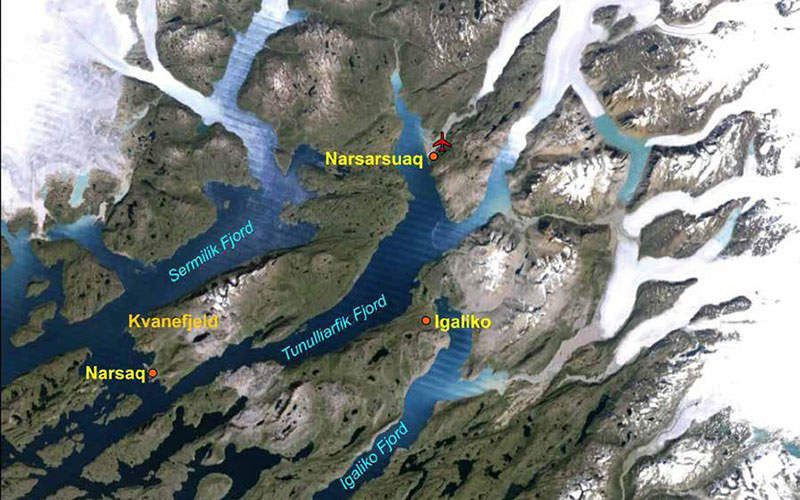

Greenland Minerals and Energy’s (GMEL) flagship Kvanefjeld Rare Earth – Uranium Project is located within the municipality of Kujalleq, approximately 8km from the town of Narsaq, and 35km from Narsarsuaq, in southern Greenland.

The project’s pre-feasibility study was completed in May 2012, whereas the feasibility study was completed in May 2015.

Construction works are expected to start following the grant of certain regulatory approvals, which include the application for mining licence EL 2010/02, which is anticipated in early-2016.

The overall investment in the project is estimated to reach $1.36bn, which could further reduce as a result of the optimisation studies being conducted. The project is expected to generate 1,171 construction jobs and 787 jobs during operations.

The rare earth mine is estimated to have an initial production life of 37 years, based on an ore processing rate of three million tonnes per annum (Mtpa).

The project is expected to produce a mixed critical rare earth concentrate, including neodymium, praseodymium, europium, dysprosium, terbium, and yttrium, as well as by-products including triuranium octoxide (U₃O₈), lanthanum and cerium products, zinc concentrate and fluorspar.

Geology and mineralisation

The Kvanefjeld mine is located within the northern Illimaussaq Intrusive Complex, a layered peralkaline intrusive body (Mesoproterozoic in age) measuring approximately 8km x 15km. It hosts three deposits namely Kvanefjeld, Sørensen and Zone 3.

The complex hosts an unusual rock-type called lujavrite. The rare earth elements (REEs) and uranium are primarily hosted in an unusual phosphor-silicate mineral called steenstrupine within the upper sections of the lujavrite.

Kvanefjeld project reserves

The project is expected to be one of the world’s biggest undeveloped resources of rare earth elements, with JORC 2012-compliant resources of one billion tonnes. The current project involves the development of the Kvanefjeld deposit, which is estimated to hold 143 million tonnes (Mt) of measured resources.

As of May 2015, the Kvanefjeld mine is estimated to contain JORC 2012-compliant proven and probable ore reserves of 108Mt.

Mining and processing at the multi-element project

Open-cut mining methods integrating a conventional drill-blast-truck-shovel operation have been proposed for the project. The mining fleet will include up to six 100t trucks and a 200t excavator.

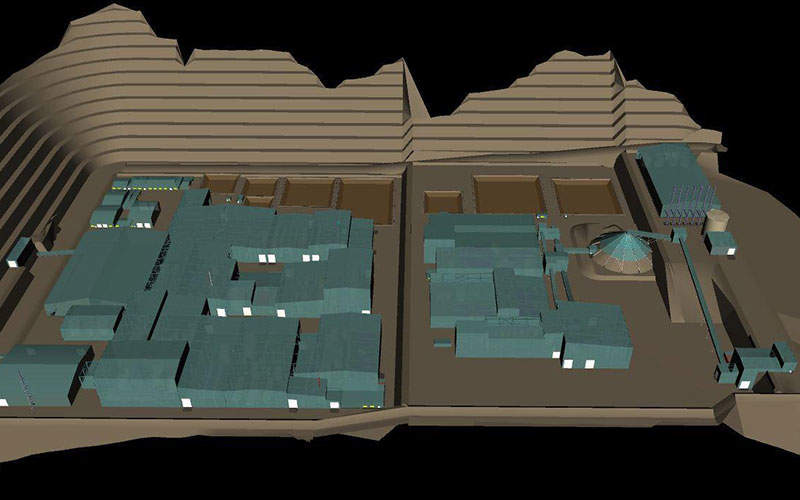

The processing facility will comprise a concentrator plant and a separate refinery plant, both located at the same site at the upper end of the Narsaq Valley.

The former will integrate a beneficiation circuit using froth flotation to produce a concentrate rich in rare earth elements (REEs) and uranium while the refinery plant will use a four-phase process integrating conventional atmospheric acid leach, solvent extraction and precipitation to separate rare earths and uranium oxide.

The beneficiation circuit for the project was piloted at three different facilities and completed in June 2015, whereas the refinery piloting was successfully completed in October 2015 at Outotec’s Pori Research Laboratories in Finland.

The pilot operations were conducted as part of the EURARE programme, which is funded by the European Commission for the development of Europe’s rare earth ore deposits.

GMEL has signed two memorandums of understanding (MoUs) with China Nonferrous Metal Industry’s Foreign Engineering and Construction (NFC) to perform the concentrates separation at the latter’s facilities, being constructed in Xinfeng, China; the country touted to be the world’s biggest rare earth metal producer.

Infrastructure at GMEL’s flagship project

The project’s infrastructure will include a raw water dam, a water treatment plant, a chlor-alkali plant, a waste rock dump, a flotation tailings storage facility (FTSF), a chemical residue storage facility (CRSF), and administrative and technical staff offices.

The electricity and heating requirements for the project will be met through a new 59MW heavy fuel oil (HFO) combined heat and power plant located adjacent to the processing plant, whereas the raw water requirements will be met through the Narsaq River and from the tailings facilities.

A new sea port with a 200m quay front integrating conveyors and mobile stackers will be constructed at Ilua Bay. A new 13km-long access road will be constructed to connect the accommodation camp with the mine and the harbour.

In the early construction stage of the project, the workers will be accommodated at Narsaq and Narsarsuaq, while an accommodation village will be constructed during this stage near the port facility.

Key players involved with southern Greenland’s rare earth – uranium project

The feasibility study was compiled principally by SRK Consulting, who conducted the geology and resource evaluation and provided the mine design, while the metallurgical studies were conducted by SGS laboratories, ALS Ammtec and ANSTO.

Tetra Tech Proteus conducted the process plant design studies while the infrastructural studies were conducted by Ramboll, Istak and Verkis, and the environmental studies were performed by AMEC Foster Wheeler, Orbicon, and Danish Hydraulic Institute.

The capital cost analysis was done by Non Ferrous China, Macmohan and Tetra Tech, whereas the market analysis was done by Adamas Intelligence. The optimal shipping solution study for the project was conducted by Blue Water Shipping.