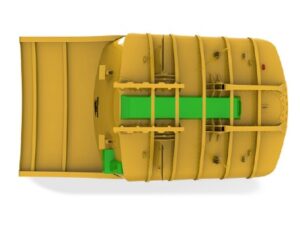

Barracuda Loader Buckets

Filling a haul truck with three and a half buckets rather than three is inefficient no matter which way you spin it, but mines around the world make this kind of mistake with buckets every day.

Not correctly payload matching your excavator, shovel and wheel loader buckets with your haul trucks means you’re giving away productivity and money with every load. Not to mention the increased cost of equipment maintenance and general wear and tear, which is often unseen.

We believe that’s not good enough.

Better payload matching is only part of the problem

Mining buckets live a hard life with some only in cycle for a matter of months before needing refurbishment. Conventional bucket builders aren’t experts at refurbishment, while conventional bucket rebuilders lack the engineering and design expertise of the specialist bucket manufacturers.

With Schlam you get both.

The Barracuda is the complete solutions

The bucket is the business end of the load and haul process. A poorly designed bucket will slow productivity and performance of the load and haul ecosystem. The biggest is not necessarily best; that’s why a fit for purpose solution engineered to suit the conditions is critical to maximise the investment in your dig machine.

Our Barracuda range of excavator, shovel and wheel loader buckets are custom made for your ground conditions, commodities, material properties and OEM earthmoving fleet. From high production lightweight buckets to armoured buckets, each attachment is tailor-made to get the best out of your fleet of load and haul equipment.

When it comes time to refurbish your Barracuda buckets, return them to us and we’ll make them like new again. We have been refurbishing buckets for over 20 years. From 20t hydraulic excavators through to 1,600t rope shovel dippers operating in some of the world’s harshest digging environments.