Improved classification with Cavex DE Hydrocylones for mill circuit, coarse particle flotation, and tailings applications.

J J Hanhiniemi, J Heo, N Weerasekara, E Wang, H Thanasekaran6 and A Kilcullen

Weir has over 150 years of experience of powering progress in the world’s major industries.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Weir has over 150 years of experience of powering progress in the world’s major industries. By combining our market-leading, trusted brands including ESCO®, WARMAN®, ENDURON®, GEHO®, CAVEX®, LINATEX®, NEXT and MOTION METRICSTM, we are delivering transformational flowsheets that help our customers move less rock, use less energy, use water wisely and create less waste.

At Weir, all of our products are backed by our unrivalled global support network that spans more than 60 countries world-wide.

Weir is a mining technology company. Our technologies help customers in mining and similar industries operate with the highest productivity and lowest environmental impact.

Customers rely on our solutions and our service to keep their mission-critical operations running efficiently and drive their sustainability footprint down. We are located close to them, never more than 200km away, wherever they are in the world. And with our integrated network of technology hubs, manufacturing operations and local service centres, it is Weir technology, Weir brands and Weir people that are at the heart of the global mining industry.

We are a global family of c.12,000 people working across more than 50 countries across the globe focused on making mining smart, efficient and sustainable today, and for the future.

Enabling the sustainable and efficient delivery of the natural resources essential to create a better future for our world.

Metals power the world. They are the backbone of our modern society. And metals are vital for a sustainable future too – copper for decarbonising and electrifying transport; lithium, nickel and cobalt for batteries and energy storage; iron and aluminium for the infrastructure to support widespread electrification.

Today, much of the metal used each year is extracted from our earth, and that is set to continue for decades to come. That’s why our customers in the mining industry are transforming to more sustainable practices and striving for Net Zero emissions.

And that presents an incredible challenge. How to get more of those metals from less. Less water, less waste, less energy and less CO2.

Here’s where Weir comes in. Our technologies are the beating heart of critical processes in mines across the globe. And we have made it our purpose to ensure the sustainable and efficient supply of the vital natural resources essential for a better world today, and for the future.

How? By challenging the norm with expertise in innovative engineering technology. Using our 150 years of experience of powering progress in the world’s major industries; by adapting and seeing things differently. Today our expertise and experience have never been more relevant as we help our mining customers transform, with technology to achieve the productivity and sustainability goals needed for us all to enjoy a low carbon future.

Our planet’s future depends on the transition to renewable energy, and that transition can only happen with the metals and minerals our mining customers deliver.

Every mine is different. Delivering innovative mining technology solutions demands a combination of deep customer insight, world class engineering and materials science, enabled by intelligent automation.

No one serves more mines than Weir. Working in close partnership with our customers, we help them to move less rock, use less energy, use water wisely and create less waste – accelerating the path to smart, efficient and sustainable mining.

The world is looking to our mining customers to provide many of the natural resources needed to support the transition to a net zero economy.

At the same time our customers are taking steps to reduce their impact on communities and the environment by making their operations more sustainable. Their challenges are our challenges, and we are ready to support them.

With our world class engineering expertise, we work in partnership with our customers to solve their toughest operating challenges safely, efficiently and sustainably, helping to provide the essential resources needed by a growing world.

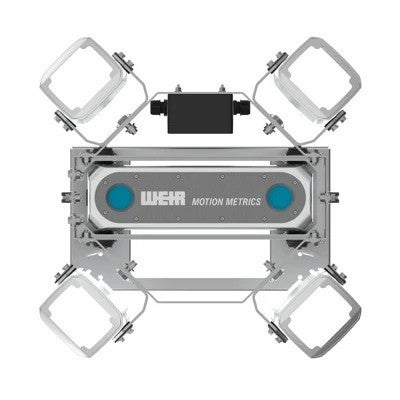

Weir’s NEXT Intelligent Solutions deliver you the knowledge you need today to reach peak performance mining.

You’ve trusted us for over 150 years to deliver highly engineered solutions. Now we want to help you unlock even more potential.

Weir’s NEXT Intelligent Solutions provide a deep understanding of your mining operations through digitally empowered equipment and systems. Utilise real-time data to make informed decisions, boost operational efficiency with predictive monitoring, and embrace cutting-edge automation. Take your performance to the next level.

Weir’s NEXT Intelligent Solutions deliver you the knowledge you need today to reach peak performance mining.

You’ve trusted us for over 150 years to deliver highly engineered solutions. Now we want to help you unlock even more potential.

Weir’s NEXT Intelligent Solutions provide a deep understanding of your mining operations through digitally empowered equipment and systems.

Utilise real-time data to make informed decisions, boost operational efficiency with predictive monitoring, and embrace cutting-edge automation.

Take your performance to the next level.

J J Hanhiniemi, J Heo, N Weerasekara, E Wang, H Thanasekaran6 and A Kilcullen

The Iron Bridge project is a magnetite mine in Western Australia. It is owned by a joint venture (JV) between FMG Fortescue (69%) and Formosa Steel (31%).

Exploring for barytes in Santa Cruz province, Argentina’s geological survey identified gold mineralisation at Cerro Vang

Weir, a global leader in mining technology, today announces the launch of its latest report, Untapped: Mining’s opportunity to unlock value through strategic water management and innovative technology.

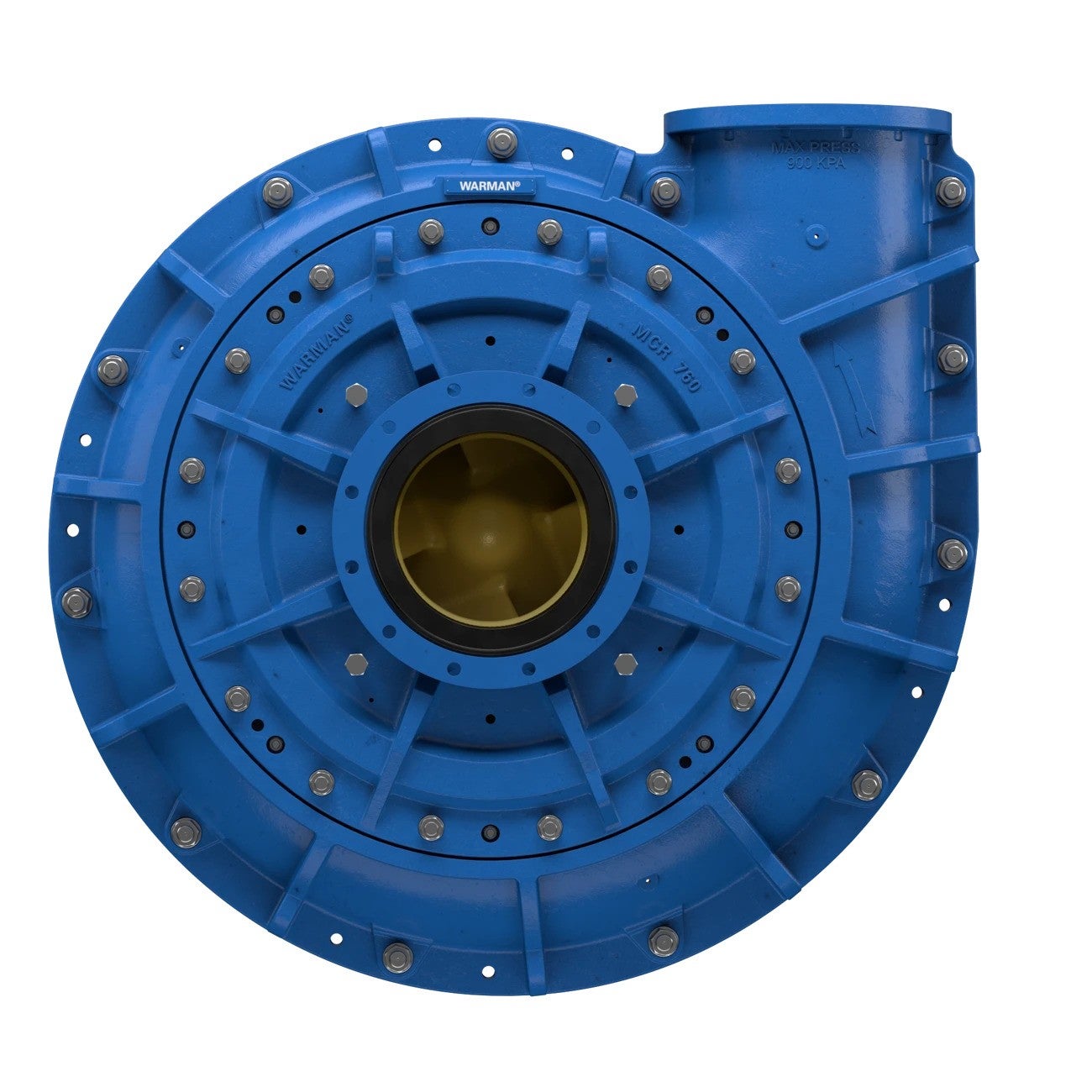

Weir, a mining technology company, proudly marks the 60th anniversary of its iconic WARMAN® AH® horizontal slurry pump.

Weir, a mining technology company, has entered into a strategic collaboration agreement with Viking Analytics, a Swedish-based company specialising in AI-powered vibration analysis and condition monitoring for smarter predictive maintenance.

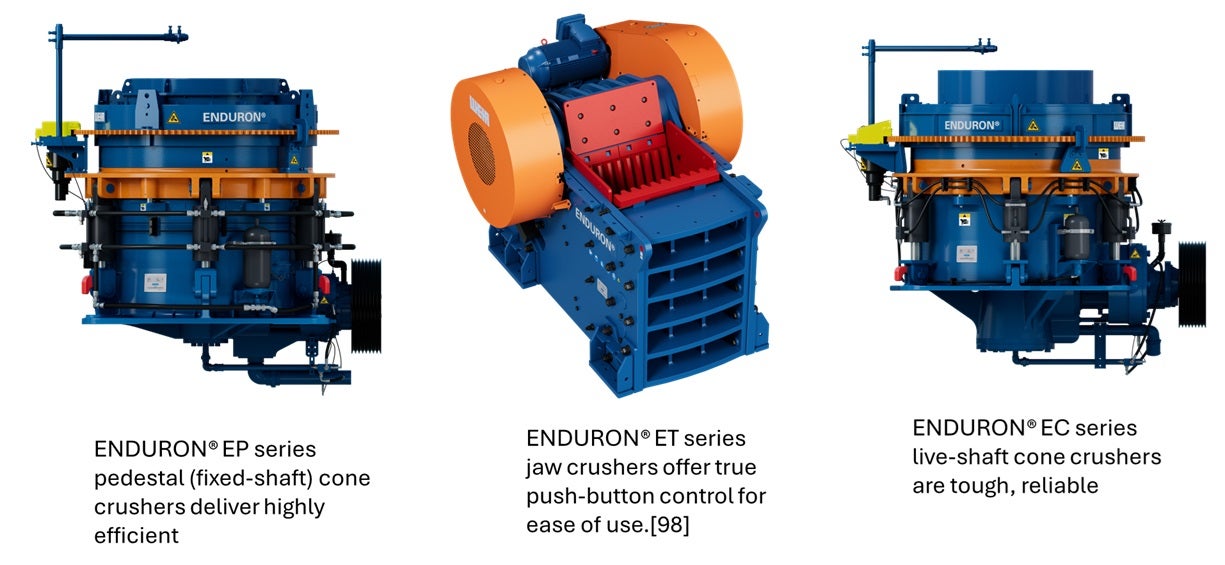

Weir, a global leader in mining technology, has launched a new range of ENDURON® jaw and cone crushers, developed in close collaboration with customers to address their most pressing operational challenges.

Weir, a mining technology company, has redesigned its market-leading heavy-duty submersible slurry pump to deliver reliable performance in the harshest slurry environments.

Weir has entered into a strategic cooperation agreement with MINEXXT, Inc., to strengthen its global leadership in thickened and paste tailings solutions.

In his new role, Mick will focus on expanding Weir’s regional presence, strengthening customer partnerships, and ensuring consistent delivery of high-performance solutions across the full product portfolio.

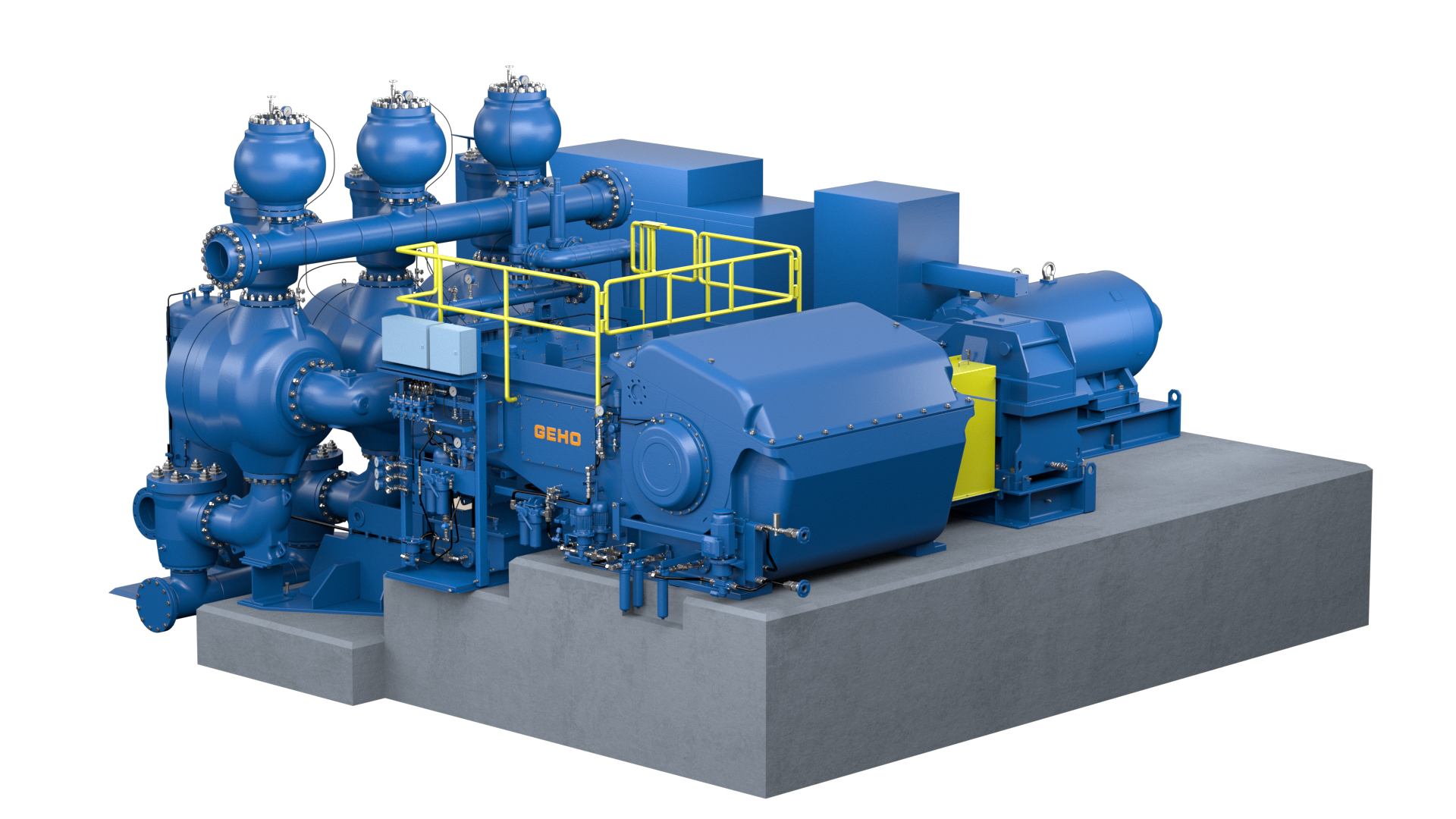

Order including GEHO®positive displacement pumps, WARMAN® centrifugal pumps, and ancillary equipment to be booked in Q2

The Weir Group PLC (“Weir”), a leading engineering and mining technology company and CiDRA Minerals Processing Inc. (“CiDRA”), a leader in mineral processing technologies, announce that they have signed a global collaboration agreement alongside a strategic investment by Weir in CiDRA’s mining business.

Weir, a global leader in mining technology, has been awarded the contract to supply a large ø2.4m x 2.25m Enduron® HPGR (high-pressure grinding rolls) for De Grey Mining’s flagship Hemi Gold Project in the Pilbara region in Western Australia.

Weir, a global leader in innovative mining technology, has launched the all-new ENDURON® Orbital range of vibrating screens.

The full order, which includes a range of both WARMAN® slurry pumps and CAVEX® hydrocyclones, will be recognised in Q3 2024.

Melbourne, Australia – Weir, a global leader in mining technology, has officially opened its new Port Hedland Service Centre, strategically located in the heart of the Pilbara region, Western Australia.

The first call-off order of £26m, which includes both ENDURON® large format High Pressure Grinding Rolls (HPGR) and wet screens, will be recognised in Q3 with the remaining orders booked later in 2024 and early 2025.

Weir is an innovative, end-to-end solutions provider focused on accelerating sustainable mining. Exhibiting at this year’s MINExpo, in the Central Hall Booth #8833, Weir will be showcasing its marketing-leading brands and unveiling a range of new innovative technologies and solutions.

Weir Group PLC (Weir), a global mining technology leader, has been awarded contracts to supply its market-leading WARMAN® slurry pumps and CAVEX® hydrocyclones to Teck’s Highland Valley Copper (HVC) Mine Life Extension (MLE) project in Canada.

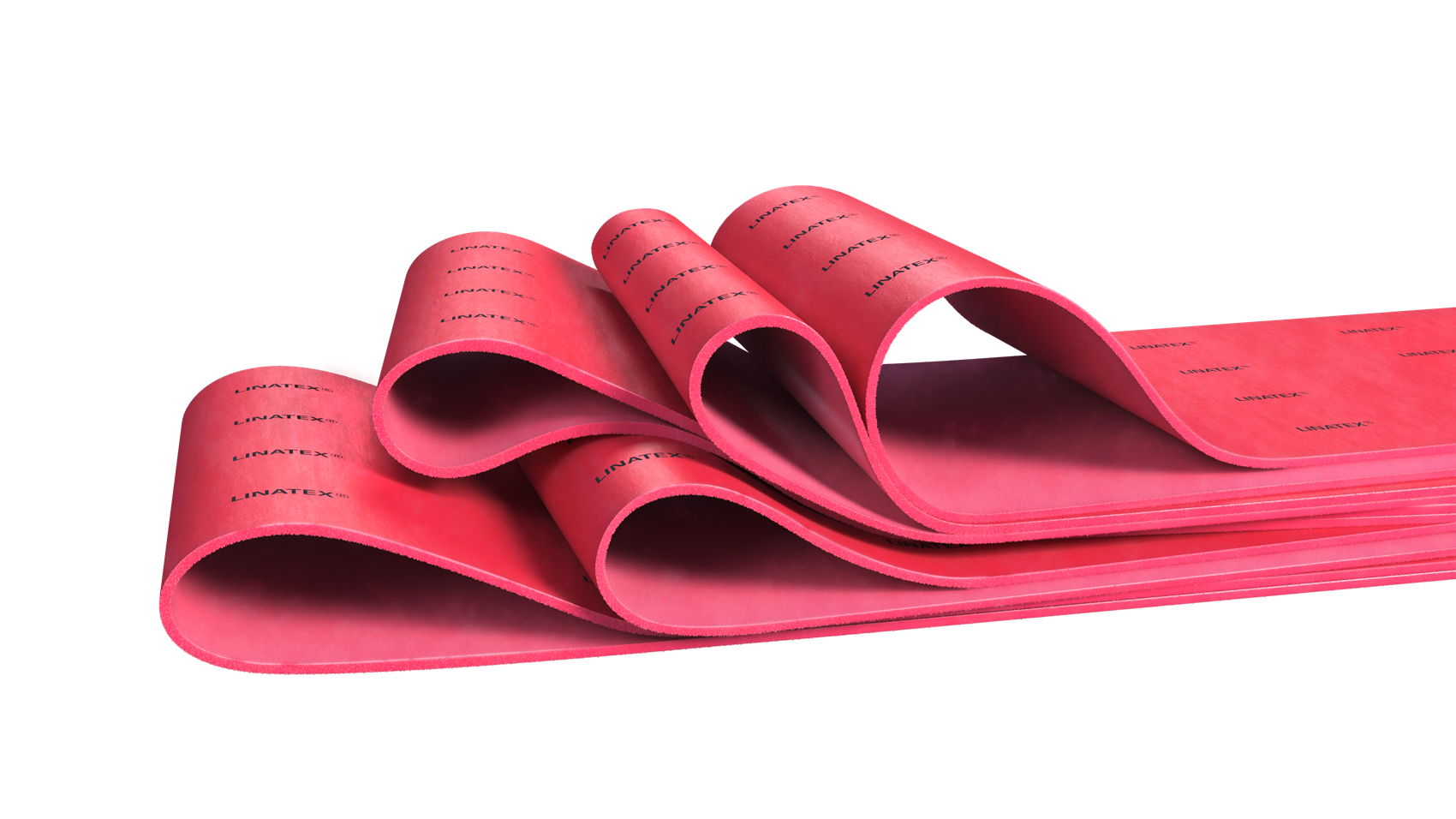

Weir, the global leader in technology driven mining solutions and sole manufacturer of Linatex® premium rubber, has introduced new branding to their iconic red rubber. Linatex® premium rubber is renowned for its unparalleled wear life and total cost of ownership benefits, this new enhancement is a definitive stand against imitators selling inferior red rubber products under the Linatex® name.

Cavex® hydrocyclones are renowned for their high efficiency and advanced separation capabilities.

The most trusted name in slurry pumps since 1938.

Surround yourself with next level knowledge.

Operation monitoring systems for mine-to-mill optimisation.

Linatex® premium rubber products have been protecting processing equipment in the mining, minerals, aggregate and general industry since 1923.

GEHO® positive displacement pumps are the industry's #1 choice to transport the most abrasive, corrosive and high temperature slurries, sludges and tailings over long distances.

Market-leading products for mining, construction and industrial applications

Efficient and innovative comminution solutions