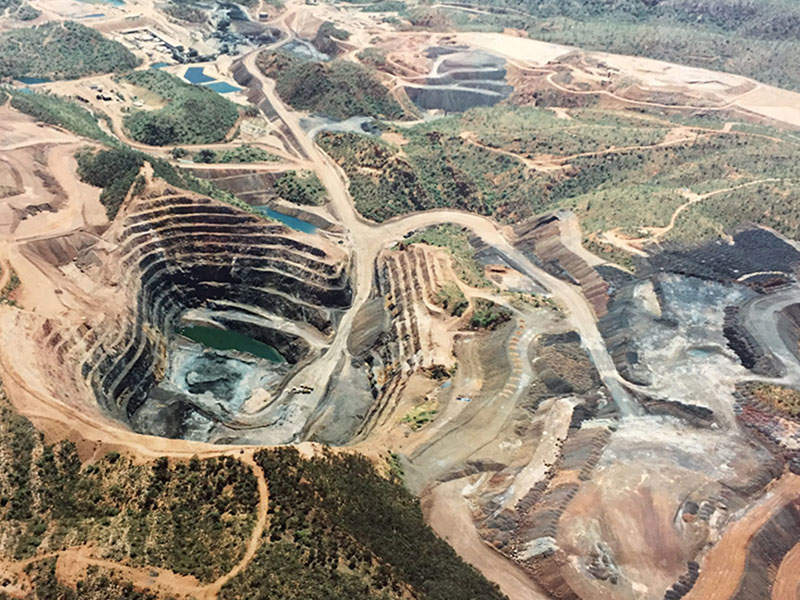

The Capricorn copper mine (formerly Mt Gordon and Gunpowder mines) is one of the largest copper mining projects being undertaken in Australia. The high-grade resource is expected to contain more than 900,000t of copper metal and is anticipated to produce 30 kilotonnes per annum (ktpa) of copper concentrate over its initial mine life of ten years.

The Capricorn Copper joint venture between Lighthouse Minerals (LHM) and EMR Capital (EMR) acquired the mine in October 2015 from Aditya Birla, a company based in India. The Queensland government granted ‘Prescribed Project Status’ for the copper mine in April 2017.

The copper mine underwent a A$110m (approximately $81m) refurbishment and restart programme. The mine produced first copper concentrate in November 2017 and has produced 10,000 dry metric tonnes (dmt) of concentrate by 28 January 2018. The first concentrate shipment was made in February 2018.

The project created more than 350 full-time operational and construction jobs during 2017. It is expected to generate approximately 220 full-time jobs.

Details of the Capricorn refurbishment and restart programme

Capricorn Copper has initiated restart execution studies (RES) to identify the prospects of restarting operations at the Capricorn copper mine. A restart and refurbishment project (RRP) has been established to estimate the capital costs and undertake readiness programmes required to restart mine operations.

The study concluded that the desired operational efficiencies could be achieved through the maintenance of existing facilities, replacement of outdated technology, expansion of existing production system, and construction of new equipment / facilities.

Commissioning of new process equipment reduces the project’s risk profile. The concentrator refurbishment was completed in 2017 while the mine was recommissioned in the fourth quarter of 2017.

Geology and mineralisation of Capricorn copper mine

Located approximately 125km north-west of Mt Isa in north-west Queensland, the copper mine is hosted within the Western Fold Belt of the Mount Isa Inlier. The Inlier comprises early to middle Proterozoic rocks and hosts three tectonic units, namely the Western fold belt, the Kalkadoon – Leichhardt belt, and the Eastern fold belt.

The Western fold belt is further categorised into the Lawn Hill Platform, Leichhardt River Fault Trough, Ewen Block, and the Myally Shelf zones, while the Eastern belt is categorised into the Mary Kathleen, Quamby-Malbon, and Cloncurry-Selwyn zones.

The Capricorn copper project occurs within the western part of the Leichhardt River Fault Trough and is connected with a regional scale transpressional dextral strike-slip system called the Mount Gordon Fault Zone (MGFZ).

The mine comprises five deposits, namely Mammoth, Mammoth North, Esperanza-Pluto, Esperanza South, and Greenstone.

Most of the copper mineralisation at Capricorn is hosted as a set of interconnected east to north-east trending faults and fault splays interconnected with the north-trending MGFZ. Mineralisation occurs in stockwork veins, breccias and as adjacent replacement of host rocks located within and close to the faults.

Capricorn copper mine reserves

The proven and probable ore reserves of the Capricorn copper mine are estimated at 8.47 million tonnes (Mt) containing 167,600t of copper metal grading 1.98% Cu.

The total measured, indicated and inferred resources of the Capricorn mine are estimated at 127.89Mt containing 1,686,312t of copper metal grading at 1.32% Cu.

Mining and processing of ore from Capricorn copper mine

The Capricorn copper mine has seven closely located primary ore bodies, and mining being conducted from multiple ore bodies through two declines.

Ore mining at the Esperanza South deposit commenced in April 2017 and the refurbished water treatment plant was commissioned in October 2017.

The longitudinal sub-level caving (LSLC) method of mining is applied at the Esperanza South deposit while long-hole open stoping (LHOS) with paste fill is being applied at all other deposits.

The mine features an existing portal at Mammoth deposit, which provides an access to the Mammoth Deeps, Greenstone, Mammoth North, East and Pluto deposits. The Esperanza South underground mine lies to the south-west of the existing Mammoth workings and comprises an independent decline and supporting mine infrastructure.

The current processing unit comprises a conventional copper sulphide flotation concentrator. The existing equipment is refurbished and a regrind mill has been added to allow the plant to process up to 1.7Mtpa of ore from multiple ore sources.

The concentrator comprises a single toggle jaw crusher, feeding a coarse ore stockpile, and a comminution circuit consisting of a closed semi-autogenous grinding (SAG) and ball mills paired with a hydro-cyclone cluster.

The rougher flotation circuit generates three separate rougher concentrates (high, middle, low grades), which passes through three cleaner flotation stages. The concentrate is then taken through the conventional thickeners for producing final copper concentrate.

The concentrate produced at Capricorn mine is transported to the Port of Townsville in sealed half-height containers for export.

Infrastructure facilities at Capricorn copper project

The Capricorn copper mine is using the existing operating and support infrastructure, including a processing plant, existing mine declines and development, site infrastructure and offices, as well as established power and water supply facilities.

Byrnecut completed the installation of the Esperanza South overhead powerline, site earthworks, and other establishments during the first quarter of 2017.

Financing

In July 2017, Capricorn Copper signed a A$45m ($35m) senior facility agreement with BNP Paribas for the Capricorn copper mine development.

Capricorn Copper appointed Treadstone Resource Partners as financial adviser and Allen & Overy as legal adviser for the transaction. BNP Paribas engaged Allens Linklaters as legal adviser.

Key players involved

Byrnecut was awarded the mining contract for the underground Capricorn copper project in December 2016. The contractual scope also included underground mine rehabilitation, pre-production development, and production.

AEC Group prepared the economic impact assessment (EIA) report for the copper mine.

In 2017, Finland-based technology company Outotec was awarded an engineering, procurement and construction contract for a modular paste backfill plant, which comprised the Outotec® Modular Paste Backfill Plant (MPB 80).

Engineering company Ausenco was engaged in managing the concentrator and surface infrastructure operations and maintenance (O&M) from 2018 to 2024. Ausenco improves plant output by 30%, plant runtime (or reliability) and copper recovery by 9%, copper concentration (product) rate by 7%, unit costs ($/t) by 10%.