A Comparison of Weighing Methods Prior to Fusion

Preparing iron samples for XRF analysis.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Malvern Panalytical creates leading material characterisation solutions for the challenges associated with maximising productivity, developing improved products and getting them to market faster.

We provide superior, customer-focused solutions and services that deliver tangible economic impact through chemical, physical and structural analysis of materials.

Comprising Malvern Instruments and PANalytical (including ASD and Claisse), Malvern Panalytical has headquarters in the Netherlands and the UK, with more than 2,000 employees worldwide. The combined entity is a leading innovator in the materials characterisation sector and incorporates their collective strengths in their end markets, ranging from construction, pharmaceuticals, mining and nanomaterials.

Our high-quality customer support is supported by a global distributor network and sales and service presence, as well as worldwide application laboratories.

Optimisation of the processing plant is mostly driven by the need to reduce energy consumption and increase margins.

Malvern Panalytical delivers innovative and unique mineral analysis solutions to increase mining operation efficiency. Our rugged and reliable systems, experience and support assist clients throughout the mining process, from exploration to final product analysis.

How to explore new mineral resources

Mobile mineralogical and elemental analysers safely obtain immediate information in the field or mine, enabling exploration and mine geologists to make real-time decisions to define the boundaries of ore bodies. Direct rock chip and core analysis on the drilling rig allows immediate decisions for improved results and higher return on investment.

How to control ore grades

Our cross-belt analysers detect ore variations directly and safely to enable precise sorting, as well as stable output to optimise the ore blending and beneficiation processes.

They can be employed for continuous, non-contact monitoring of elemental and mineralogical composition, as well as related process parameters in a large range of mining applications such as coal, copper, iron, bauxite or nickel.

How to monitor the beneficiation process

Malvern Panalytical can assist you during ore processing operations in reducing minerals extraction and energy consumption costs, mill product to the correct grade size, and monitor mineralogical and elemental compositions.

Our high-speed fusion instruments help improve sample preparation to ensure exact elemental analysis. The complete sample transportation, preparation and analysis process can be automated within a specialised laboratory.

How to check the environmental impact

Reusing, recycling and recovering mine waste is an integral factor for operating a mining business in a sustainable way, as it protects the environment against hazardous elements.

Compliance with international regulations is assured through Malvern Panalytical’s specialised solutions for elemental analysis, particle size and shape characterisation and monitoring zeta potential ensure.

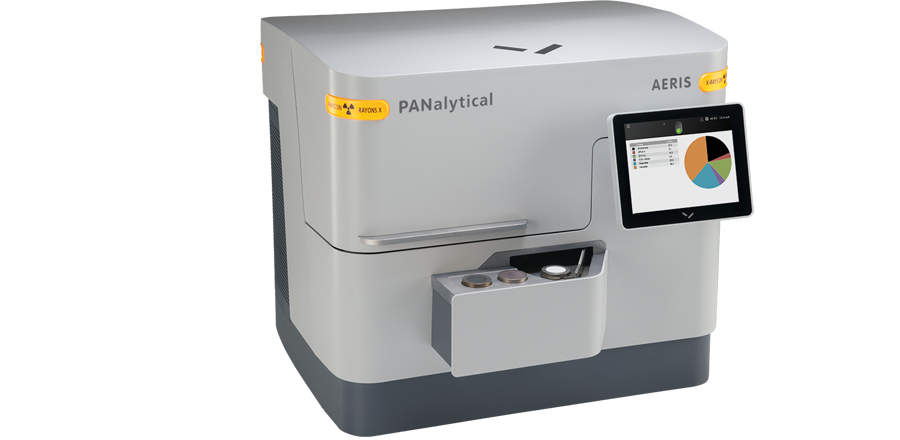

The Minerals edition of our benchtop Aeris X-ray diffractometer facilitates ore mineral analysis in the mining industry.

The XRD provides accurate mineral monitoring and input for hydrometallurgical models to achieve the most economic processing conditions.

The Aeris is your partner at every stage of the production process, from raw material to the final product.

Real-time monitoring of liquids with the Epsilon Xflow provides fast and accurate control of process efficiency during hydrometallurgical ore treatments such as:

Increased regulations and quality specifications drive the need for continuous monitoring of process flow and mine wastewater. The Epsilon Xflow provides real-time insight to manage your production processes more efficiently and reduce operational costs by reacting immediately to changes of predefined conditions.

The Minerals edition of the Zetium X-ray fluorescence spectrometer is designed for elemental analysis at all stages of the mining process.

From exploration samples to mineral concentrates, ores to tailings, the Zetium – Minerals edition offers superior flexibility, analytical performance and stability in challenging mining environments regardless of the application, and excels at major, minor and trace element quantification in geological materials.

The ASD TerraSpec range provides portable, rapid and non-destructive analysis of minerals in the lab or field.

The portable ASD TerraSpec rapidly identifies key minerals to define boundaries of ore bodies. When used as an online analyser, results are quickly presented to expedite processing decisions.

Our Insitec systems deliver online continuous particle size analysis for efficient, cost-effective monitoring and control of industrial processes.

Suitable for a wide array of process streams from dry powders to sprays, slurries and emulsions, the systems measure particle sizes ranging from 0.1μm to 2.5mm.

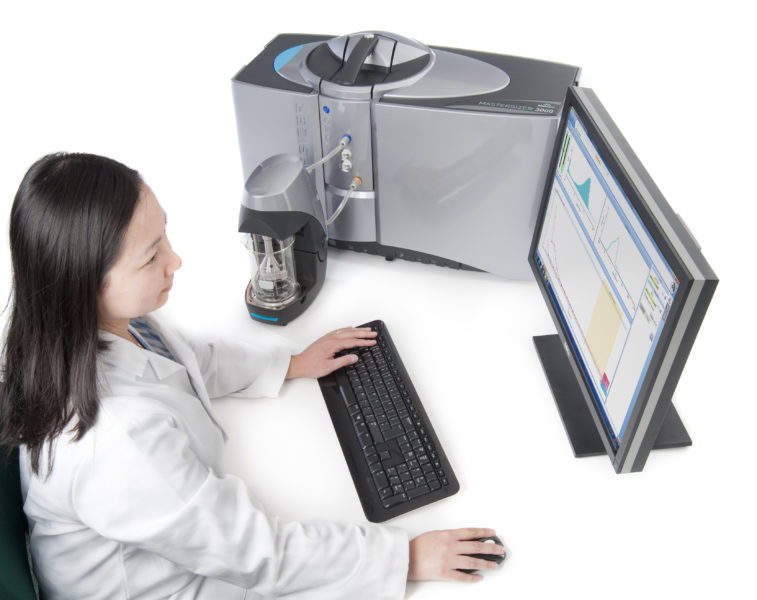

The Mastersizer 3000 laser diffraction particle size analyser is used for rapid and reliable measurement by companies and research institutes worldwide.

The analyser easily delivers fast and accurate particle size distributions for both wet and dry dispersions. Measuring over the nanometre to millimetre particle size ranges, it brings reliable operator-independent measurements.

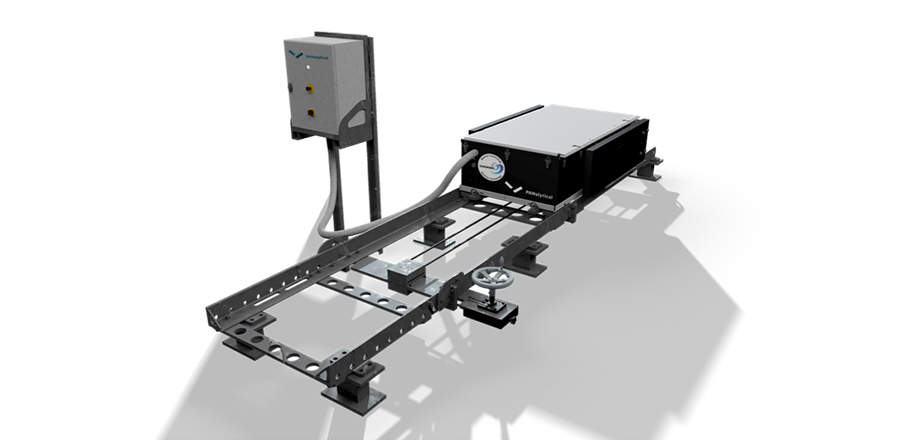

The CNA³ cross-belt analyser provides reliable real-time elemental analysis of the bulk material on the belt. No sampling is required as material is measured safely in real-time.

The compact and ruggedly designed detector is completely underneath the belt, so its performance is unaffected by variations in belt load and particle size. Stable monitoring of key components provides efficient process control to guide mining operations and reduce variability in downstream processes.

The Claisse TheOx Advanced fusion instrument is the new version of the world-renowned Claisse TheOx. Similar to the previous version, it has six fusion positions and is designed for laboratories with a high sample throughput.

Claisse TheOx Advanced is used to prepare glass disks for X-ray fluorescence (XRF) analysis, as well as borate and peroxide solutions for inductively coupled plasma (ICP) and atomic absorption (AA) examination.

For more information about Claisse, please click here to visit the company profile.

Analytical techniques that help comply with stringent norms

Silica polymorphs are widely mined. But silica only becomes a serious threat when its particles get airborne during mechanical treatment. For instance, during cutting, blasting, crashing and grinding, polishing, demolition etc. When inhaled, these particles can cause serious respiratory tract diseases and that is why occupational exposure needs to be seriously monitored and regulated.

Various techniques from atomic absorption, infrared spectroscopy to X-ray diffraction are used to analyse for airborne silica. Join our live webinar to understand the capabilities and limitations of various techniques. And why only certain techniques like XRD are accepted by ISO and EPA norms to fulfill accurate and low detection limits for airborne silica.

Preparing iron samples for XRF analysis.

A new approach to X-ray diffraction texture analysis.

To obtain maximum yields from a sulfide ore deposit, it is crucial to know the concentrations of the valuable elements in ores and concentrates at various stages of the mining process.

The age of the battery is well underway.

Malvern Panalytical will be hosting or attending a number of events in the upcoming months.

Malvern Panalytical and Concept Life Sciences combine experience and know-how in a unique partnership.

We proudly announce the extension of our product portfolio with the Kinexus rotational rheometers and Rosand capillary rheometers formerly manufactured and distributed by Malvern Panalytical.

Justin Hoover, Quality Manager at Metals and Additives LLC, discusses the company’s requirement for an instrument that was more efficient, versatile and accurate for particle size analysis.

ASTM International has announced that it will hold a board meeting and other related events in Boston, Massachusetts, US this October 13 – 16.

NMiTE (New Model in Technology and Engineering) the project to create the engineering university of the future, has announced three new appointments to its Board of Trustees.

Malvern Panalytical is proud to announce the grand opening of our application laboratory in Perth, Australia.

Always wanted to know about which analytical techniques that are most suitable for what types of materials characterization? Join our webinar by Dr Nicholas Norberg who is an application specialist in Malvern Panalytical’s supply center.

Powerful elemental analysis in a truly portable XRF spectrometer.

This data sheet demonstrates that the Epsilon 4 – a benchtop energy dispersive X-ray fluorescence (EDXRF) spectrometer – is capable of analyzing sulfur and chlorine in waste oil, without the need of helium.

The goal of this experiment was to obtain enough characterization data to differentiate between linear and branched polystyrene samples – all in a matter of minutes.

Reducing the need for time-consuming and expensive TEM analysis with Zetasizer Ultra.

The invention allows for more rapid and accurate characterization of ore materials compared to other systems of measurement.

This application note demonstrates the capability of Omnian for the analysis of a variety of industry-related samples, such as cement, metals, oils and geological samples, using default settings in only three minutes per sample.

This application note shows that the Epsilon 4 - a high-performance energy dispersive X-ray fluorescence spectrometer - is capable of analyzing major and minor elements in cement samples.

The Minerals edition of Aeris, a benchtop X-ray diffractometer, makes the versatile analysis of ores accessible for everyone in the mining industry.

Insitec systems deliver the online continuous particle size analysis needed for efficient, cost-effective monitoring and control of industrial processes.

The Mastersizer is used for rapid and reliable particle size measurement.

Online liquid analysis with the Epsilon Xflow gives the solution for fast and accurate control of your process parameters.

The Minerals edition of the Zetium spectrometer is designed for materials analysis at all stages of the mining process.

Claisse TheOx Advanced fusion instrument has six fusion positions and is designed for laboratories with a high sample throughput.

The ASD TerraSpec line of mineral analyzers provides portable, rapid and non-destructive analysis of minerals in the lab or the field.

A rugged, simple and versatile solution to your process control needs.

The intelligent diffractometer.