Caldervale Technology designs and manufactures high-quality electrofusion and butt fusion equipment for 16mm-1,200mm PE Plastic Pipe systems, also known as high-density polyethylene (HDPE).

HDPE equipment for the mining industry

Caldervale products are designed to increase productivity and facilitate installations. They are used on gas and water networks worldwide for their reliability, helping to reduce and eliminate the risk of failed welds.

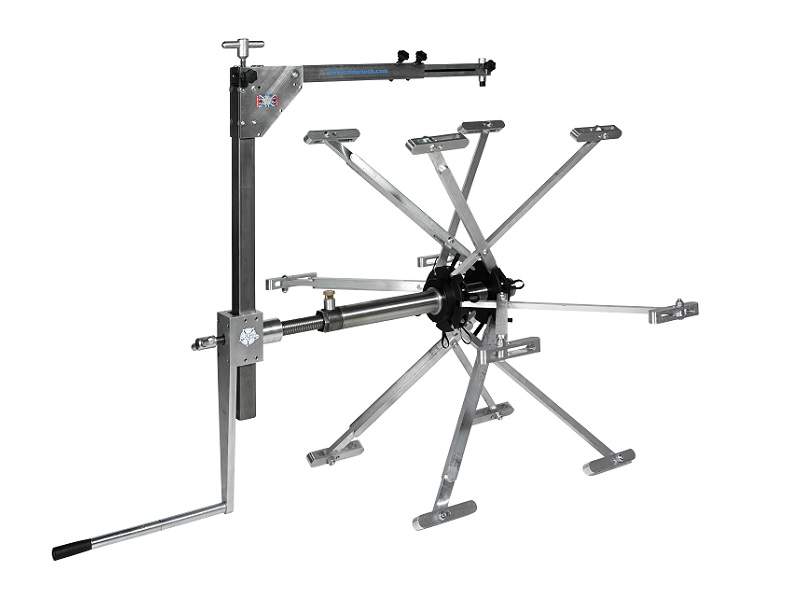

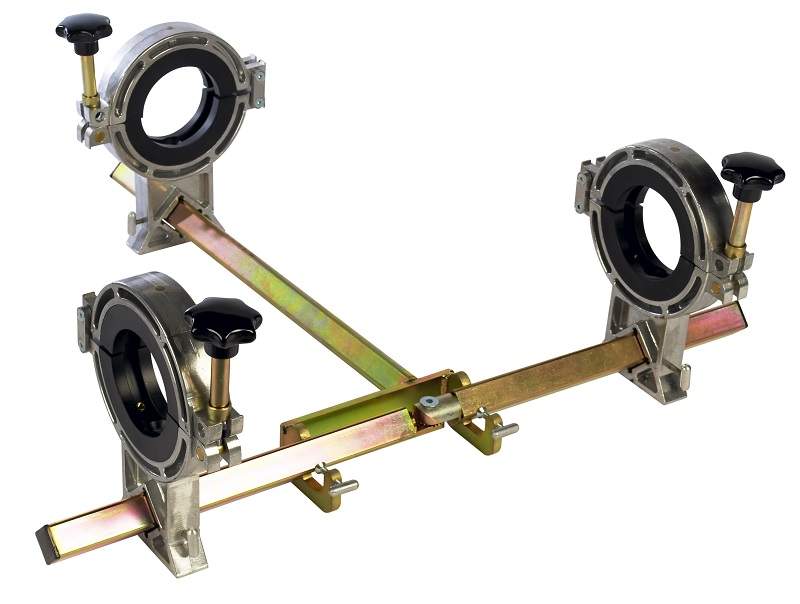

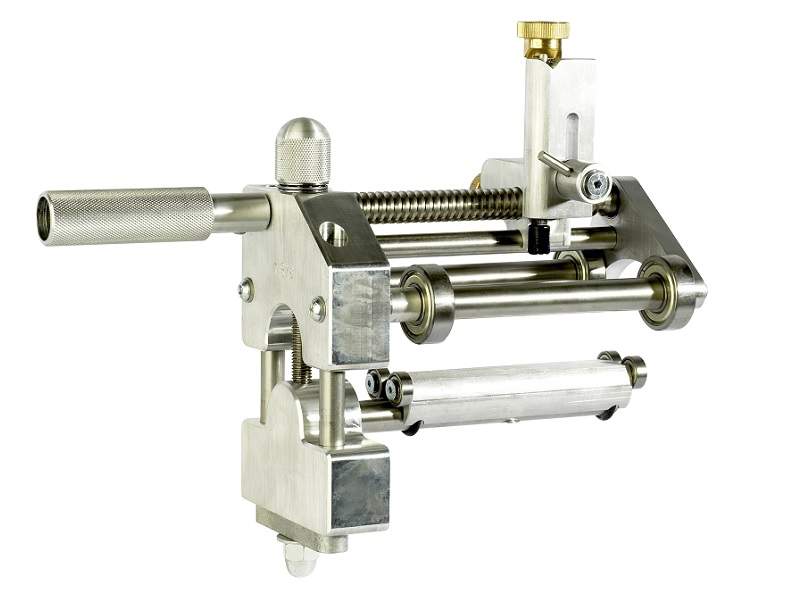

With more than 300 products, the company’s portfolio includes the Gator Automatic 63mm-400mm butt fusion machines, electrofusion welders, rotary pipe peelers, pipe clamps and positioning kits. In addition, the company offers pipe squeeze off tooling, pipe re-rounding equipment and cutting tools, including internal and external de-beading units.

Mobile data acquisition technology for weld data collection

Having the ability to monitor the welding process from your office is the most effective way to manage pipe installations.

Using mobile data acquisition technology improves long-term performance of your HDPE assets by eliminating poor installation techniques.

Caldersafe Mobile uses Bluetooth technology to collect weld data for all electrofusion joints and transmits this directly to your email inbox, providing real-time tracking.

Clients can now identify non-conforming joints by images and rectify, saving costs on projects and improving quality.

Sales, repairs and calibrations of HDPE welding equipment

Caldertech offers full support services at its facilities in Perth or through one of its service agents located across Australia, New Zealand and South East Asia.

The company’s in-house technicians and service agents are trained to high standards to carry out diagnostic tests, repairs and calibrations of your butt fusion and electrofusion welding units using specific test equipment with the latest service information supplied by the manufacturer. This reduces ownership costs and ensures products have a long service-life.

Comprehensive HDPE pipe installations

Caldertech Australia has extensive knowledge and experience in methods of installing HDPE plastic pipe systems such as pipe bursting, slip lining and mains replacement.

In addition, the company provides WASK live drilling equipment for gas and water mains up to 300mm, hot tapping machines for pipe sizes up to 900mm, and Essig Moling and pipe ramming tools.

Caldertech also offers a range of consumable products such as towing heads, foam pigs, and cutting tools for steel and HDPE.

Caldervale Technology quality standards

The company has grown a long way since it was established in 1983, but we still manufacture our butt fusion and electrofusion welding products in-house across three sites in the UK. This is part of our commitment to quality, ensuring we meet and exceed the requirements of ISO 9001 and ISO 14000, as well as industry standards in Australia and New Zealand.