Nanosilica Filled, Dual Curable Adhesive Offers Rapid Fixturing with LED Light

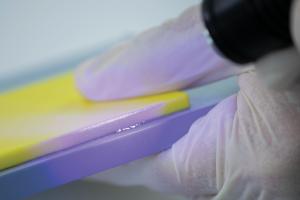

Master Bond LED422DC90 is a one component, nanosilica filled dual cure adhesive system engineered for high-speed fixturing and bonding of opaque substrates. This unique “side-bonding” capability allows for rapid polymerization up to 3-4 mm in depth by exposing the adhesive to 405 nm LED light from an angle. The cure is then completed by a secondary heat cure at 90-95°C for 30-45 minutes. This two-tiered curing process allows for the precise and rapid fixturing of heat-sensitive components.

LED422DC90 provides good dimensional stability and a relatively low coefficient of thermal expansion for a dual-cure LED product, at 30-40 x 10-6 in/in/°C. It is an optically clear material with a refractive index of 1.49, a Shore D hardness of 85-90, and an elongation of 1-3%. The system possesses a good strength profile, featuring a tensile strength of 6,000-7,000 psi, a tensile modulus of 475,000-575,000 psi, and a tensile lap shear strength for aluminum to aluminum of 800-900 psi.

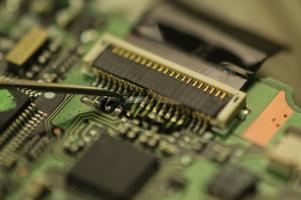

The system is a reliable electrical insulator with a volume resistivity greater than 1014 ohm-cm. It passes NASA low outgassing certifications and is designed for use in the electronics, optics, and aerospace industries. LED422DC90 bonds well to a variety of substrates, including plastics, glass, and metals, and is serviceable from -80°F to +350°F. This adhesive is available in EFD® syringes, ½ pint, pint, and quart containers.

For more information, please visit our product page.