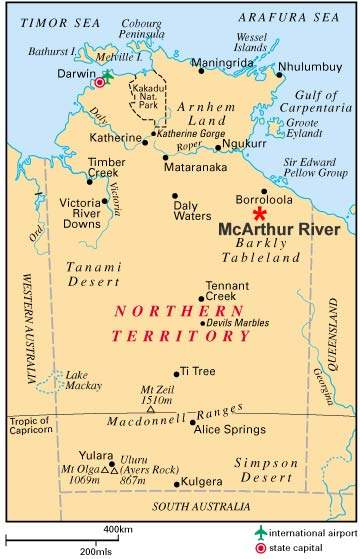

In 1955, MIM discovered the Here’s Your Chance (HYC) zinc-lead-silver deposit on the McArthur River Station, 900km southeast of Darwin and 100km inland from the Gulf of Carpentaria in Australia’s Northern Territory. For 30 years, studies failed to develop a viable production concept, given the costs of building the infrastructure needed. However, in 1989 the company started a prefeasibility study with more cost-effective parameters: selective underground mining and ultra-fine grinding to produce a single zinc-lead concentrate for shipment to its Avonmouth Imperial Smelting Process plant, with government-assisted infrastructure development.

The results encouraged MIM and the specially formed consortium, ANT Minerals Pty Ltd, to establish the McArthur River mine (MRM) as a 70:30 joint venture with MIM as the manager. The go-ahead was announced in 1992 and the operations were officially opened September 1995, helping to compensate for declining reserves in the Mount Isa area mines (see separate profiles).

ANT Minerals was a consortium of Japanese firms in which Toyoha Mines (a Nikko Kyodo subsidiary) had a 50% interest and Marubeni, Mitsubishi Materials and Mitsui 16.6% each.

MIM acquired a further 5% holding during FY2002, while its 75% holding was transferred to Xstrata in 2003 following the companies’ merger. MRM now operates within the Xstrata Zinc business unit, Xstata having bought the ANT stake in the project.

In late 2006, Xstrata received government approval for the conversion of McArthur River from underground mining to an open-pit operation. The Northern Territory Government funded about $110m for the open pit development programme.

Plans to convert the mine from an underground to an open pit operation were delayed in mid-2008 when the traditional aboriginal land owners opposed the expansion in the courts. Australia’s Northern Territory government responded by hurrying through a new piece of legislation which cleared the way. In its 2007 annual report Xstrata said that the open pit development was going well with the completion of the Barney Creek diversion and the McArthur River Rechannelling that was completed in the second quarter of 2008 following the wet season. A 5.5km section of the McArthur river was re-channeled.

However, in December 2008 all mining and civil works at MRM were stopped following the judgement of the Federal Court. The decision was based upon procedural errors by the Commonwealth Government.

In February 2009, the suspended programme was approved by the Federal Environment Minister on the basis of a few conditions.

The conditions included best practice of environmental management and community consultation, and regular studies on freshwater sawfish and migratory birds in the vicinity of the mine.

The Northern Territory Government appointed an independent environmental monitor to carry out the mine’s environmental monitoring and management programmes. In the second annual assessment of the programme, the monitor indicated that the mine has requisite qualities or resources for the development of an $110m open pit project.

The independent monitor also indicated that the mine had conformed to the commitments and conditions required for the open pit project.

Geology and reserves

The shallow-dipping stratiform deposit occurs in the HYC Pyritic Shale Member. This package of inter-bedded pyritic siltstone, sedimentary breccia and tuff lies within a belt of sedimentary rocks of Middle Proterozoic age. Seven stacked sulphide orebodies are separated by dolomitic siltstones and sedimentary breccias. Thin tuff bands are common throughout the 55m-thick sequence (average).

As of mid-2009, Xstrata stated that McArthur River had proved reserves of 7 1.6Mt graded at 8.5% zinc, 4.4% lead and 67g/t silver, and 80.0Mt of probable reserves graded at 6.9% zinc, 3.9% lead, and 68g/t silver. Measured, indicated and inferred resources totalled 292.8Mt, 192.1Mt and 163M,t respectively.

The planned change from underground to open-pit mining has led to a recalculation of reserves at the property, with Xstrata quoting open-pit mineable mineral resources as 100Mt grading 12% zinc, 5% lead and 50g/t silver as of mid-2005, plus underground resources of a further 8.3Mt of ore at 14% zinc, 5.6% lead and 58g/t silver.

Underground mining

Access to the underground mine is provided by two declines, one for personnel and equipment and the other with an ore conveyor from the underground jaw crusher. The zinc-rich high-grade No.2 orebody has been worked first by room-and-pillar mining using a standard drill, blast, muck and ground-support cycle. Low-profile loaders dump into 50t-capacity trucks that make the less-than 800m haul to the crusher.

The lower-grade Nos.3 and 4 orebodies allow bulk mining by open stoping and bench mining, with loading on the No.2 level. The change-over to open-pit mining will involve re-equipping the operation.

Ore processing

Up to four reciprocating plate feeders reclaim crushed ore from the stockpile for SAG milling ahead of flotation. The rougher concentrate is reground to below 10 microns using Xstrata Technology’s proprietary IsaMills technology. Cleaner flotation then upgrades the mixed concentrate from 42% to 46% zinc. Test work in 2004 led to flowsheet modifications to increase zinc grade and reduce silica in the concentrate. High-rate thickeners feed Larox pressure filters, which discharge about 360,000t/y of concentrate via conveyors to storage.

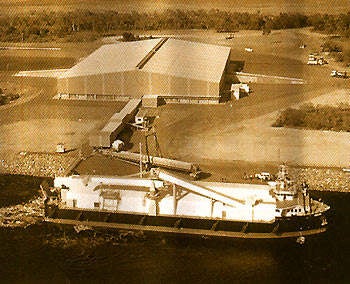

It is not economic to ship the concentrate to Mount Isa so it is exported. Material is trucked 120km to a purpose-built ship-loading terminal at Bing Bong. Here a barge transfers material from the terminal to bulk ships moored 30km out to sea.

One option studied for the conversion to open-pit mining involved the production of zinc at MRM itself, using the group’s direct-leaching Albion Process and, possibly, a 456,000t/y electrowinning and casting facility for SHG zinc and zinc-aluminium alloy. Xstrata is retaining the option to install an Albion refinery at a later date.

In January 2007, approval was granted to increase the capacity of the concentrator at McArthur River Mine from annual throughput of 1.8 million tons of ore to 2.5 million tons of ore, for a capital cost of $37m.

The expansion of the concentrator was completed in 2008. The expanded capacity was achieved in 2009. The feasibility study to construct an Albion process atmospheric pressure leaching plant is under-way. Potential locations for an Albion plant continue to be examined, including the potential for a greenfield smelter on the east coast of Australia or a brownfield expansion at an existing Xstrata Zinc smelter. Construction of the plant will be completed by the end of 2010.

Production

Annual production for 2007 was 1.9Mt of ore, 138,000t zinc-in-concentrate. McArthur River Mine continued its open pit development, mining from Stages B, C and transitional ore from Stage D during the year. Stripping began from Stage E in late 2007 to provide a further mining area to support increased production in 2008.

A fall in average head grade from 11% in 2006 to 10% in 2007 was due to the mining of transitional ore from the open pit Stages C and D. Mining production increased by 4% year-on-year. Zinc metal production increased by 2%, reflecting a 6% increase in throughput tonnage, partially offset by the treatment of transitional ore stockpiles.

The total ore milled in 2009 stood at 2.1Mt, an increase of 3% from 2008. Approximately, 166,400t of zinc metal was produced in 2009, an increase of 17% over 2008.