Marban Engineering is an open-pit gold mining project located in Quebec, Canada. The project is being developed by O3 Mining, a gold explorer and mine developer based in Canada.

A pre-feasibility study (PFS) for the project was completed in September 2022 while work on a feasibility study is currently underway and is expected to be completed in the fourth quarter of 2023.

The PFS confirmed Marban Engineering as a high-margin gold project, which is capable of producing 161 thousand ounces (koz) of gold a year for a period of 9.6 years with an estimated pre-production capital investment of C$435m ($326.9m).

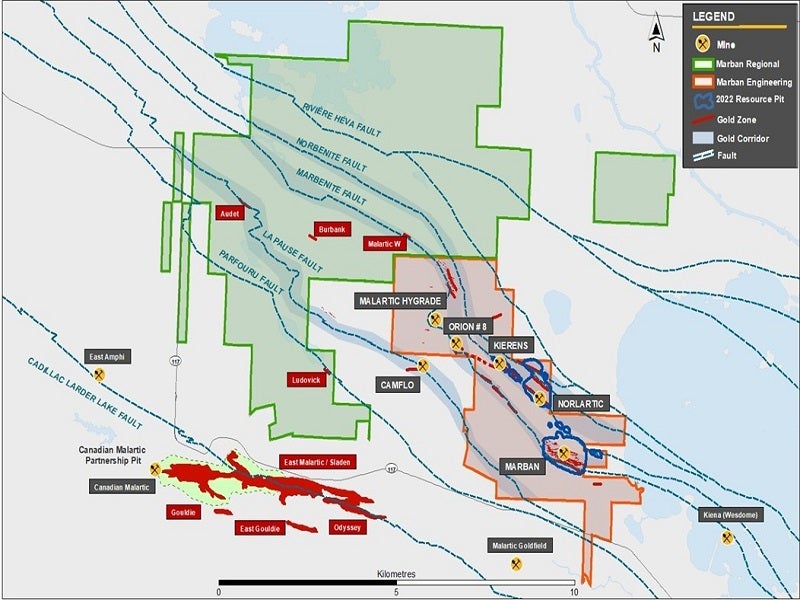

Project location

The Marban property is located in the western portion of the province of Quebec, Canada. It lies nearly midway between the towns of Val-d’Or and Malartic.

The Marban Engineering project covers the south-east portion of the property, with all the north and west parts of the property expected to be developed as part of a broader project called Marban Greenfield.

The entire property comprises 181 mining claims encompassing a total area of 7,702ha.

Geology and mineralisation

The Marban gold project lies within the Malartic mining district in the Abitibi greenstone belt of the Superior Archean craton, in eastern Canada.

The Abitibi greenstone belt straddles the Ontario-Quebec border and is characterised by east-trending successions of folded volcanic and sedimentary rocks and intervening domes of intrusive rocks.

The metavolcanic rocks within the Malartic mining district are composed of allochthonous komatiitic to tholeiitic volcanic suites.

Gold mineralisation at Marban is hosted primarily within the ferriferous basalt or at its folded contact with the magnesian basalt. Mineralisation occurs as quartz and quartz-carbonate-chlorite veins and veinlets with disseminated pyrite and pyrrhotite. The thickness of veins and veinlets varies from one centimetre to a few metres.

Gold reserves at Marban

The Marban Engineering project was estimated to hold 56.43 million tonnes (t) of proven and probable mineral reserves grading 0.91 grams per tonne of gold, as of August 2022.

Mining and processing

The Marban Engineering project is proposed to be developed as a conventional open-pit mining operation, using 10m benches.

The mining fleet will comprise three 16m³ electric hydraulic shovels, one 12m³ diesel electric shovel, and one 10.7m³ diesel front-end loader. A fleet of 150t trucks will be used for ore loading operations, while 100t trucks will serve as secondary overburden loading units.

The Marban processing plant will have a capacity to treat up to six million tonnes of ore a year.

The run-of-mine ore will be crushed in a primary crushing facility consisting of an apron feeder, grizzly feeder, and a jaw crusher. The oversized ore will be fed to a secondary cone crusher.

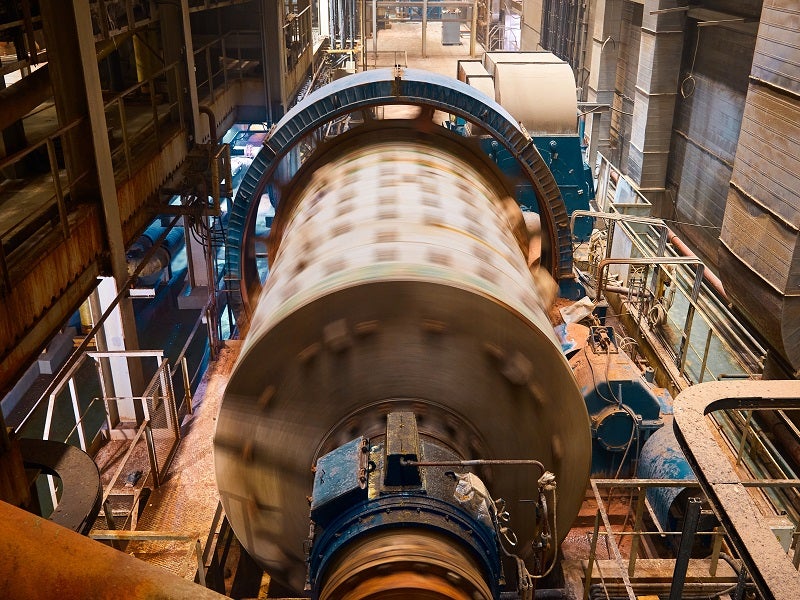

The crushed ore product will be transferred to a semi-autogenous grinding mill followed by a closed-circuit ball mill with hydrocyclones. The ground ore will undergo intensive cyanidation in a gravity circuit comprised of one scalping screen and two centrifugal batch concentrators in parallel.

The centrifugal concentrator will be fed with scalping screen undersize, and the concentrate product will be leached by the intensive cyanidation reactor circuit. The cyclone overflow will be fed to the conventional leach and carbon-in-pulp (CIP) circuit while the underflow will report back to the ball mill.

Gold and silver particles will be dissolved in the leach tanks and adsorbed in the CIP circuit onto activated carbon. The loaded carbon will then be extracted and introduced to a pressure Zadra elution circuit.

Gold and silver precipitates will be recovered by electrowinning in the gold room and dried in an oven. The recovered metals will be mixed with fluxes and smelted in a furnace to produce the final gold ore bars.

Site infrastructure

The Marban property is accessible from Route 117 of the Trans-Canada Highway that links Rouyn-Noranda, Val d’Or and Malartic. A 4km-long new road will also be constructed to the east of the project site to connect to an existing public secondary road (Chemin Gervais) that crosses over the footprint of the Marban pit.

Power required for the project is expected to be sourced from an existing Hydro-Québec 120kV transmission line that traverses the property, adjacent to the process plant location. A 120kV overhead transmission line will be constructed to connect the existing line to a new 120kV outdoor substation near the process plant.

Fresh water will be sourced from the Marban pit and stored in a freshwater tank, which will feed the potable water treatment system, elution circuit, and reagent systems.

Contractors involved

Ausenco Engineering Canada, a subsidiary of Australian engineering business Ausenco, prepared the PFS for the Marban Engineering project. The company also provided the metallurgy and process design, site and tailings infrastructure design, as well as the cost estimate and financial modelling services for the project.

Canada-based mining consultants G Mining Services was engaged to review the infill drilling campaign and associated quality assurance/control data. It was also responsible for the geological modelling, mining design, and mineral resource and reserve estimates for the project.

WSP Canada was responsible for the geotechnical drilling programmes and environmental fieldwork for the PFS.