Advanced High Performance Epoxy Adhesives Revolutionize Structural Bonding

Structural polymers offer distinct advantages over traditional fastening methods. In this whitepaper, we explore the cornerstones of successful structural bonding.

Master Bond is a leading manufacturer of high-performance adhesives, sealants, coatings, potting and encapsulation compounds for the assembly of mining equipment, transportation and automotive industry, including electric vehicles, batteries and more.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Master Bond is a leading manufacturer of high-performance adhesives, sealants, coatings, potting and encapsulation compounds for the assembly of mining equipment, transportation and automotive industry, including electric vehicles, batteries and more.

The company specialises in the production of one-part and two-part epoxies, silicones and UV/LED curing compounds, these materials feature outstanding performance properties that meet engineers’ specific application requirements. We have more than 3,000 formulations and have been in business since 1975.

These systems feature outstanding performance properties, including:

Performance properties can be adjusted to meet specific application requirements. Master Bond’s extensive product line includes compounds that comply with industry certifications.

Master Bond’s coatings offer protection against hostile conditions encountered in the mining process. Specific grades feature high hardness, which prevents degradation from severe chemical attacks, including splash, spills, immersion, friction, wear and a combination of impact and abrasion.

Corrosion mitigation properties on metallic substrates meet high standards to ensure the structural integrity of mining equipment and long-term reliable serviceability.

Master Bond’s metal-filled epoxy and elastomeric compounds have been used in such assemblies. Room temperature-curing, two-component epoxies have also been used in many sealing and gap filling applications.

Aluminium-filled compositions are employed for their good void filling capability, dimensional stability, low shrinkage and outstanding physical strength characteristics.

Master Bond products are formulated to the highest quality standards. Compliance testing has been conducted by American government authorities and established independent testing laboratories.

Our extensive product line includes a variety of compounds that pass stringent testing requirements. A partial list of these specifications is listed below:

Master Bond’s technical staff has decades of knowledge in solving application problems.

Every incoming inquiry is assigned to an experienced technical representative who will collaborate with you throughout the design, prototyping and manufacturing processes.

We pride ourselves on the provision of direct and personal support. Our approach to specific technical problems emphasizes simplicity of application and reproducibility of results.

Structural polymers offer distinct advantages over traditional fastening methods. In this whitepaper, we explore the cornerstones of successful structural bonding.

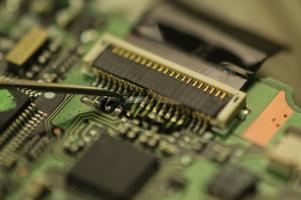

A study conducted at L’École Polytechnique Fédérale de Lausanne (EPFL) in Lausanne, Switzerland, investigated alternative materials for use in high temperature control electronics packaging. Master Bond Supreme 10HT was one of the adhesives tested in the study.

Master Bond LED422DC90 is a one component, nanosilica filled dual cure adhesive system engineered for high-speed fixturing and bonding of opaque substrates.

Master Bond EP29LPSPND-3 is a two component, non-drip epoxy compound with a paste consistency that can be used for bonding and sealing applications.

Master Bond Supreme 11AOHTLP is a two component epoxy featuring thermal conductivity and electrical insulation.

EP114 features excellent flow properties, with a mixed viscosity of 500-1,500 cps.

Master Bond Supreme 17HTND-2 is a toughened epoxy system for bonding and sealing applications. It is a true one component system, not premixed and frozen, with an unlimited working life at room temperature. Supreme 17HTND-2 is thermally stable, featuring a high glass transition temperature (Tg) of 410°F (210°C). It also meets NASA low outgassing specifications per ASTM E595 testing.

Master Bond EP21LVFL combines good flexibility with a solid strength profile. It is curable at room temperature with a long working life of 120-160 minutes at 75°F for a 100 gram batch and features a flowable initial mixed viscosity of 10,000-14,000 cps. This epoxy generates low exotherm making it suitable not only for bonding and coating, but also for sealing and potting applications.

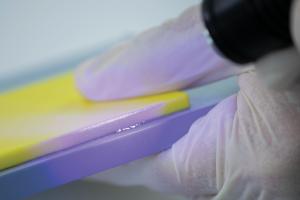

With a forgiving mix ratio of 100 to 40 by weight or 100 to 50 by volume, this paste consistency material can be easily applied with the use of a gun dispenser or spatula.

Master Bond EP21AC is a two part epoxy with a non-halogenated filler that is formulated for applications where arc resistance and flame retardancy are required.

Master Bond EP40TC is a two part epoxy system, designed for bonding, sealing and encapsulating applications where thermal conductivity and electrical insulation are required.

EP40ND meets Nasa's low outgassing specifications and has a high elongation of 80-90% at 75°F.

These adhesive systems were evaluated for their mechanical performance. Bonded surfaces were subjected to extreme high/low temperatures to determine their long-term durability.