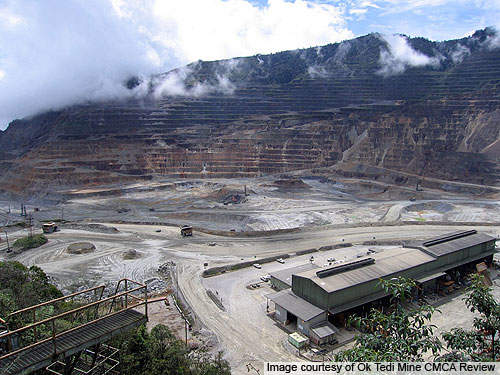

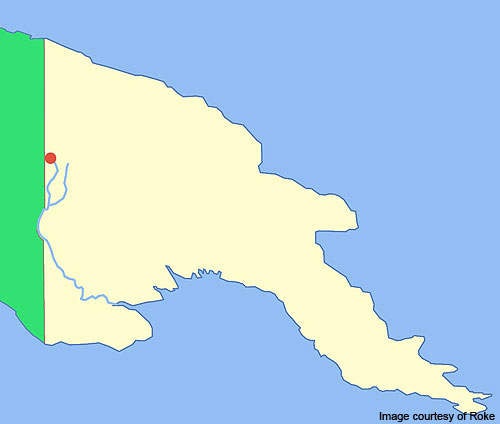

The OK Tedi Mine is an open cut copper operation located in Papua New Guinea, close to the headwaters of the OK Tedi River. Discovered in 1968, the mine is operated by Ok Tedi Mining Limited (OTML), a wholly owned company of the mine owner Papua New Guinea Sustainable Development Program Limited (PNGSDPL).

The mine began producing gold in 1984. Copper production followed in 1987. The mine is a major supplier of copper concentrate to the smelting markets in Germany, India, Philippines, Korea and Japan.

A phased closure of the mine is planned for 2013. A feasibility study to evaluate the possibility of extending mine life by seven years, from 2014 to 2022, was undertaken in 2009. The expansion will combine two underground mines and one open pit mine.

The extension is expected to result in 700,000t of copper production and 2.3moz of gold production, generating K3bn in state revenues over the seven-year period. The mine currently produces 160,000t of copper and 540,000oz of gold.

Production resumed in June 2011 after being suspended in May 2011 following concerns over a ruptured pipeline. The halt in production had resulted in losses equivalent to $5.5m a day.

Gold and copper reserves

As of December 2009, the mine contained 113 million tons (mt) of proven and probable reserves graded at 0.8% Cu and 1.1g/t Au.

Geology and mineralisation

The deposit lies within the northern edge of the proterozoic to paleozoic aged basement rocks of the Australian continent. The rocks are hosted beneath a fold-thrust belt of mesozoic and tertiary aged platform rocks. The Ok Tedi deposit is hosted within miocene to pleistocene aged igneous intrusive in the belt.

The local geology surrounding the deposit is characterised by continental margin marine sedimentary siltstones, mudstones and limestone concentrated during the cretaceous to mid-miocene period.

The Ok Tedi skarns were produced as a result of the Sydney monzodiorite emplacement that led to the replacement of limestone / carbonate facies due to a chemical alteration with the magmatic fluids.

The relatively unmetamorphised Sydney monzonite is gold and copper enriched only at the contact with the fubilan monzonite porphyry. The fubilan monzonite porphyry that cuts across the Sydney monzodiorite hosts the major copper gold mineralisation at the property. The structure also intrudes the related stocks, breccias, skarn bodies and shallow dipping sediments.

Intrusives, skarns and fractured siltstones near to the intrusive stocks host the protore copper, gold and silver minerals at the deposit which primarily includes chalcopyrite with pyrite-marcasite and trace amounts of bornite and molybdenite. Sparsely distributed sphalerite and galena occur within the deposit margins and skarns. In both skarns and intrusive rocks, gold is found with the copper mineralisation.

The main ore body is overlain by an oxide gold cap developed due to the extensive leaching and oxidation of the sulphide minerals. A supergene enriched copper zone of chalcocite and digenite directly underlies the oxide cap.

Mining processes in Papua New Guinea

Mining activity at OK Tedi is performed on a continuous basis throughout the year, producing approximately 78,000t of ore and 80,000t of overburden. Open pit methods including drilling and blasting are employed.

The blasted rock, excavated along 15m high pit benches, are loaded into haul trucks using three large 3 RH 200 O&K hydraulic shovels. The fleet of haul trucks includes 23,170t Caterpillar 789 haul trucks and three 100t Caterpillar 777D haul trucks.

Additional mining equipment includes three Hitachi hydraulic excavators, three Atlas Copco Pit Viper drill rigs, one Tamrock drill rig, ten Caterpillar D11 dozers, two Caterpillar 992 loaders, three Caterpillar 16H graders and two Caterpillar 834B rubber tyre dozers.

Processing ore

The ore is crushed onsite to less than 200mm size in large gyratory crushers. The crushed ore is conveyed to a primary stockpile from where it is fed to the 78,000t processing facility’s grinding circuit. The grinding circuit, equipped with semi-autogenous grinding (SAG) mills and ball mills, reduces the ore to sand.

In the flotation cells, the ore is added with collector reagents and frother reagents. These reagents help to form air bubbles besides allowing the copper and gold minerals to attach to air bubbles.

As the air bubbles float to surface, the ascended minerals can be collected. The froth is collected as a mineral concentrate containing 28% to 31% copper and 20g/t Au. It undergoes multiple phases of flotation to increase froth concentration.

The concentrate is thickened and sent as slurry to the river port of Kiunga through a 157km pipeline. It is filtered, dried and stockpiled ahead of transportation.