SKF Cooper split spherical roller bearings

Faster, safer bearing exchange with SKF Cooper split spherical roller bearing

At a mine in Colorado, USA, the maintenance department performed a 9-day bearing exchange in just 4 days, well within limits of their 6-day stockpile. How? By installing an SKF Cooper split spherical roller bearing instead of a standard bearing.

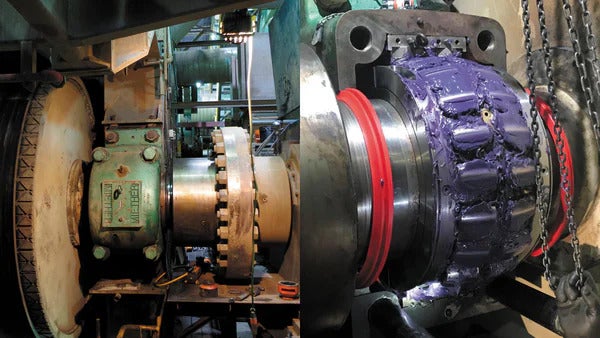

Tough conditions for a bearing exchange

Ten miles (16 km) of conveyor belt that runs through the woods on the snowy mountain side. A 6-day stockpile to handle shorter stops. And in the machine room at the end of the conveyor, an 18.5-inch (47 cm) conveyor pulley bearing that is showing signs of damage, indicated by the vibration monitoring system.

The maintenance team of the remote Colorado mine realised that installing a new standard bearing would require taking down a wall and several days of crane rental. It could also pose a high risk of injury if the pulley dropped when it was lifted out of the machine room. A bearing exchange like this would be both risky and expensive. And it would take 9 days to complete, exceeding the stockpile time limit.

A sealed split bearing solves a lot

Having worked with SKF on previous projects, the mine requested a split bearing option that could reuse the current housings. After an application review meeting, the choice fell on the SKF Cooper sealed split spherical roller bearing 231S1808-2SRS. The new bearing could easily be put in place after cutting open the old bearing and removing it from the pulley.

To protect the bearing while in operation from the fine dust surrounding the conveyor, seeming to get in everywhere, the bearing was equipped with an efficient sealing solution: The reused old housing was equipped with new machined seals rather than a standard labyrinth seal, the SKF Cooper split spherical bearing had a V-ring seal mounted directly on the bearing as a second barrier, and grease surrounding the bearing as a third barrier.

Quicker installation and run-in

The whole operation took only 4 days, instead of the 9 days it usually takes to replace the pulley bearing. Belt tension was relieved when removing the old bearing and installing the new SKF Cooper split spherical, but because the pulley remained in place, there was no need to run in the belt after installation. When a new split bearing needs to be installed, the mine is estimating the new split spherical bearing will take approximately 18 hours to install instead of a 9-day shutdown like before.

By installing SKF Cooper split spherical roller bearings instead of new solid bearings, the Colorado mine shortened the mean time to repair (MTTR) by 55% by shortening installation time and run-in time. At the same time, they improved worker safety.