ABB, the leading power and automation technology group, has won an order to provide two dual pinion high-speed ring-geared mill drive systems for the Katanga expansion, in the Province of Katanga, Democratic Republic of Congo (DRC).

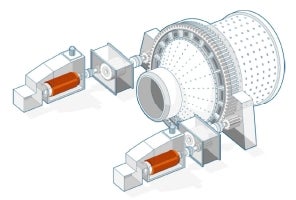

ABB’s ring-geared mill drive (RMD) solutions are designed for reliable, long-life and low maintenance operation. Features include real-time frozen charge protection, the frozen charge remover function, controlled roll back, positioning without an additional drive and variable-speed. These features and drive characteristics enable smooth mill operation, reduce maintenance needs, increase energy efficiency and availability of the complete production line, thus optimizing the grinding process and making it ideal for ores with varying grinding properties. In addition, end-users benefit from operating cost savings as it uses less electricity than a conventional fixed-speed mill drive.

The scope of supply includes two 4.75MW wound rotor induction motors, ACS6000 frequency converters with mill application controller and remote diagnostic facilities, transformers, medium voltage cubicles and engineering for one 23ft diameter run-of-mine ball mill, designed and supplied by FLSmidth.

The innovative energy-efficient RMD technology and capability for a fast-track delivery combined with ABB’s extensive industry knowledge and grinding references were significant factors for winning this order.

Katanga Mining Limited, majority owned by Swiss commodity trader Glencore PLC, operates the large-scale DRC copper-cobalt project, which includes high-grade mineral reserves and metallurgical operations.

The contract was awarded by FLSmidth in May 2013 and first deliveries are scheduled for Q1, 2014.