The Santa Cruz Graphite Project is an open-pit flake graphite mining development in the state of Bahia in Brazil. It is being developed by Canadian firm South Star Mining which owns the property through its fully-owned subsidiary Brasil Grafite.

A preliminary economic assessment (PEA) for the project was completed in August 2017 which projected a mineable resource of 12 million tonnes (Mt) over an estimated life of mine of 19 years.

Published in March 2020, a pre-feasibility study (PFS) on the project envisaged a 12-year mine life with production ramping up to 25,000 tonnes per annum (tpa) after the first two years. A three-year trial mining licence for the phase one pilot plant operations of the project was granted in January 2021.

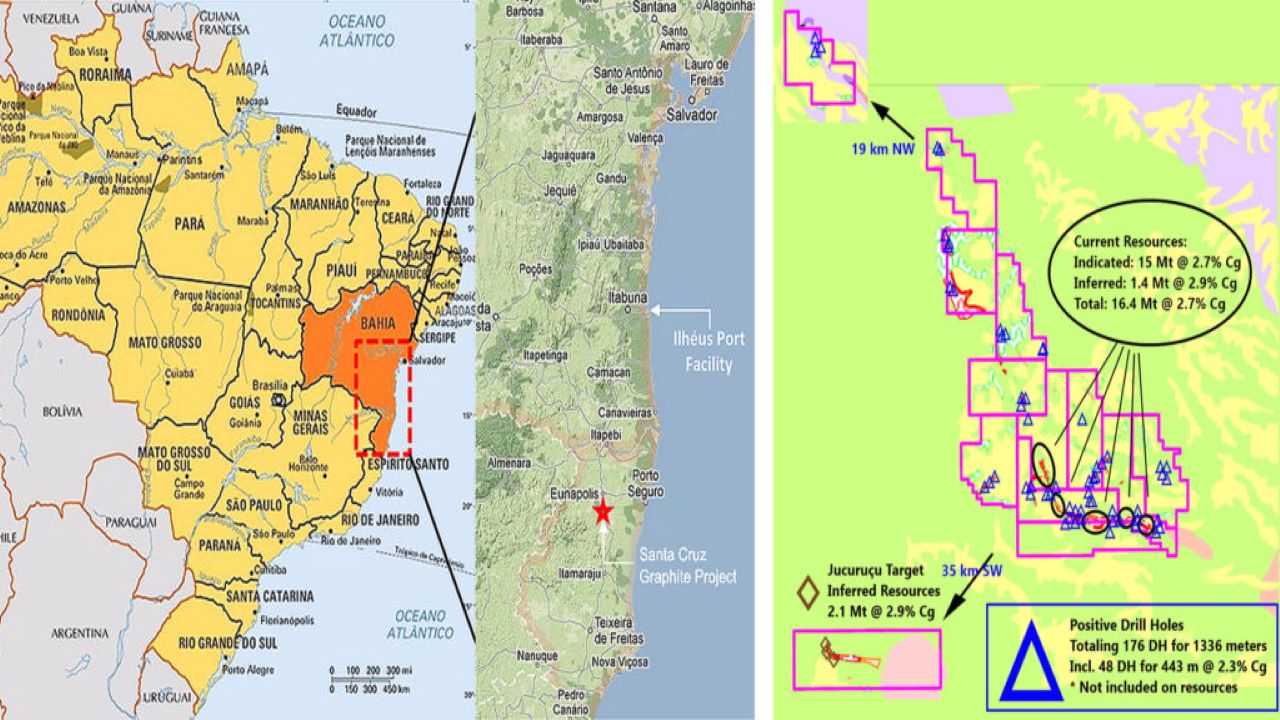

Santa Cruz Graphite Project location and geology

The Santa Cruz Graphite Project is located near the town of Itabela in the southern part of Bahia. The project area encompasses 13 exploration licences covering an area of approximately 13,000ha.

The deposit is located in the Araçuaí Orogen belt, which is an orogenic domain along the southeastern margin of the São Francisco Craton. The project is hosted in the core of the orogen, and the zones are dominated by outcrops of gneisses and paragneisses of the Jequitinhonha or Paraiba do Sul complex.

Santa Cruz Graphite project mineralisation and reserves

Mineralisation at the Santa Cruz Graphite Project is hosted in paragneisses with amphibolite-granulite grade metamorphism with intense anatexis. It extends along an 8km-long continuous strike with widths varying between 30m and 200m with the ore body open at depth and along strike.

The proven and probable mineral reserves at the project were estimated at 12.3Mt grading 2.40% carbon graphite (Cg) containing 295,400t of in-situ graphite, as of July 2019.

Mining methods

The Santa Cruz Graphite Project will employ conventional open-pit mining methods using hydraulic excavators, dozer and haul trucks. The resources in the current mine plan are generally within a shallow, oxidized zone which enables excavation and will not require drilling and blasting operations.

Auxiliary mining equipment to support the operations will include a CAT D8 bulldozer or its equivalent, a wheel dozer, a grader, a water truck, maintenance vehicles, and service vehicles. The haul fleet will include 25t trucks. Access roads for the transportation of ore, waste, and tailings are estimated to be constructed with 10m width and a maximum grade of 10%.

Excavators will be used to load the haul trucks that will transport the ore to the plant ore stockpile area and the waste to the waste storage facilities (WSF). The mining operations will be implemented only during the dry season to minimise the negative impact of excessive moisture on the handling, as well as mining difficulties.

The waste rock will be compacted, along with the installation of surface drainage and revegetation to ensure the long-term physical and chemical stability of the deposit and facilities.

Mineral processing at Santa Cruz Graphite Project

The mineral processing facilities will be developed in two phases. Phase one will involve the construction of a pilot plant with a processing capacity of 5,000tpa. The pilot plant will be operated for a period of up to two years before the commencement of phase two, which will involve the installation of an additional plant to increase the total processing capacity of the project to 25,000tpa.

The run of mine (RoM) ore will undergo crushing in a primary jaw crusher. The crushed ore will be separated into the +50 and -50 mesh circuits via a wet screener. The crushed ore in the +50 mesh circuit will undergo grinding using a ball mill, steel shot, and pebble crusher while the -50 mesh will undergo grinding using steel shot prior to flotation.

The milled product will be introduced into a flotation circuit after which a screen will separate the material into +30 mesh and +50 mesh for the +50 circuit as well as +80 mesh, +140 mesh, and -140 mesh for the -50 mesh circuit before being filtered, dried and packaged.

The filter press, dryer and packaging system will treat the fines and flake concentrates in batches separately to avoid contamination. The filter press will reduce the product moisture content to approximately 17%.

The filter press product will be introduced into the gas dryers to further reduce product moisture to a maximum of 1%. The final product will be stored in silos and super sacks or 25kg bags prior to shipping.

Santa Cruz project infrastructure

The project is currently accessible via 90km of paved federal highways from the Porto Seguro International Airport.

Electricity for the project is expected to be supplied from either the Itabela or Eunápolis substations.

The water supply requirement will be met from on-site sources with the primary process water requirement planned to be secured from process tailings that will be thickened and press-filtered. Drinking and make-up water will be supplied from artesian wells.

Offtake agreement with South Star Mining

In May 2021, South Star Mining signed a memorandum of understanding (MoU) for the supply of 4,000t of natural flake graphite from the Santa Cruz Graphite Project to an unidentified European partner for a period of four years.

Contractors involved

The pre-feasibility study for the Santa Cruz Graphite Project was prepared by Brazilian company Dompieri Tecnologia em Mineração (DTM), which was also responsible for the preliminary economic assessment of the project in August 2017.