Tapuli iron ore mine is located 5km from the Sahavaara magnetite deposit in the Norrbotten District of Northern Sweden.

Owned by Northland Resources, the project is advancing towards production, following an environmental permit grant from the Finnish-Swedish Border River Commission in August 2010. The permit allows mining of 100mt of magnetite ore a year.

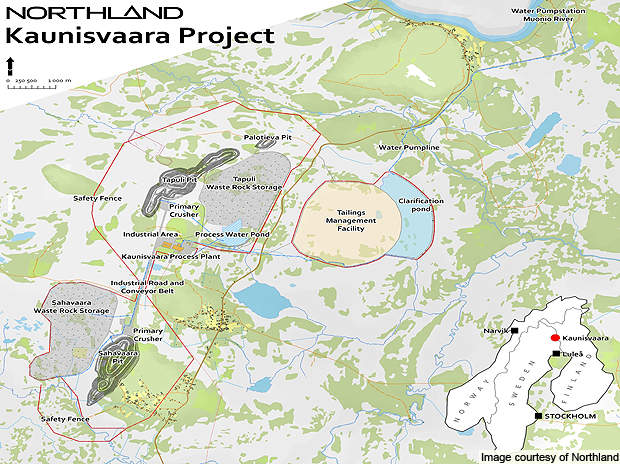

The mine forms part of the Kaunisvaara project that also includes the Sahavaara magnetite iron ore deposits and the Kaunisvaara mill. The Tapuli mine is expected to begin production by the end of 2012.

Tapuli reserves

The mine has 52.4mt of measured resources estimated with an average grade of 27.02% Fe. The total indicated resources at the mine have been estimated at 54.6mt grading at 25.04% Fe. The inferred resources total 24.7mt with an average grade of 24.58% Fe.

Geology

The Tapuli deposit is hosted at a major flexure along the westernmost shear region of the Pajala Shear zone, a crustal scale major regional feature trending across the border into Finland.

The Pajala shear zone measures 50km to 100km in width and consists of a system of thrust and reverse faults. It includes Paleoproterozoic aged metasedimentary rocks that overlie a greenstone unit and comprise quartzites, dolomites, phyllites and schists.

The Pajala shear zone forms part of the Baltic-Bothnian mega shear and hosts approximately 30 iron oxide deposits. Intrusives in the immediate region of the deposits are largely gabbro and diabase.

The Tapuli deposit extends more than 2000m along strike and is hosted as a partially continuous mineralised trend with moderate irregular displacements caused by cross cutting, semi-vertical faults. Up to 11m thick glacial till, gravel and sandcover overlie the deposit area. There are almost non-existent bedrock exposures.

The largest section of the deposit, hosted at the centre, is located at the focus of the flexure of the Pajala shear zone. This section starts near the surface and extends up to a depth of 300m with bands of up to 200m thick contiguous magnetite mineralisation.

The mineralisation is open at the down-dip limits of the deposit with an undefined vertical extent. Mineralised bodies dip at between 450 and 600 and trend primarily west-northwest and north-west.

The mineralised bodies occur as breccia-style lenses and bands of higher grade magnetite / serpentine skarn hosted within lower grade magnetite-hosting clinopyroxene / amphibole skarns and skarn breccias.

There are seven mineralised lenses namely Tapuli South, Tapuli Central Upper and Lower, Tapuli North Upper and Lower, and Palotieva Upper and Lower.

The mineralised lenses follow a 2km-long stratigraphic corridor and are found amid hanging-wall phyllite units and footwall dolomites, schists and graphitic schists.

The mineralised bodies are enveloped by Metasomatic skarns. Throughout the enveloping mineralised breccia zones, the magnetites are interleaved and are up to 100m in thickness.

Mineralisation

Mineralisation at Tapuli is predominantly magnetite with chalcopyrite, pyrite and pyrrhotite found in trace amounts.

Lenses at the north end of the deposit and the lower-most layers of the deposit near the footwall contain a higher percentage of the minerals. The mineralisation has relatively low sulphide content.

Mining and processing

The Tapuli resources will be mined using open pit methods including drilling, blasting, and a fleet of tracked wheel loading equipment, shovel and conventional haul trucks. Drilling and blasting will be carried out on benches with a 12m height. The blasted material will be extracted to the pit rim in a single pass.

At full production, approximately 35mt of ore and waste will be moved annually. Ore will be transported via trucks to a crushing station that will be located close to the pit exit. The material will be fed from the crushing station to the processing facility located adjacent to the mine via a conveyor system.

The processing plant will operate at a nameplate capacity of 12mtpa. It will include two streams, stream 1 on the northern side and stream 2 on the southern side, each designed to process 6mtpa of ore.

Ore from the Tapuli mine will be treated in stream 1. Processing of the ore will include primary crushing, blending stockpiles, primary milling, primary magnetic separation, secondary grinding, secondary magnetic separation based on low intensity magnetic separation, magnetite concentrate filtration, final concentrate storage and truck loadout.

Drilling

Drilling at the Tapuli mine in 2004 totalled 26 holes extending 6,280m by 2004 when Northland Resources acquired the deposit.

As the area was already explored, Northland Resources was able to advance directly to in-fill and deeper hole drilling. In 2007, Northland Resources drilled 37 holes extending 5,697m. The drilled holes were incorporated into the existing database.