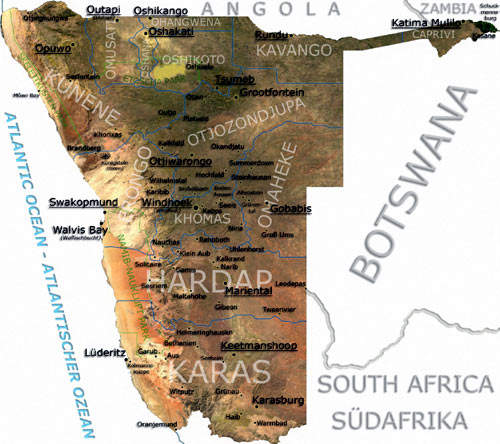

Trekkopje uranium mine is located in western Namibia in southern Africa, approximately 65km north-east of Swakopmund. The mine is owned by Areva and currently under construction. In June 2008, Areva obtained the mining license from the Namibian Government in June 2008 and has since invested more than $900m in the project.

The mine is poised to become the largest in southern Africa and the tenth largest in the world. The estimated mine life is 12 years.

Full-scale production at the mine was planned to begin in 2011 but postponed to 2012. In February 2011, Areva announced that the full-scale production was further delayed to 2013. Slump in uranium prices over the past two years and complexity of the project were cited as the reasons for the delay.

Reserves

The mine hosts approximately 340Mt of resources over an area of 128,979ha. The reserves are stated at an assumed grade of 0.014% U305.

Geology

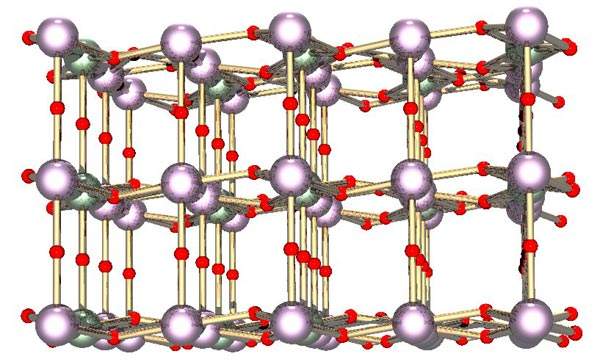

The mine combines two uranium deposits: the Trekkopje and the Klein Trekkopeje. The deposits are broad, shallow and are characterised by calcrete.

Minerals are largely found within calcium carbonate cemented conglomerates belonging to the Tertiary period. The main mineralisation extends over a 16km-long, 4km-wide area with approximately 80% of the minerals found near the surface within a depth of 15m.

Mining and processing

The mine is being developed as a very low stripping open cast operation. Mining is being carried out using conventional methods including scraping, drilling, blasting, loading, hauling and ore feeding to the treatment plant. Nearly 80% of the excavations will be conducted through drilling and blasting. Large hydraulic excavators or hydraulic shovels with 60,000t/d capacity, wheel loaders and haul trucks are being used to carry out mining activities. Ore will be crushed in a portable primary crusher located near the pit before it is transported using conveyors.

Based on a stripping ratio of 1:15, the mine will process 100,000t of crushed ore per day upon commissioning. A ROM stockpile will be installed near the primary crusher to ensure continuous ore supply over short intervals.

Six CH880 crushers are being supplied for the mine by Sweden-based Sandvik.

Desalination plant

The mine is supported by a desalination plant approximately 30km north of Swakopmund at Wlotzkasbaken. It was opened in April 2010. Processing methods, including heap leaching and ion exchange, require a desalination plant as chloride in sea and saline disrupts the process of ion exchange.

The plant is equipped with the latest technology required to perform screen filtration, ultra filtration, reserve osmosis and chemical treatment. The annual capacity of the intake pipes is nearly 45 million cubic metres.

The plant will produce 20 million cubic metres of potable water annually. Every year, mining and leaching will need approximately 17 million cubic metres of water. Sea water is treated in a reverse osmosis water treatment plant. A standard reverse osmosis desalination plant has also been built nearly 50km away on the coast to the north of Swakopmund to supply the sea water.

Production

During its lifetime, the mine will produce an estimated 8.5 million pounds of uranium oxide. Annual production will be 3,000t of uranium ore at an average grade of 120ppm. Through a mini pilot facility, the mine achieved its first production in March 2009. In this first phase of development, the mine produced a bulk sample of 80,000t of sodium diuranate. The second phase continued until the end of 2009 and produced a larger sample of three million tonne. The third phase, which will oversee full production, is due to begin in 2012. The first batch of uranium concentrate was obtained in January 2011.

Transportation

The mine is accessed through a paved highway about 70km east of Swakopmund. A graded gravel road, 23km north to the mine site, follows the highway. The mine is also close to power and rail transport.