Mining remains one of the world’s most hazardous industries, with heavy machinery operating continuously in confined, abrasive, and unpredictable environments. Key pieces of mining equipment, including excavators, drilling rigs, and wheel loaders, depend on hydraulics to deliver controlled, precise movement.

This precision supports safety by limiting overrun and overload, stabilising heavy loads, and reducing the need for close human interaction with dangerous machinery. In high-risk environments, the ability to operate equipment remotely and shut down systems instantly when hazards arise further protects operators and maintenance teams. Unlike electrical or mechanical systems that can generate sparks, hydraulic systems are also spark-free, making them suitable for confined spaces where gases or combustible dusts may be present.

However, hydraulics are highly vulnerable to harsh environmental conditions. Dirt, rock fragments, water and chemicals can breach cylinder seals, contaminating hydraulic oil and causing rod scoring, seal degradation and eventual failure. As Leigh Carlson, CEO of Fluid Control Services, explains: “Without protection, rods corrode, and seals break down. Companies then face expensive re-chroming or full cylinder replacement, along with unplanned downtime.”

Beyond mechanical wear, damage to hydraulic cylinders can cause knock-on failures throughout the system. Contaminated hydraulic fluid can compromise pumps, valves, and control components, escalating a minor issue into a system-wide failure. As these cascading breakdowns develop, repair timelines lengthen and safety risks increase, making protection essential.

Protecting hydraulic systems to prevent downtime and injuries

A failed hydraulic cylinder poses a safety risk; sudden pressure loss or uncontrolled movement can halt production instantly and, in worst-case scenarios, endanger operators. Preventive protection plays a crucial role in extending equipment life while safeguarding the people working around it.

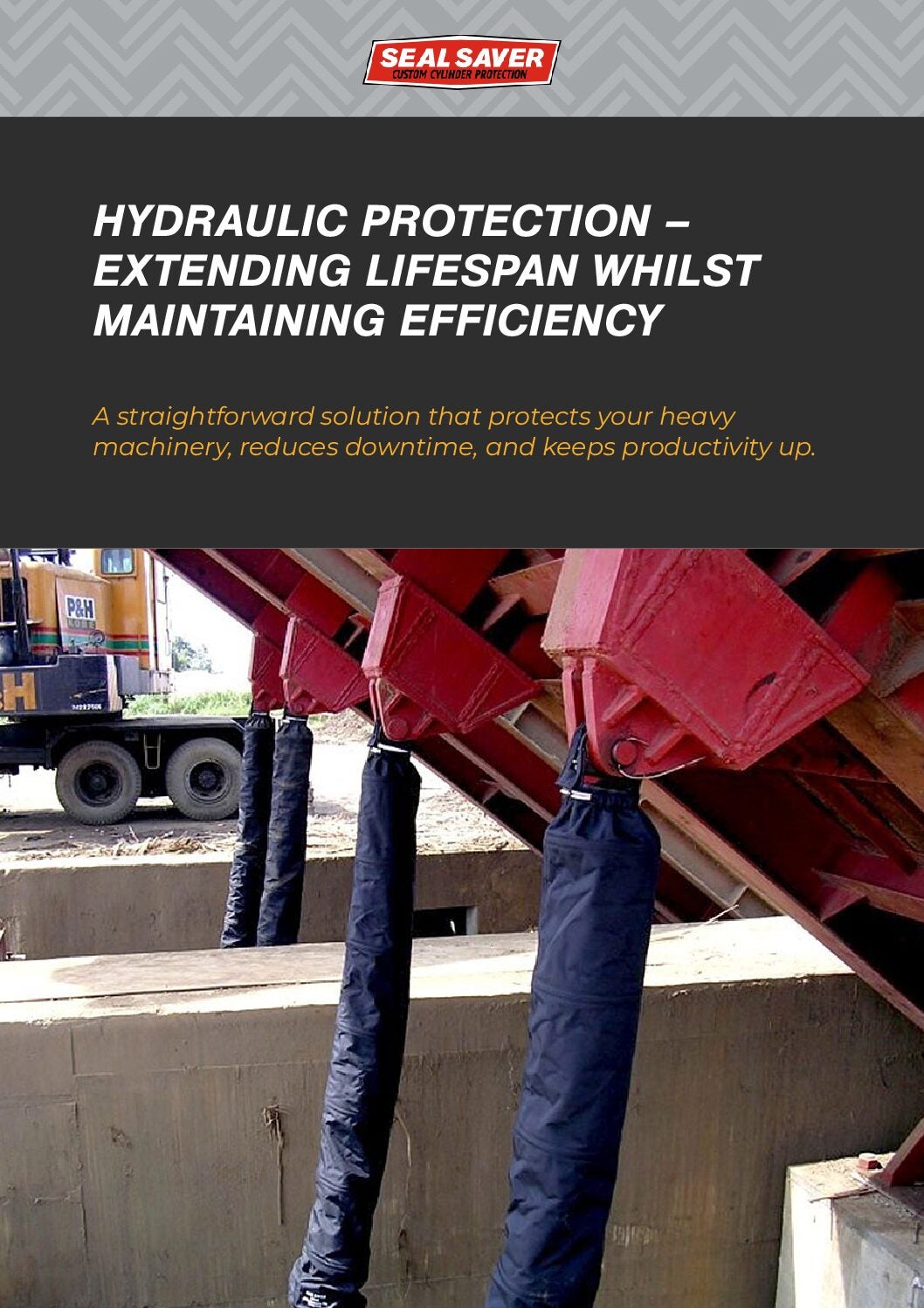

Seal Saver, developed by Fluid Control Services, addresses this challenge through custom-fitted hydraulic cylinder protective boots designed specifically for harsh operating conditions. Installed externally, the boots shield rods and seals from abrasive debris, moisture, and chemicals without interfering with cylinder operation. Importantly, they can be fitted in minutes without dismantling machinery, allowing them to be incorporated into routine maintenance schedules.

“Mining is one of the harshest environments we work in,” Carlson notes. “Abrasive conditions take their toll, but even there, protecting the cylinder prevents far more expensive damage underneath.”

Replacing or resealing a hydraulic cylinder on a mid-sized excavator can cost thousands, whereas a protective boot represents a fraction of that investment and extends cylinder life by up to three times in mining applications.

Seal Saver’s value also lies in its adaptability. Boots are manufactured to match individual cylinder dimensions and can be produced in materials tailored to specific risks, from ballistic nylon for abrasion to specialist fabrics for heat or chemical exposure. Carlson adds: “We ask what the cylinder is exposed to (sharp materials, chemicals, heat) and select the right protection accordingly.”

By reducing the frequency of breakdowns, protective solutions such as Seal Saver help extend operating time between preventative-maintenance intervals, easing pressure on maintenance teams while improving production continuity. In an industry where unplanned downtime can cost tens of thousands per hour, that reliability protects both workers and your bottom line.

As mining operations continue to push towards deeper sites, greater automation, and stricter safety standards, protecting hydraulic systems is no longer optional. Hydraulics may remove complexity from machine design but safeguarding them ensures they continue to deliver the control, stability, and safety benefits they promise. With simple installation, proven durability, and a focus on preventive maintenance, hydraulic protection has become a quiet yet essential contributor to safer mining operations worldwide.

To find out more about how Seal Saver can extend the longevity of your heavy machinery in the mining and marine industries, download the whitepaper below.