers, sprockets and segments, idlers, and tension groups.

As a pioneer in undercarriage sensor technology ITM has developed TRUST ITM®, an innovative tracking system to monitor undercarriage, maximise uptime, improve productivity and safety in the fi eld and empower autonomous-drive equipment. ITM carefully thinks how its actions, decisions and plans can minimise the impact on the environment

The production capacity in its facilities are located in Italy, Germany, Spain, USA, Brazil, China, Australia and India. A Global Top-Quality Partner with cutting-edge solutions for several industrial sectors: mining, construction, paving, agriculture, forestry, marine and others specific applications.

The headquarters of the Group, Italtractor ITM, founded in 1957 is based in Valsamoggia, Bologna, Italy. ITM, with over 1.600 professionals and engineers worldwide, operates through a global service network, dealers and distributors. Italtractor ITM S.p.A. is a Titan international Inc. Company.

ITM always places the customer at the centre, offering an integrated ecosystem of solutions and services that accompany the entire undercarriage lifecycle. ITM turns data into value and solutions into tangible results to guarantee reliability, sustainability and long-term value. ITM’s undercarriage components and complete frame solutions are designed to fit a variety of machines and improve their performance. ITM is committed to ensuring its products always meet the highest standards to fulfil the severe requirements of the mining industry, constantly introducing new and innovative solutions while maintaining the lowest possible hourly operating costs.

ITM’s Special Projects team provides turnkey solutions that combine design capabilities with our in-house workshop, covering all production processes and test phases for the development of dedicated solutions. Our engineering experts are fully capable of creating unique tailored solutions to meet our customers’ requirements. Thanks to our seamless in-house production, which allows us to handle every stage of the manufacturing process, we can provide one-stop solutions for any undercarriage needs.

The ITM Group has its own foundry and forging facilities that produce a diverse range of cast products, ensuring quality control and flexibility in material selection, allowing us to create undercarriage components that meet the highest standards of durability and reliability. Based in Germany, our assembly teams ensure that each component is fitted with precision, adhering to the highest standards of quality. From our facility to customers’ application site, we manage logistics perfectly, ensuring timely delivery of any type of undercarriage. ITM has completed over 3,000 international tailor-made projects, all highly competitive and unique in style.

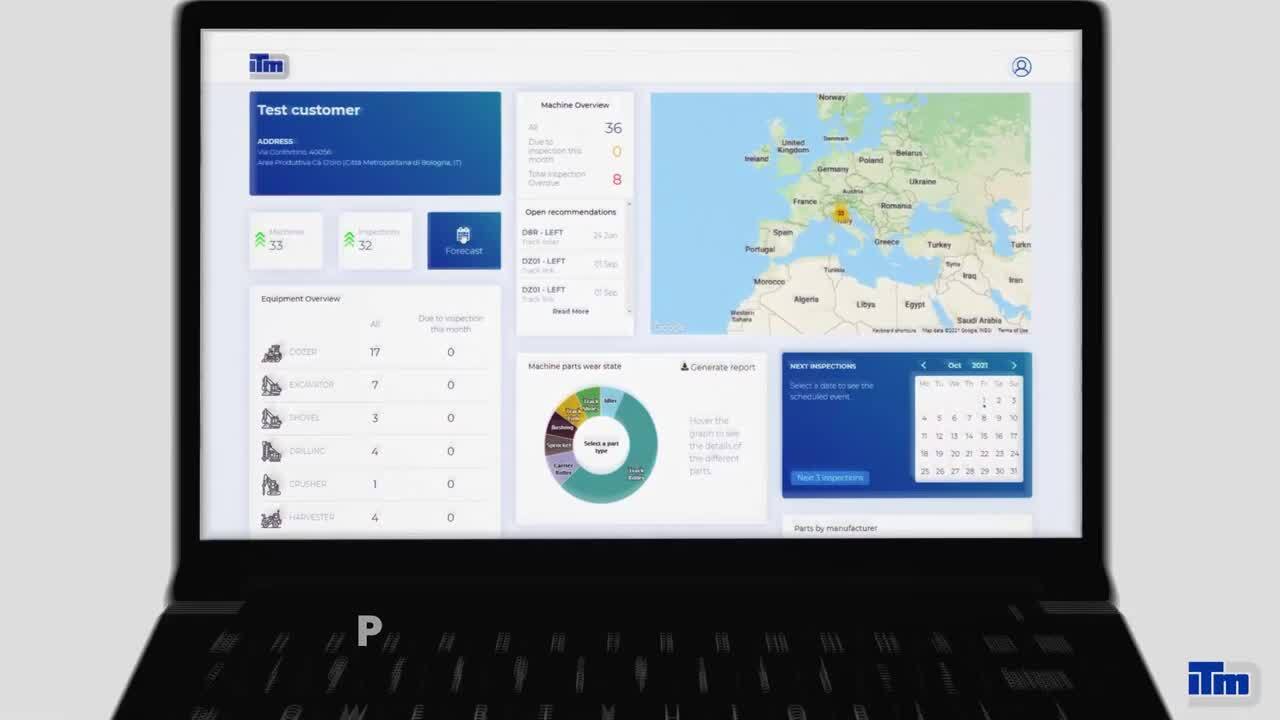

In addition to its traditional products, ITM is leading the transformation of the industry with TRUST ITM®, an innovative monitoring system designed to remotely control the status of undercarriages. This system not only enhances self-driving machinery, but also maximizes uptime, improving operational efficiency, productivity and operator safety. Using wireless sensors and IoT technology, TRUST ITM® delivers key component parameters in real time through the TrackAdvice® platform, the proprietary software developed by ITM for optimal undercarriage management. TrackAdvice® analyzes component wear status, facilitates maintenance planning and optimizes replacement scheduling.

With a global presence, ITM supports customers at every stage of the undercarriage lifecycle, offering a complete range of services designed to ensure high performance, long-lasting durability and maximum operational efficiency. From design to field technical support, our team of experts is always by your side, anticipating potential issues and intervening promptly with preventive solutions. Thanks to our experience, technology and ongoing support, ITM helps to maximise uptime, enhance safety and reduce the cost of ownership.

The environment is a continuous focus for the ITM Group and relevant factors are regularly monitored, ensuring accurate energy, waste and water management data disclosures. The quality of the product and the commitment to reduce waste, field contamination and, most importantly, the extension of product life, is one of the main focuses of ITM’s strategy and innovation.

The TMK system uses magnetic sensors to monitor brake drum temperatures in real time, providing immediate alerts for irregularities.

In Kazakhstan’s iron ore mining sector, the EX5600 excavators were equipped with the TRUST ITM® Mobile Kit (TMK) to monitor hydraulic systems in real time.

This case study from a coal mine in the Philippines showcases the use of the TRUST ITM® Mobile Kit (TMK) on bucket wheel excavators to monitor planetary gearbox temperatures. Customised magnetic sensors provide real-time, in-cabin alerts and remote monitoring capabilities.

A D11 operating in a sand mine was equipped with TRUST ITM® sensorised rollers.

This success story from an Australian iron ore mine details how the TRUST ITM® Mobile Kit (TMK) improved the performance of EX3600 excavators.

Valsamoggia, Bologna, March 26, 2025 - ITM Group, a leading innovator in undercarriage sensor technology and a trusted supplier in the industry, will participate in BAUMA 2025, the leading trade fair for construction and mining equipment, to be held in Munich from April 7-13. ITM Group will present its latest innovations at Hall A5, booth 137.

Pioneers in undercarriage sensor technology and leading providers of integrated solutions: ITM offers comprehensive solutions to address specific customer challenges through a combination of expertise, technologies, and tailored services that respond

The Group has an ongoing Research and Development program managed by dedicated engineering teams that seek to improve the quality of the existing products, develop solutions for new equipment models and applications.

TrackAdvice® is an open system for monitoring all types of machines, regardless of brand, by combining data from manual inspections and sensorised components on a single platform, enabling advanced maintenance planning.

The environment is a continuous focus for the ITM Group and relevant factors are regularly monitored, ensuring accurate energy, waste and water management data disclosures.