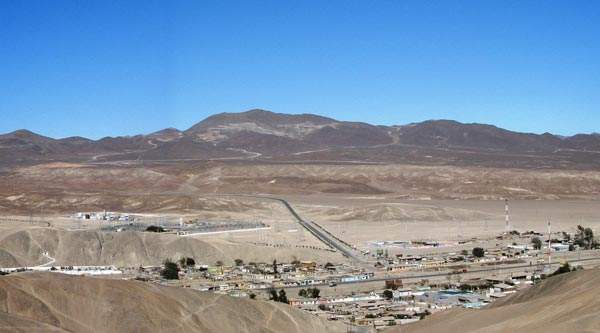

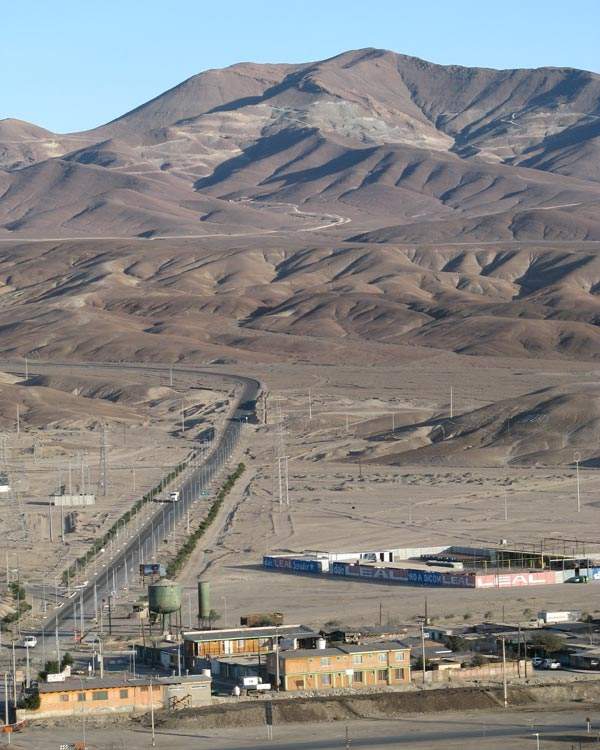

Santo Domingo is a copper-iron-gold mine located near the town of Diego de Almagro in Region III of Chile. Owned by Capstone (70%) and Korea Resources Corporation (30%), it has the potential to be a long-life copper and iron ore producer.

The pre-feasibility study was completed in 2008 by Ausenco, which estimated the mine could have an annual production of 144 million pounds (lbs) of copper, 4.1mt of iron concentrate and 15,000 ounces (oz) of gold.

Environmental impact study for the project is currently being carried out by Knight Piésold. Capstone awarded the feasibility study contract to AMEC in January 2012. The feasibility study is expected to be completed by 2013. The mine is expected to commence production in late-2015.

Geology and indicated reserves at the IOCG belt-based mine

Santo Domingo is part of the Iron-Oxide-Copper-Gold (IOCG) belt in northern Chile. The IOCG belt stretches to about 1,200km and contains several copper deposits.

The Santo Domingo mine is of the Punta del Cobre Formation and contains four deposits – Santo Domingo Sur, Iris, Iris Norte and Estrellita. It includes intercalated and interfingered sequences of volcaniclastics, andesite flows, limestone and calcareous sedimentary rocks.

Indicated resources at the mine are estimated at 486mt grading at 0.32% Cu, 0.043g/t Au and 27.2% Fe. Total inferred resources are estimated at 61.3mt grading at 0.19% Cu, 0.025g/t Au and 25.7% Fe.

Mineralisation of copper at the Santo Domingo Sur (SDS) deposit

Copper mineralisation at the Santo Domingo Sur (SDS) deposit appears in the form of chalcopyrite-bearing specularite-magnetite mantos in the tuff sequence.

Related project

Mara Rosa Gold Project, Goiás, Brazil

The Mara Rosa Project is a gold mine located in the Mara Rosa village, in the state of Goiás in Brazil.

Mineralisation is strongly developed in the northern part of the deposit. The Iris deposit is 500m wide and contains iron oxide mantos and breccias. The main iron oxide mineral at the deposit is hematite and copper mineral is chalcopyrite.

The Iris Norte deposit is located 600m north of Iris deposit. Mineralisation at Iris Norte occurs in the form of magnetite and hematite mantos contained in a sequence of andesitic tuffs and flows.

Estrellita contains both flat-lying and steeply-dipping mineralised structures hosted by andesitic porphyries. Copper mineralisation occurs in the form of brochantite, chrysocolla, pitch limonite, cuprite and chalcocite.

Open-pit mining and processing at the Chilean Santo Domingo deposit

Santo Domingo is part of the Iron-Oxide-Copper-Gold (IOCG) belt in northern Chile.

Santo Domingo mine will be developed as an open pit operation. Conventional mining methods of drilling and blasting will be used for the mining operations. Equipment at the mine will consist of diesel hydraulic shovels and trucks for carrying the ore. SDS deposit will be mined first, followed by Iris and Iris Norte.

A process plant with an annual throughput capacity of 63,500t/d will produce copper concentrate. The process plant will use SAG and ball milling, along with conventional flotation. Low intensity magnetic separation (LIMS) will be used to recover magnetite iron from the copper rougher tailings. The process plant will also include a pipeline to supply seawater from the coast.

Ore processing techniques at Capstone and Korea Resources Corp’s mine

Produced ore is crushed using a primary gyratory crusher to a nominal size of 100mm.

Crushed ore is sent to the stockpile through a conveyor. From the stockpile, the crushed ore is transported to the SAG mill for processing in a closed circuit with pebble crushing.

The processing plant includes two 12MW ball mills which can grind the ore to a size of 180μm. The ore goes through two stages of rougher floatation. It is then passed through three stages of copper cleaner floatation to produce copper concentrate, which is sent to the copper concentrate stockpile.

Iron is recovered from the copper flotation rougher tailings through magnetic separation and floatation circuit. Recovered magnetite is filtered and stored at the magnetite stockpile. Tailings from the ore processing is sent to the tailings storage facility.

Transportation and handling of processed copper and iron concentrate

The mine is located near several infrastructure facilities including a highway, railway line and a port. Processed copper and iron concentrate will be transported to the coast through a 70km pipeline for exportation.

Related content

Esperanza Copper-Gold Mine, Chile

The Esperanza copper-gold project, situated in the Sierra Gorda district of Antofagasta, northern Chile, is jointly owned by Antofagasta Minerals (70%) and Marubeni Corporation (30%).

Spence Copper Cathode Mine, Chile

BHP Billiton’s Spence copper cathode project is located 1,700m above sea level in the Atacama Desert in northern Chile, close to the mining town of Sierra Gorda.

Collahuasi Copper Mine, Chile

Collahuasi copper mine is situated in northern Chile, about 180km southeast of the port of Iquique, at an altitude of 4,000m.