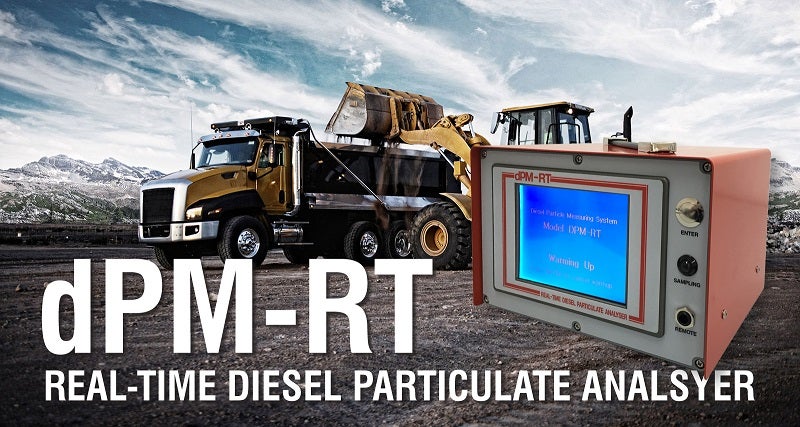

Introducing the latest locally designed and manufactured DPM technology by Pacific Data Systems, the dPM-RT Real-time Diesel Particulate Analyser.

With the World Health Organisation declaring diesel engine emissions a Class 1 carcinogen, the dPM-RT analyser is used to monitor those emissions (known as diesel particulate matter), in real-time. This important tool is used primarily to alleviate potential health concerns amongst those exposed to diesel emissions, such as vehicle maintenance workers.

Reliable, effective

The dPM-RT Real-time Diesel Particulate Analyser is the tool that ventilation officers and workshop staff need in order to reliably identify high DPM emitters, and to validate the effectiveness of emissions-related maintenance.

Key features

- Instant measurement of fine particulate levels in diesel exhaust

- Easy to use, on-screen prompts, minimal (<10min) training required

- One minute field calibration, no tools required

- Designed to handle the rugged demands of mining sites

- Meets NSW MDG 29 and QLD Govt. testing requirements

- Auto-generates and displays Stall or Free Acceleration test results

Key Benefits

Accurate measurement: the rugged, practical and easily operated DPM analysis instrument was specifically designed for measuring particulate concentrations in the exhaust of mining engines. Using advanced laser light-scattering technology, the DPM-RT can accurately and instantly measure particulate mass concentrations in the exhaust from all engine types.

Rapid results: tThe DPM-RT has been pre-programmed to measure particulate mass emissions during a Stall Test or Free Acceleration Test in as little as just one minute. Internal software guides the operator through these standardised DPM test procedures, collects and processes the test data, and automatically produces an overall result immediately once the test is completed.

For ad-hoc testing, a continuous measuring mode is also available. Data can be downloaded directly to a PC via a USB connection for storage and further analysis.

Simple operation: the instrument is highly automated, with only a single press-button required to initiate and run a test. It is designed for ease of use by maintenance personnel as an everyday workshop tool, after only minimal training, but retains the flexibility to support more complex research or investigative activities.

Routine maintenance of the DPM-RT is limited to checking and periodically replacing two disposable filters. A weekly calibration check, which takes around one minute to complete, ensures continued measurement accuracy.

Why should I conduct diesel particulate matter (DPM) measurements?

Health Concerns

- Diesel vehicles are one of the major producers of fine particulate pollution, which is linked to the incidence of severe lung and heart disease

- The World Health Organisation has declared diesel particulate matter to be a Class 1 carcinogen – the highest risk factor category

- In the confines of underground mining, where diesel engines are the dominant source of mobile power, the issue has given greater relevance and importance.

Fortunately, good maintenance can greatly reduce particulate emissions by up to 80% in some cases.

Mechanical repair cost reductions

The level of particulates in diesel exhaust is a very important indicator of engine and injector system health. Accordingly, reliable identification of high polluters and validation of repair effectiveness is essential.

Traditional methods, such as measurement of smoke opacity, have been shown to be significantly inferior to the laser light scattering technologies employed in the dPM-RT. The dPM-RT can detect and measure concentrations of particulates with a nominal diameter down to less than 100 nm (0.0001mm).

Recent advances in mine safety and occupational hygiene have resulted in a large number of diesel vehicles and plant being fitted with particle filters. These filters, when working correctly, greatly reduce particle emissions, so it is essential that their efficiency can be periodically checked The dPM-RT provides the capability to perform these checks quickly and accurately.